Combine harvester operation state online monitoring system

A technology of combine harvester and operation status, which is applied in the fields of harvesters, agriculture, cutters, etc., can solve the problem of lack of speed monitoring of key rotating shaft components, where faults often occur, and is not conducive to the accurate judgment of combine harvesters. Solutions and other problems, to achieve the effect of high fault detection accuracy, convenient installation and simple wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

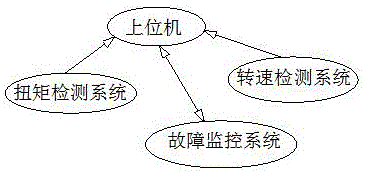

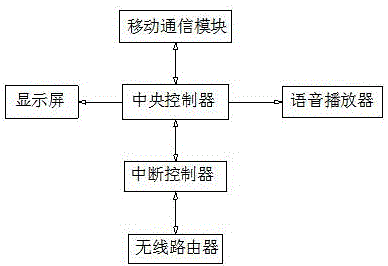

[0023] Such as figure 1 Shown, a kind of combined harvester operation state on-line monitoring system, comprises the host computer that is equipped with LabVIEW system, torque detection system, rotational speed detection system and fault monitoring system; Described host computer comprises central controller, and described central controller respectively A mobile communication module, an interrupt controller and a touch display based on LabVIEW are connected; the interrupt controller is connected with a wireless router;

[0024] The torque detection system includes a first wireless data collector and wireless torque sensors respectively installed on the engine shaft, the threshing drum shaft, the conveying shaft, the feeding auger shaft and the puller shaft; each wireless torque sensor is connected to the first The corresponding acq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com