A floor system laying method for computer room construction

A laying method and flooring technology, which is applied to local raised floors, buildings, building structures, etc., can solve problems such as large expansion, and achieve the effects of convenient use, high installation efficiency, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

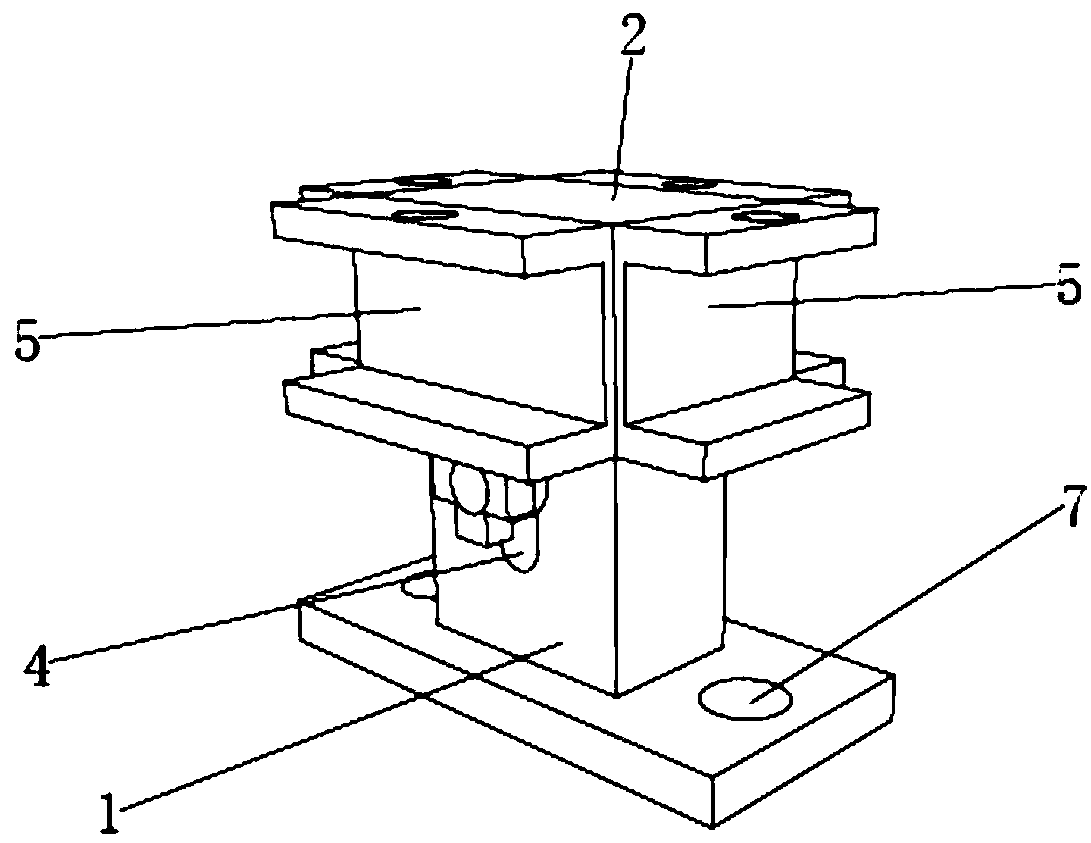

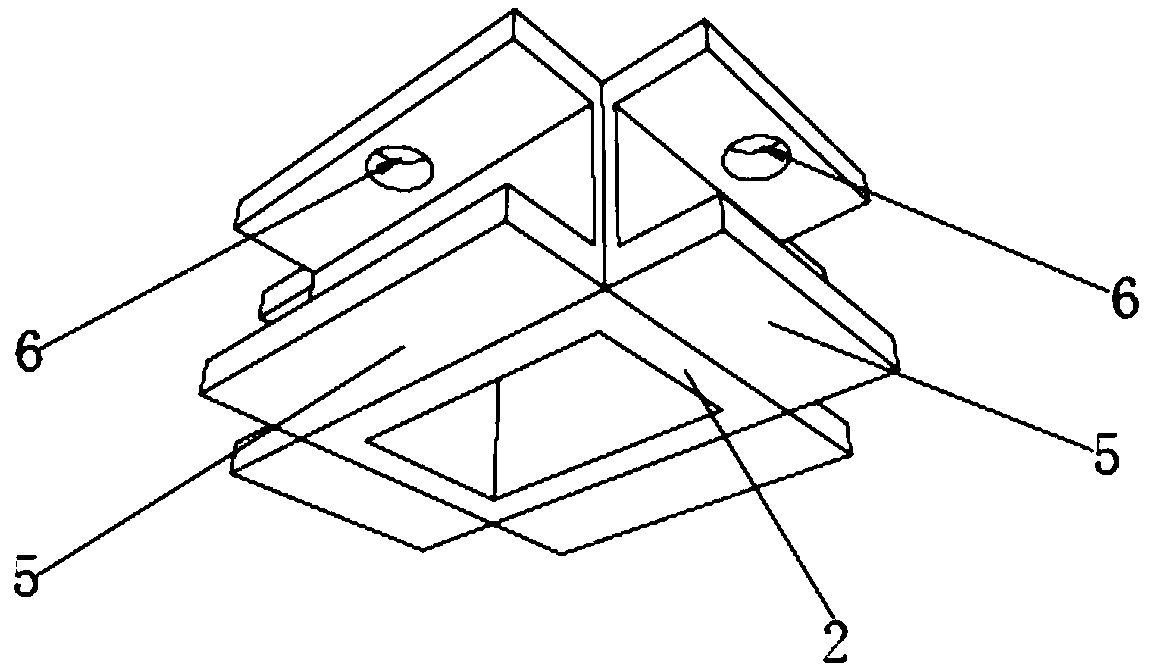

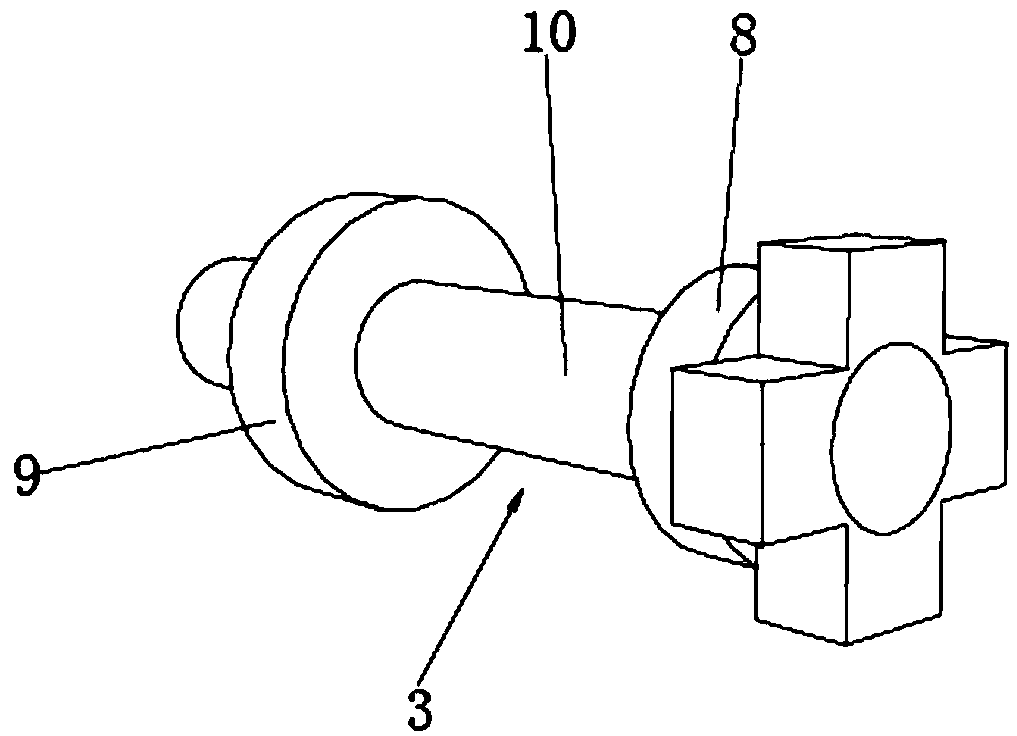

[0036] Such as Figure 1 to Figure 7 As shown, a floor system laying method for machine room construction includes the following steps:

[0037] (a) Base treatment: clean the surface of the base, remove dust and sundries, check the flatness of the base and the verticality of the corner. The flatness deviation is less than 2mm, and the position where the flatness deviation is greater than 2mm is leveled with cement or quick powder to ensure that the base layer is flat and has no slope, thereby improving the installation accuracy of the floor. Ensure that the base layer is flat, clean, free of cracks and dry. Then paint on the surface of the base, and survive three times. The method of painting the surface of the base is to scrape the putty on the surface of the base first, polish it twice, then apply a layer of environmentally friendly high-grade anti-static paint, reapply the putty and then polish it. Apply a layer of anti-dust paint to prevent leakage and block current tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com