Movement of fuel tubes within the array

A fuel tube and array technology, which is applied in the assembly of fuel elements, reactor fuel elements, and control of nuclear reactions, etc., can solve the problems of increasing the size of the reactor and the cost of resources, and the inability to use molten salt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

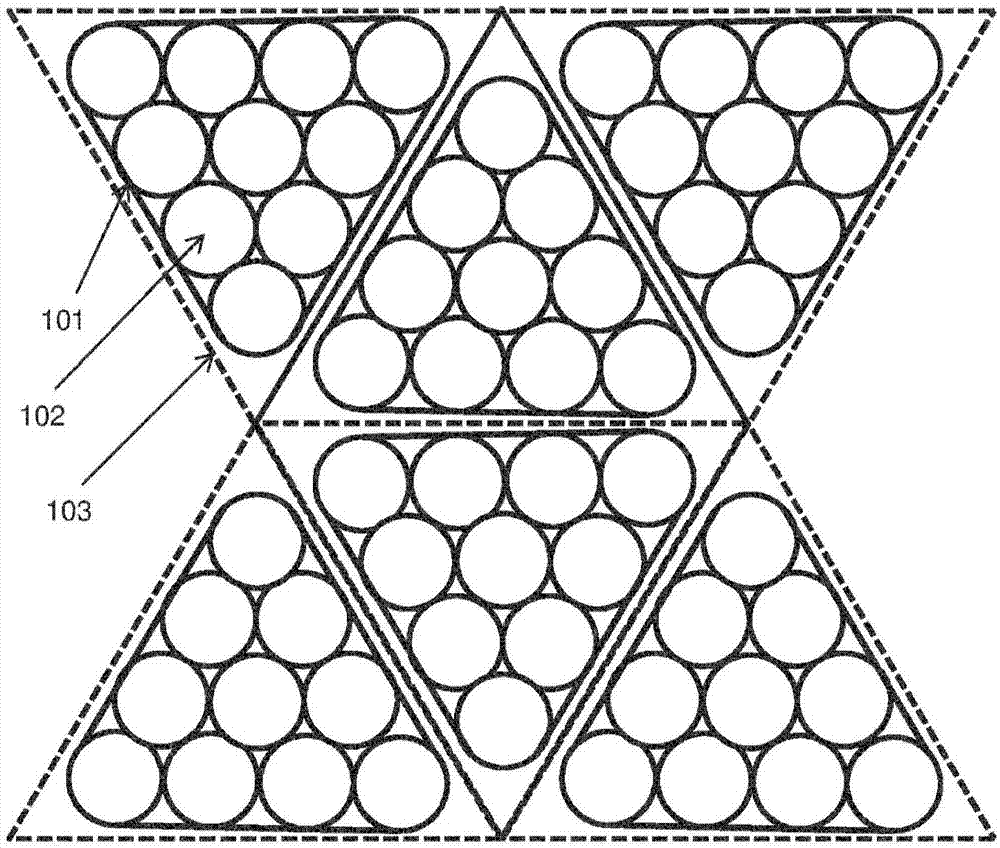

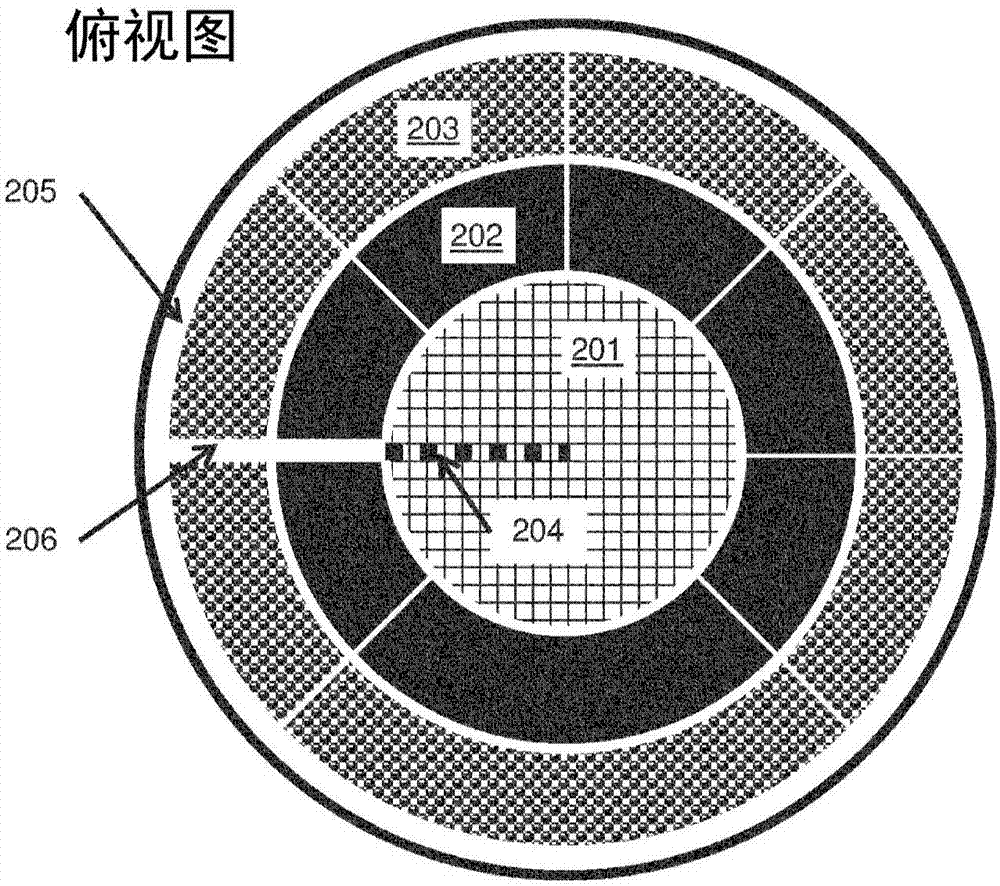

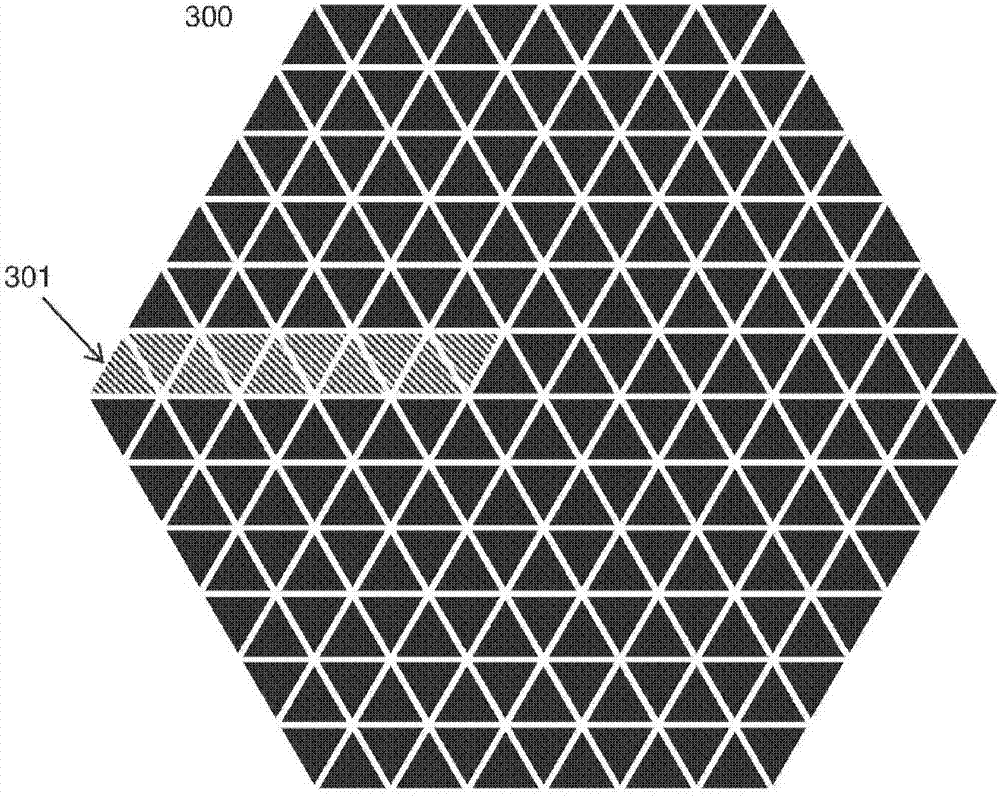

[0014] In order to solve the above problems and allow the reactor to operate efficiently, a solution is proposed whereby the vertical fuel tubes can be moved within the array and removed from the array without the need to lift the vertical fuel tubes above the array. For convenience, the array is divided into multiple fuel assemblies that can move horizontally. Coordinated movement of these fuel assemblies can result in fuel tube movement toward the center of the array as fuel is depleted, and fuel tubes with less than a minimum level of fissile / fertile material move out of the array along an "exit row". New fuel tubes can be added at the outer edge of the array. In this way, the concentration of fissionable material varies with location substantially throughout the life of the reactor.

[0015] Each fuel assembly defines an array cell, an area that surrounds the fuel assembly and does not contain any portion of another fuel assembly. These cells may have any shape of horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com