Washing agent box and washing machine

A detergent box and detergent dispensing technology, applied in the field of washing machines, can solve the problems of increasing the friction between the drawer and the box body, affecting the user experience, inconvenient operation, etc., so as to prolong the dissolution time, promote the dissolution and release bubble, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

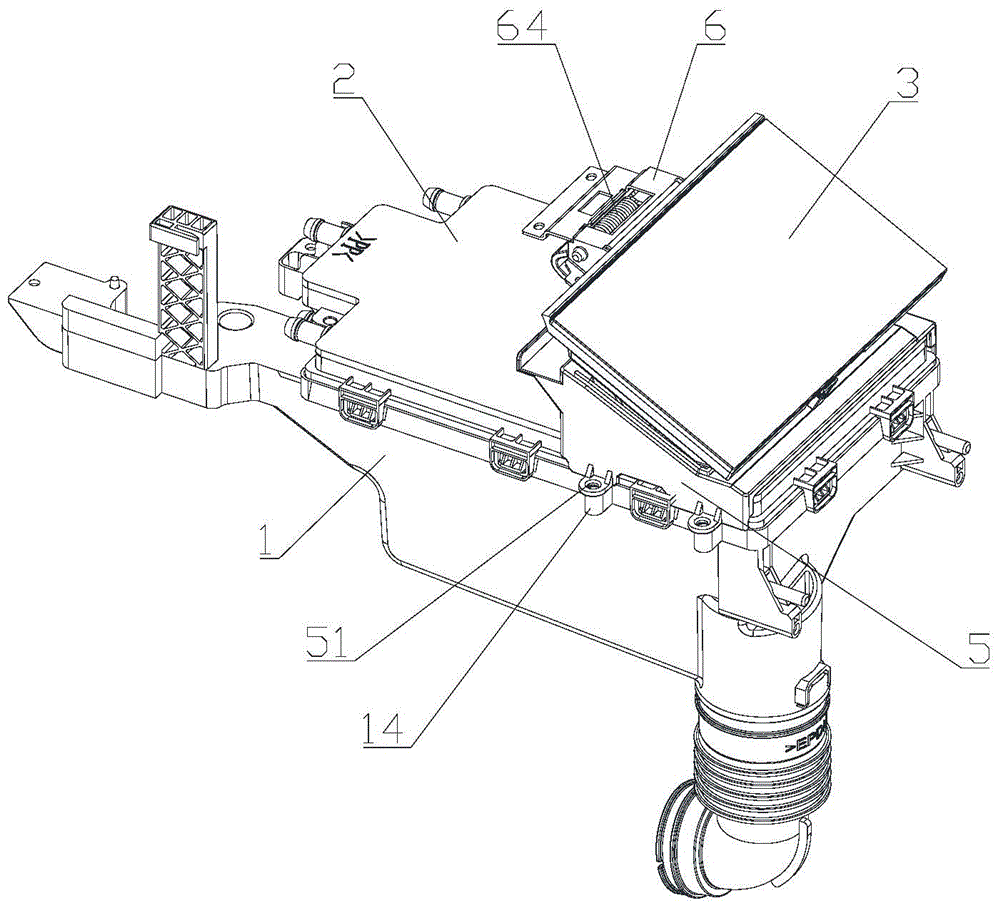

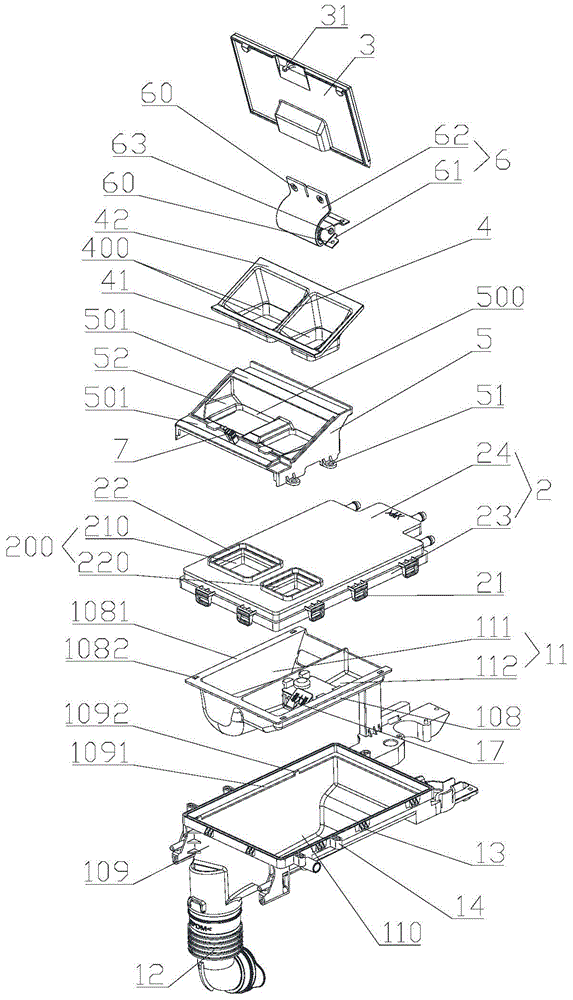

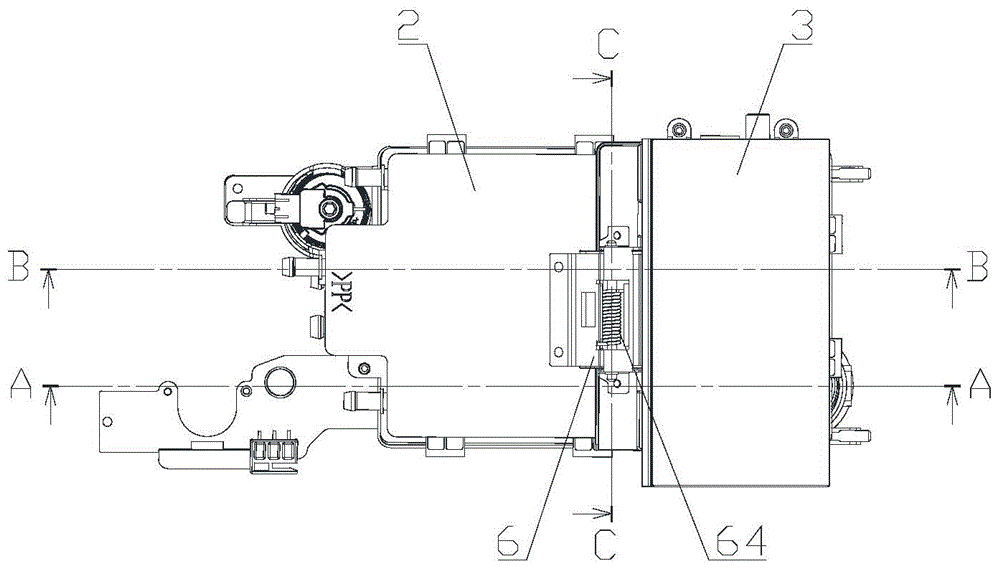

[0036] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention firstly provides a detergent box, which includes a box body 1 and a water spray assembly 2. The box body 1 is provided with a detergent injection chamber 11 and a water outlet 100, and the water outlet 100 communicates with the detergent injection chamber 11. The water outlet 100 is connected with a water outlet pipe 12 that discharges liquid to the bucket. The water spray assembly 2 is installed on the top of the box body 1 and sprays water into the box body 1. In this embodiment, the water spray assembly 2 is snap-fitted. On the top of the box body 1, specifically on the outside of the water spray assembly 2, a plurality of buckle rings 21 are arranged, and the buckle rings 21 are distributed around the outer circumference of the water spray assembly 2, and corresponding buckle protrusions 13 are set on the outside of the top of the box body 1 , the buckle protrusion 13 snaps into...

Embodiment 2

[0050] The present invention also provides a washing machine, such as Figure 9 , Figure 10 and Figure 11 As shown, taking the drum washing machine as an example, it includes a box body 9 and a control seat 8, the control seat 8 is installed on the box body 9, the control seat 8 is provided with a panel mounting plate 81, and the panel mounting plate 81 is equipped with a touch panel 82. The seat 8 is provided with a detergent box, the detergent box adopts the basic structure of the first embodiment, the box body 1 is installed on the control seat 8, and the panel mounting plate 81 is provided with a mounting hole 810, and the mounting hole 810 is correspondingly located in the delivery through hole 200 Above, the cover plate 3 cooperates with the installation hole 810 to close or open the delivery through hole 200 .

[0051] In this embodiment, since the detergent box is installed on the control seat before the panel control board, if the cover plate is connected to the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com