Automatic needle discharge type multi-sample gas-liquid sampler based on negative pressure sampling method

A technology of gas-liquid sampling and sampling method, applied in sampling, sampling devices, instruments, etc., can solve the problems of low efficiency, cumbersome efficiency, low efficiency, etc., and achieve the effect of convenient installation layout, small size, and easy replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

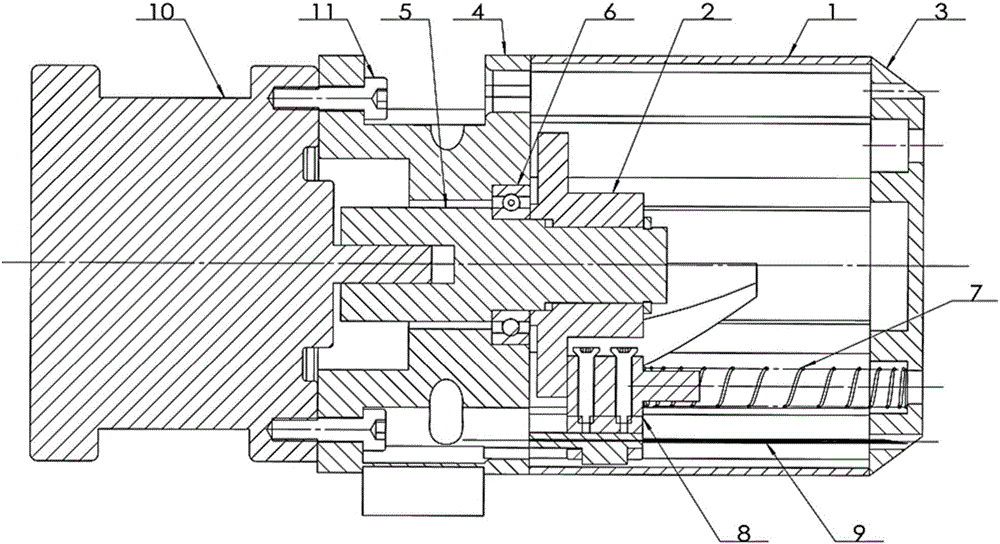

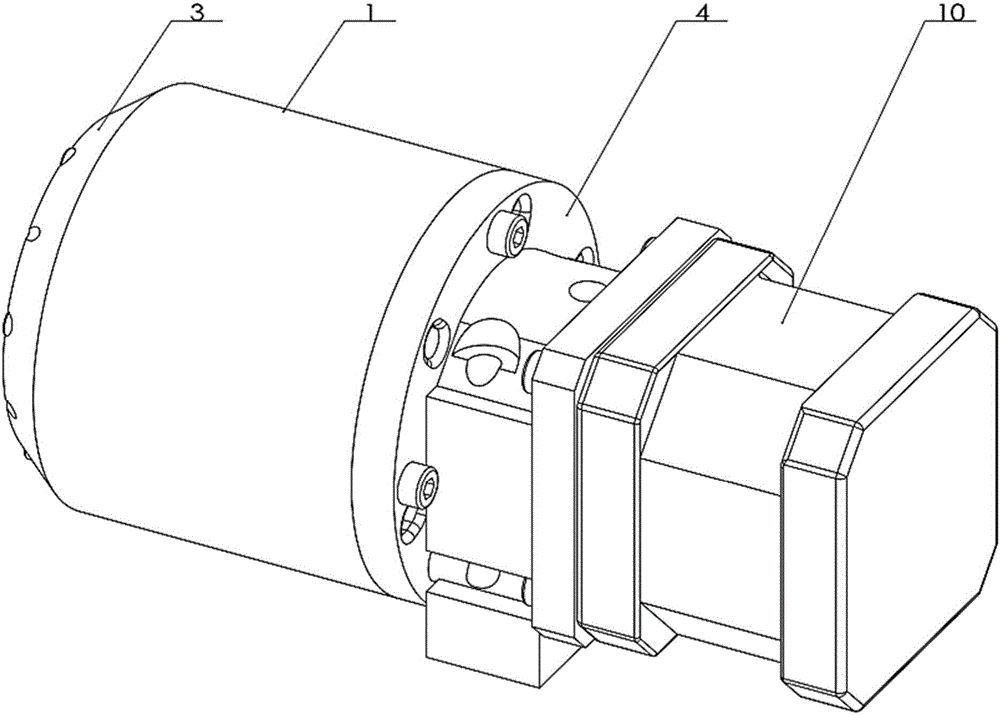

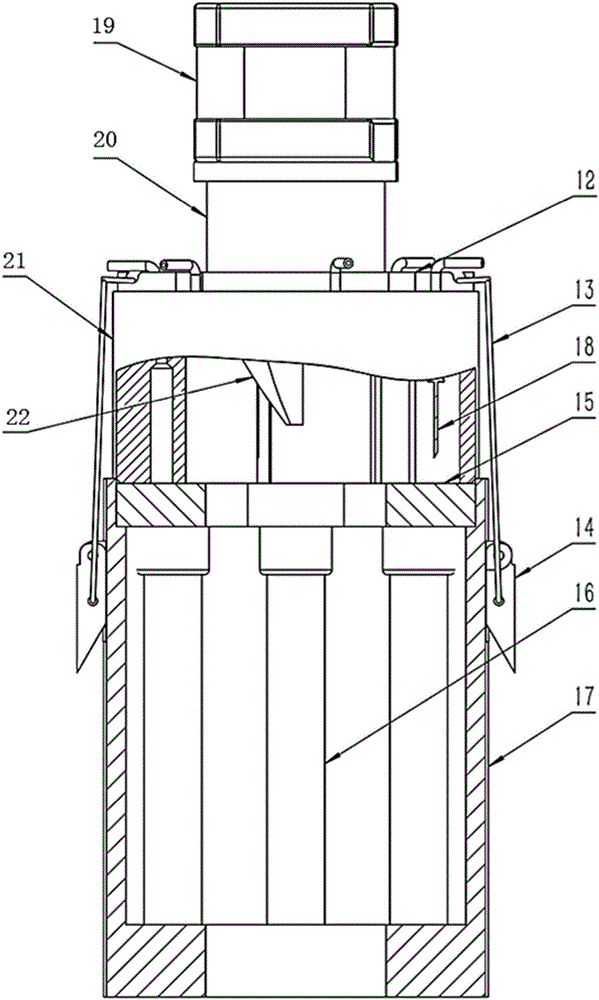

[0017] see Figure 1-2 The needle changing sampler of the present invention includes a first stepping motor 10 providing driving force, which is installed on the flange of the first flange seat 4 through screws, and the first outer ring with a cylindrical straight slideway slides Road 1 is installed on the round flange of the flange seat 4 through screws; the transmission shaft 5 is installed on the bearing seat of the flange seat 4 through the bearing 6, and one end is connected with the output shaft of the first stepping motor 10 through a set screw , the other end is connected with the first cylindrical cam 2. The first outer ring slideway 1 is installed concentrically with the first cylindrical cam 2 . The slider 8 and the cylindrical surface of the first outer ring slideway 1 form a low pair, and form a high pair with the first cylindrical cam 2; one e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com