Plant Protection Fertilizer Sprayer

A fertilizer spraying and plant protection technology, applied in fertilization devices, fertilizer distributors, agriculture, etc., can solve the problems of uncontrollable spreading range, inability to ensure uniform spreading, and large fertilizer spreading range, so as to improve the efficiency of fertilizer spraying operations and facilitate replacement , The effect of spraying fertilizer evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

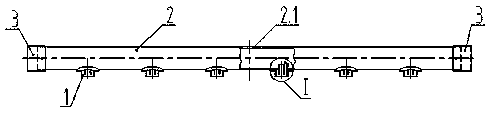

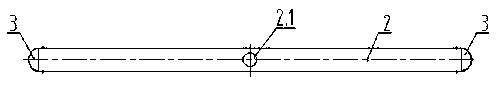

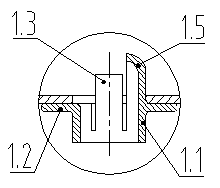

[0023] The fertilizer spraying pipe of the plant protection fertilizer spraying machine shown in the accompanying drawing includes a fertilizer spraying pipe 2 and a fertilizer spraying nozzle 1; several fertilizer spraying nozzles 1 are arranged on the lower side of the fertilizer spraying pipe 2; the fertilizer spraying pipe 2 is a horizontal tubular member The fertilizer spraying pipe 2 is provided with an air inlet 2.1 on the pipe wall; the fertilizer spraying nozzle 1 is an integrated sleeve-shaped member with a flanging flange, including a flange 1.2, a tubular spout 1.1 at the bottom of the flange 1.2; flange 1.2 and The upper end surface 1.2.1 of the pipe wall of the fertilizer spraying pipe 2 is a circular arc surface consistent with the radius of the outer wall of the fertilizer spraying pipe 2; part of the pipe wall on both si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com