Method and device for automatic calibration of vehicle-mounted motor

An automatic calibration and calibration technology, which is applied to the estimation/correction of motor parameters, can solve the problems of manual calibration of motor control current, such as high technical requirements, high work intensity, and poor calibration accuracy, so as to increase the number of sampling points and improve work efficiency. , The effect of eliminating reading errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

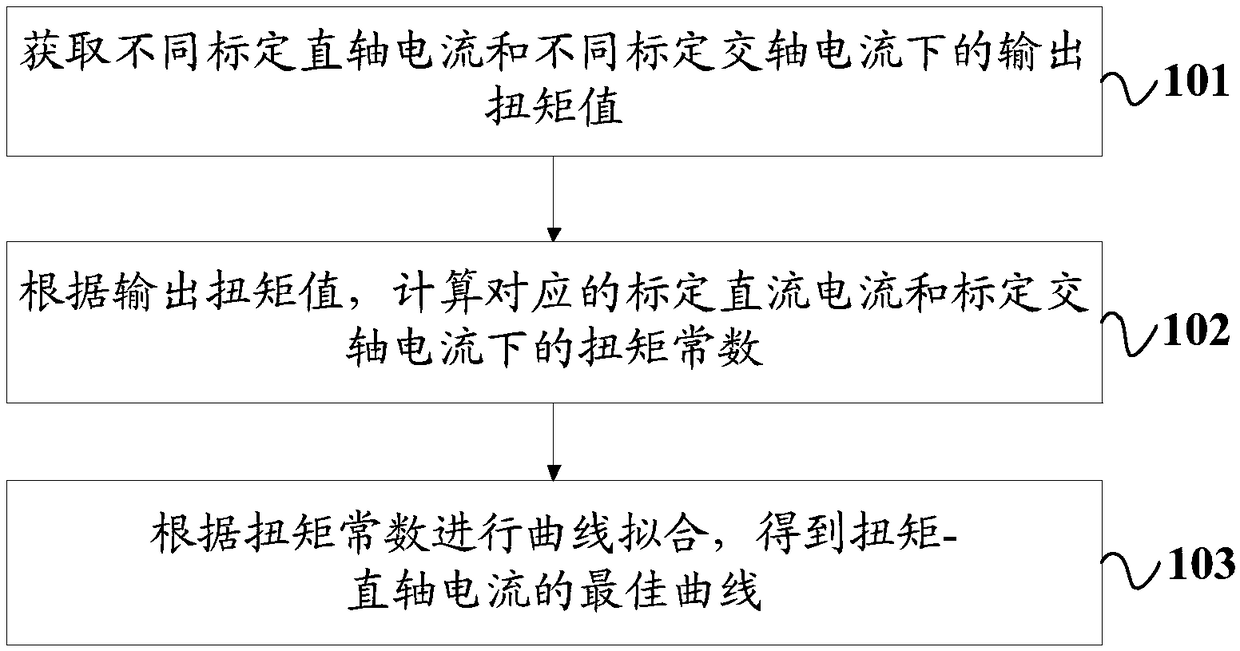

[0044] Such as figure 1 As shown, the embodiment of the present invention provides a method for automatic calibration of a vehicle-mounted motor, which specifically includes the following steps:

[0045] Step 101: Obtain output torque values under different calibrated direct axis currents and different calibrated quadrature axis currents.

[0046] In order to improve the calibration accuracy, as many calibration direct-axis currents and calibration quadrature-axis currents as possible should be set. Generally, the output torque values are different under different direct-axis currents and quadrature-axis currents.

[0047] Specifically, before step 101, it also includes: configuring the initial direct-axis current, the step size of the direct-axis current, the initial quadrature-axis current, and the step-size of the quadrature-axis current; Current; different quadrature currents are determined according to the initial quadrature current and the step size of the quadratur...

Embodiment 2

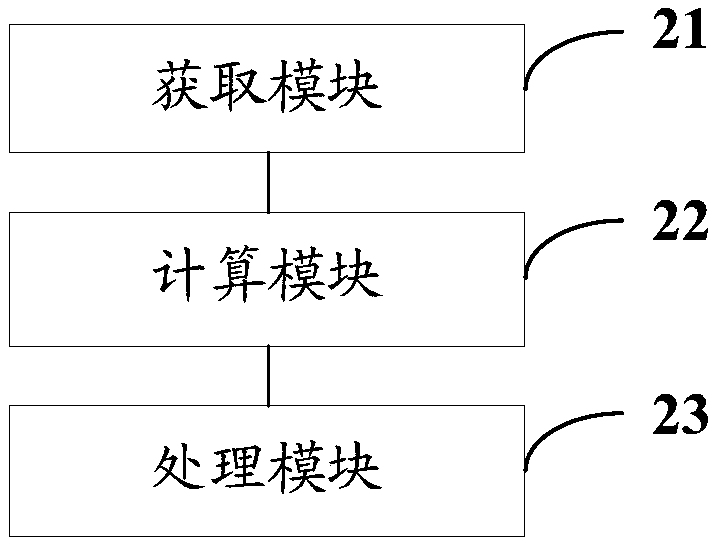

[0064] The first embodiment above introduces the automatic calibration method of the vehicle-mounted motor of the present invention, and the following embodiment will further introduce its corresponding device in conjunction with the accompanying drawings.

[0065] Specifically, such as figure 2 As shown, embodiments of the present invention provide a vehicle-mounted motor automatic calibration device, including:

[0066] An acquisition module 21, configured to acquire output torque values under different calibrated direct-axis currents and different calibrated quadrature-axis currents;

[0067] Calculation module 22, used to calculate the torque constant under the corresponding calibrated DC current and calibrated quadrature axis current according to the output torque value;

[0068] The processing module 23 is configured to perform curve fitting according to the torque constant to obtain an optimal torque-direct axis current curve.

[0069] Among them, the vehicle-mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com