Weighing system capable of distinguishing vehicle type

A weighing system and vehicle type technology, which is applied in the field of weighing systems for vehicle type identification, can solve the problems of tire identifiers being unable to accurately identify vehicle types, measurement errors, and inconsistency between front and rear tires. The effect of overload and strong magnetic field signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A working method of a weighing system, comprising:

[0054] a. The digital weighing signal is filtered by a Caesar window low-pass filter, and the cut-off frequency is set to 10Hz;

[0055] b. Carry out sliding mean filtering on the digital weighing signal within the range of 0-10HZ after low-pass filtering, among which, set the minimum frequency and maximum amplitude of the sliding average filtering, that is, within the minimum frequency and not greater than the maximum amplitude The value of the digital weighing signal is filtered by sliding mean to obtain the weight data.

[0056] Wherein, the minimum frequency is 0.5HZ (2 seconds), and the maximum amplitude is twice the weight division value set by the weighing system.

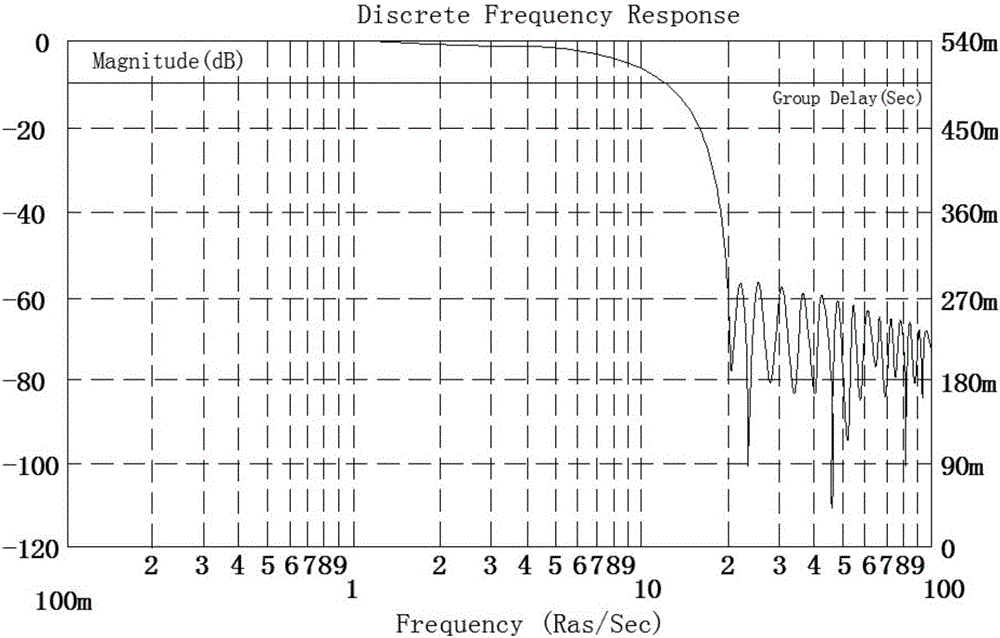

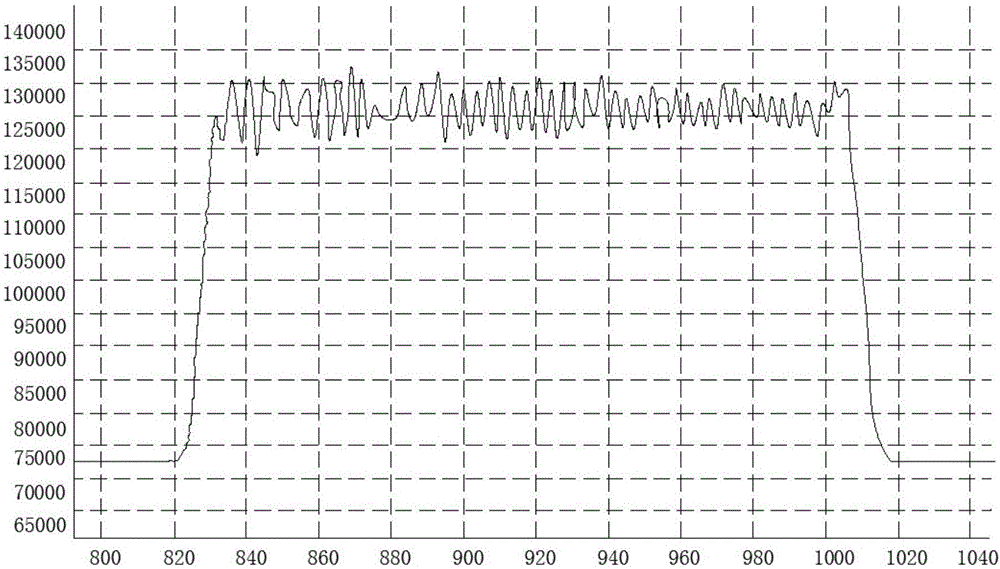

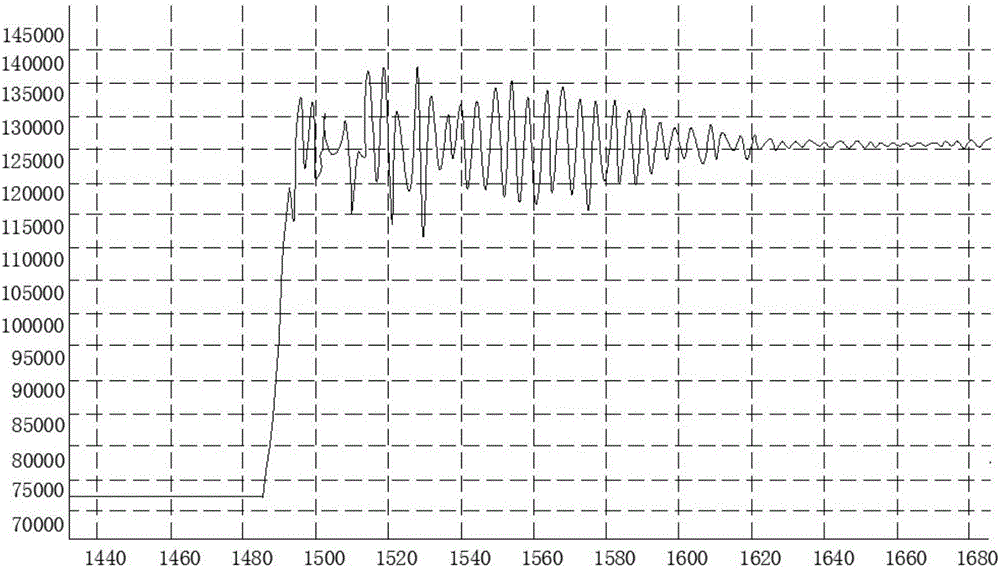

[0057] The Caesar window low-pass filter is set with a sampling frequency of 50Hz, a cutoff frequency of 10Hz, and an order of 16, such as figure 1 shown, from figure 2 It can be seen that the filter basically does not attenuate the signal below...

Embodiment 2

[0085] See Figure 4-7 , a weighing system suitable for vehicle type discrimination for the working method of the weighing system, the weighing system includes a vehicle type detection device 10, and the vehicle type detection device 10 is installed in the weighing area of the weighing platform 9 9-1 (see Figure 4 The dotted line indicates the center position of the area);

[0086] The vehicle type detection device 10 includes:

[0087] The magnetic bias generating device is used to generate a bias magnetic field 5 with stable spatial distribution, and the direction of the loop formed by the magnetic field lines of the bias magnetic field 5 ( Figure 4 The arrow in A indicates the direction) and the direction in which the weighing vehicle travels to the weighing area 9-1 ( Figure 4 The middle B arrow indicates the direction) is consistent and covers the upper space of the weighing area 9-1. If the magnetic field strength is large, it can be completely covered. If the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com