Ultrasonic flow probe and method of monitoring fluid flow in a conduit

A fluid flow and ultrasonic technology, which is used in the field of ultrasonic flow probes for monitoring fluid flow in pipes such as exhaust pipes and monitoring fluid flow in pipes, which can solve the problems of low signal-to-noise ratio and poor ultrasonic signals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

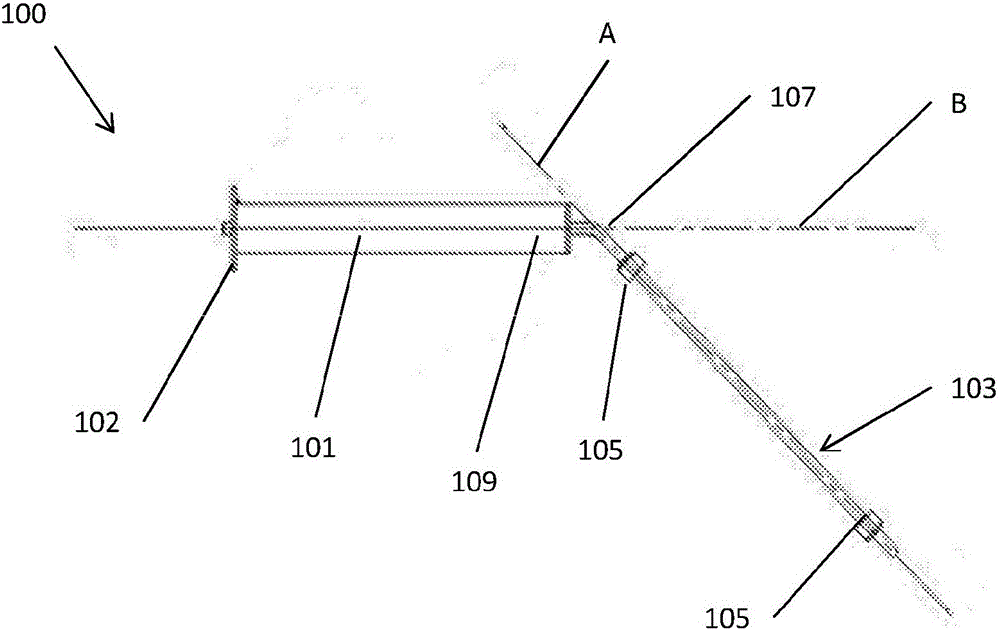

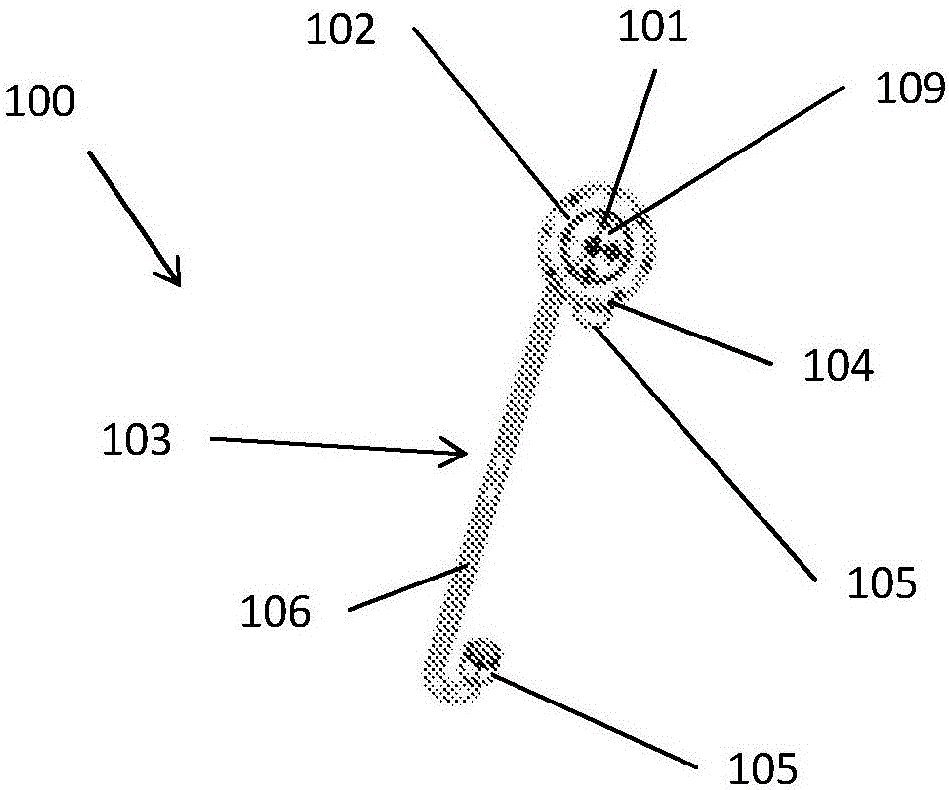

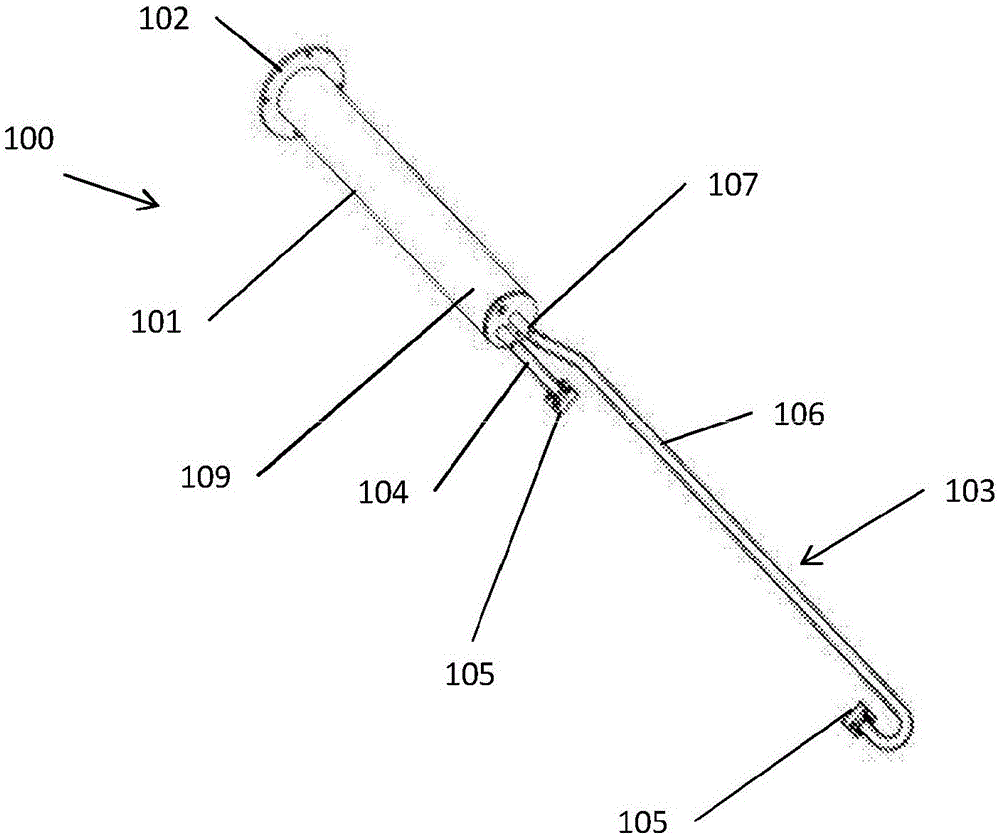

[0033] figure 1 , figure 2 and image 3 The ultrasonic flow probe 100 of the first embodiment is shown, which includes: a mounting part 101 , a bracket 103 mounted on the mounting part 101 , and two ultrasonic transducers 105 mounted on the bracket 103 .

[0034] The mounting part 101 is a cylindrical part. When the probe 100 is mounted on a surface, the mounting part extends away from the surface, and the axis of the cylinder is aligned along the mounting axis B. As shown in FIG. One end of the mounting member 101 is provided with a mounting plate 102 which is mounted on the surface on which the probe 100 is mounted. For example, mounting plate 102 may be affixed to or pass through the surface. In this embodiment, the mounting axis B is perpendicular to the mounting plate 102 due to the alignment of the mounting plate 102 with the surface.

[0035] The stand 103 includes two arms 104 , 106 . One end of each arm 104 , 106 is mounted to the free end of the mount 101 . An u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com