Flyback converter

A converter and flyback technology, applied in the field of power conversion, can solve problems such as low conversion efficiency and high switching loss, and achieve the effect of high conversion efficiency and low switching loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

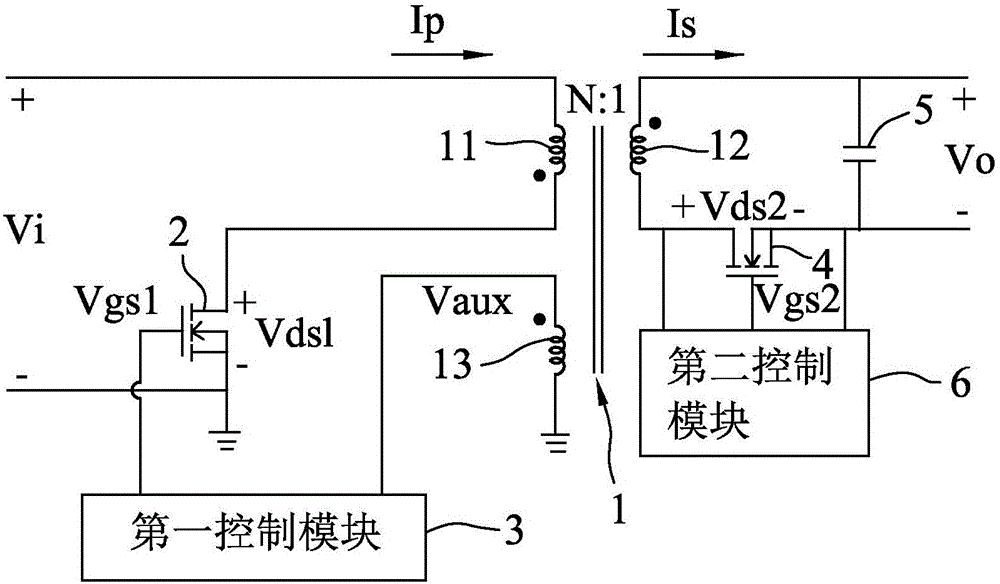

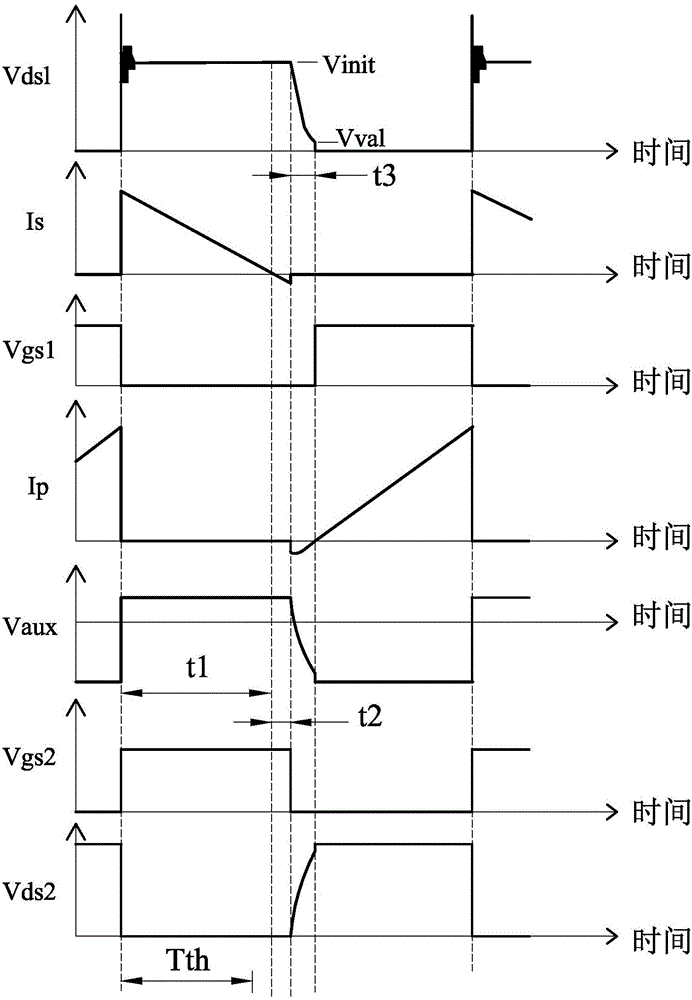

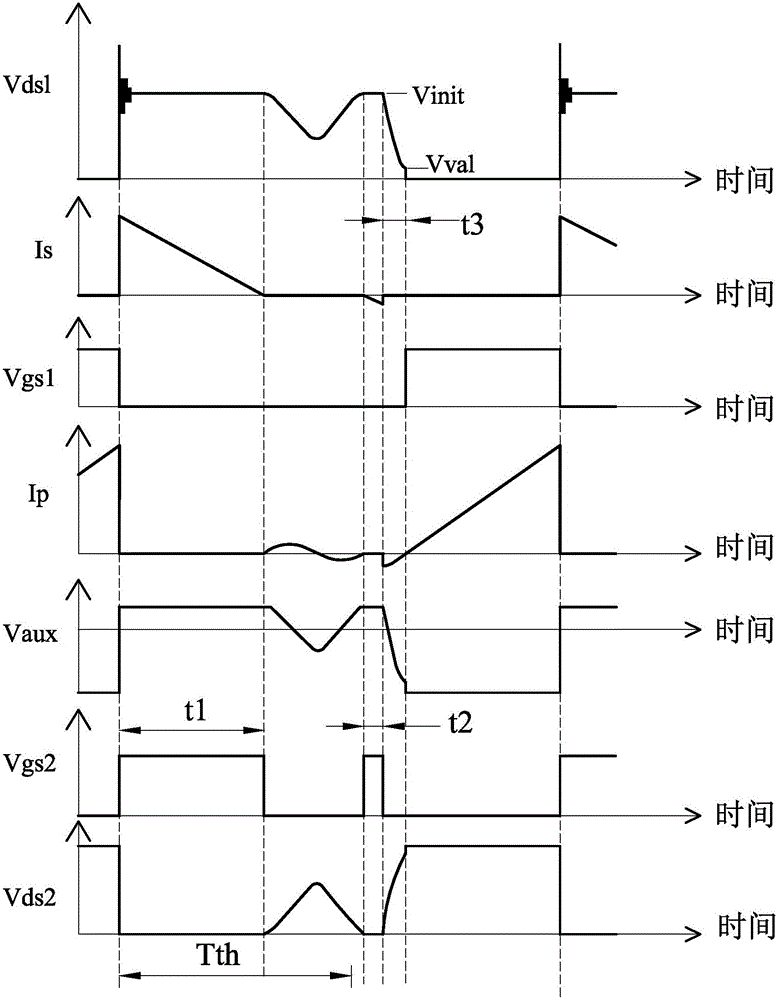

[0038] refer to Figure 1 to Figure 3 , an embodiment of the flyback converter of the present invention is suitable for converting an input voltage Vi into an output voltage Vo, and the flyback converter includes a transformer 1, a first switch 2, a first control module 3 , a second switch 4 , an output capacitor 5 and a second control module 6 .

[0039] The transformer 1 includes a primary winding 11 , a secondary winding 12 and an auxiliary winding 13 . Each of the primary, secondary and auxiliary windings 11, 12, 13 has a first end (eg, figure 1 a dotted end with a black dot shown) and a second end (e.g., figure 1 shown a non-dotted end without a black dot). The first ends of the primary, secondary and auxiliary windings 11, 12, 13 have the same voltage polarity. The number of turns of the primary winding 11 is N times that of the secondary winding 12 (that is, a turns ratio of the primary winding 11 and the secondary winding 12 is N), and the primary winding 11 receiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com