Electrical connector

A technology for electrical connectors and contact sections, which is applied in the field of multiple injection-molded electrical connectors, can solve the problems of small spacing and difficult positioning of sealing glue, and achieve the effects of easy sealing, stable overall structure, and prevention of injection molding burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

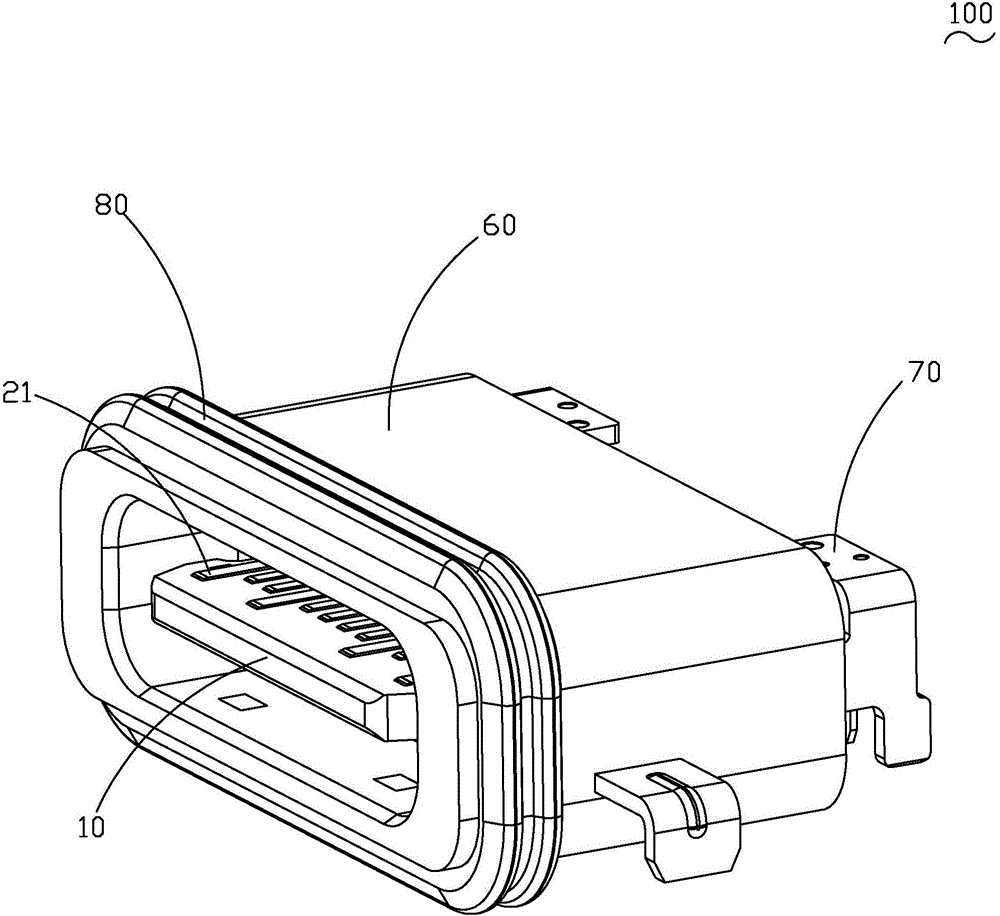

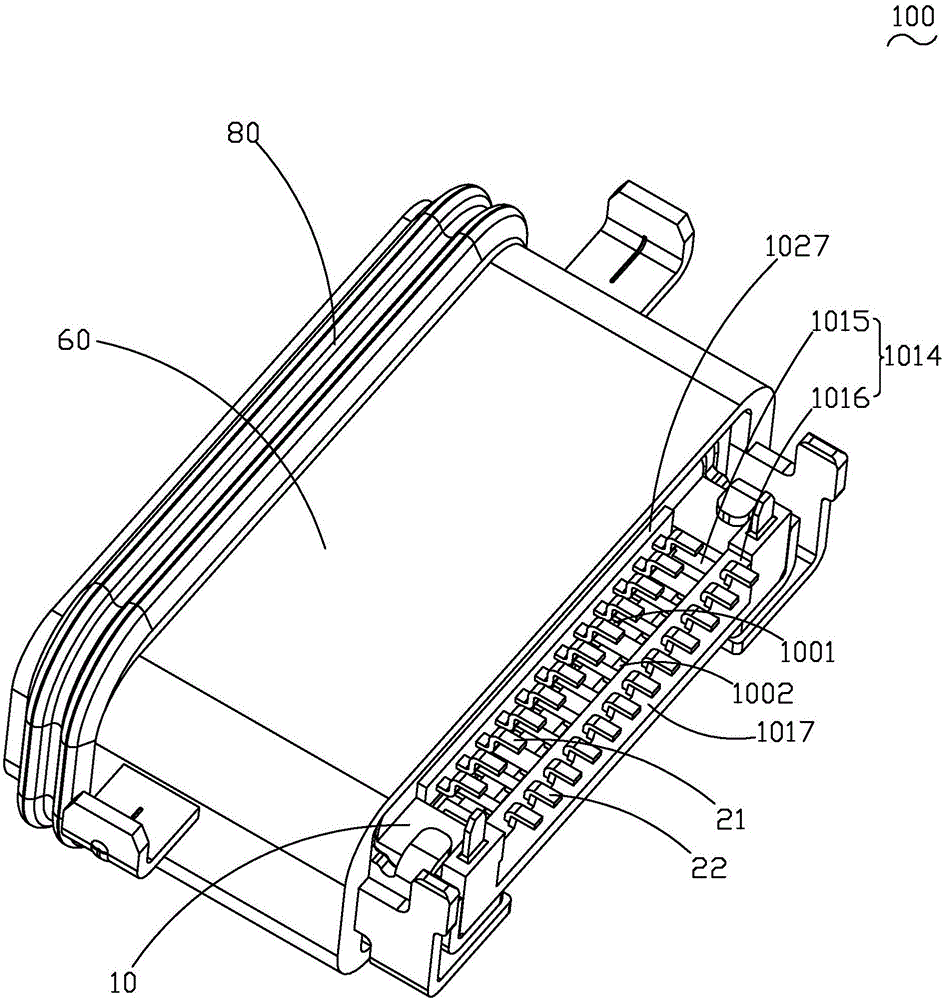

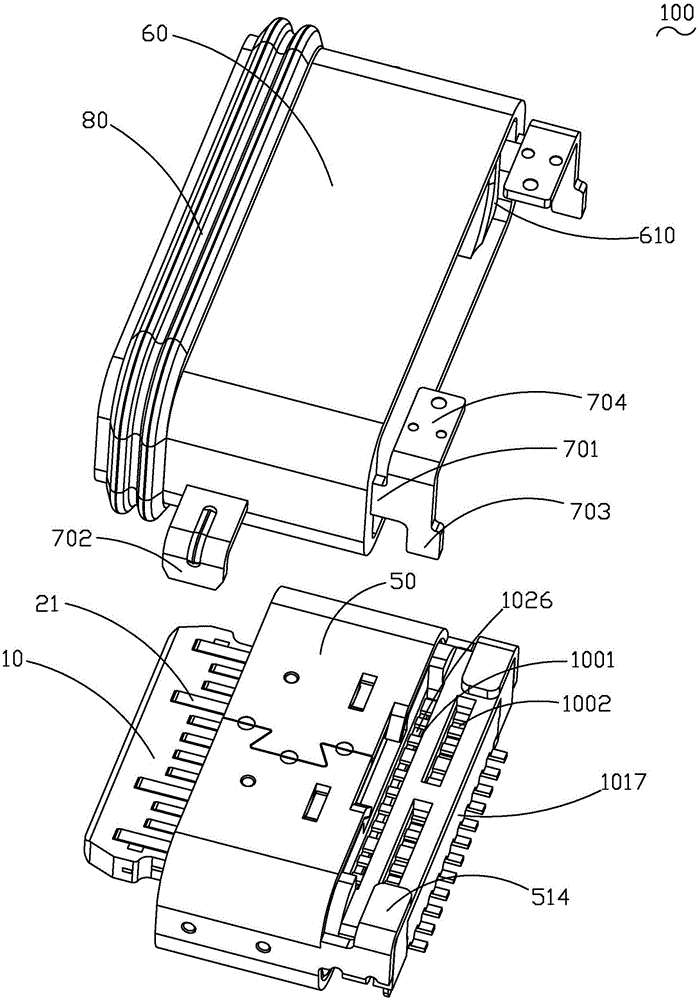

[0034] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, and for the convenience and accuracy of expression, all references to directions in this paper should be referred to figure 1 , the butt end of the docking electrical connector (docking plug, not shown) is the front end, and the other end is the rear end.

[0035] see Figure 1 to Figure 16 As shown, the electrical connector 100 disclosed in the present invention can be sunk mounted on a mating circuit board (not shown) and can be mated with the mating electrical connector. The electrical connector 100 includes an insulating body 10, an upper row terminal group 21 and a lower row terminal group 22 embedded in the insulating body 10, a shielding plate 30 embedded in the insulating body 10 and fixed on the insulating body 10. The metal piece 40 and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap