Endoscope cleaning and disinfection machine

A technology for cleaning and disinfecting endoscopes, applied in the direction of endoscopes, disinfection, telescopes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

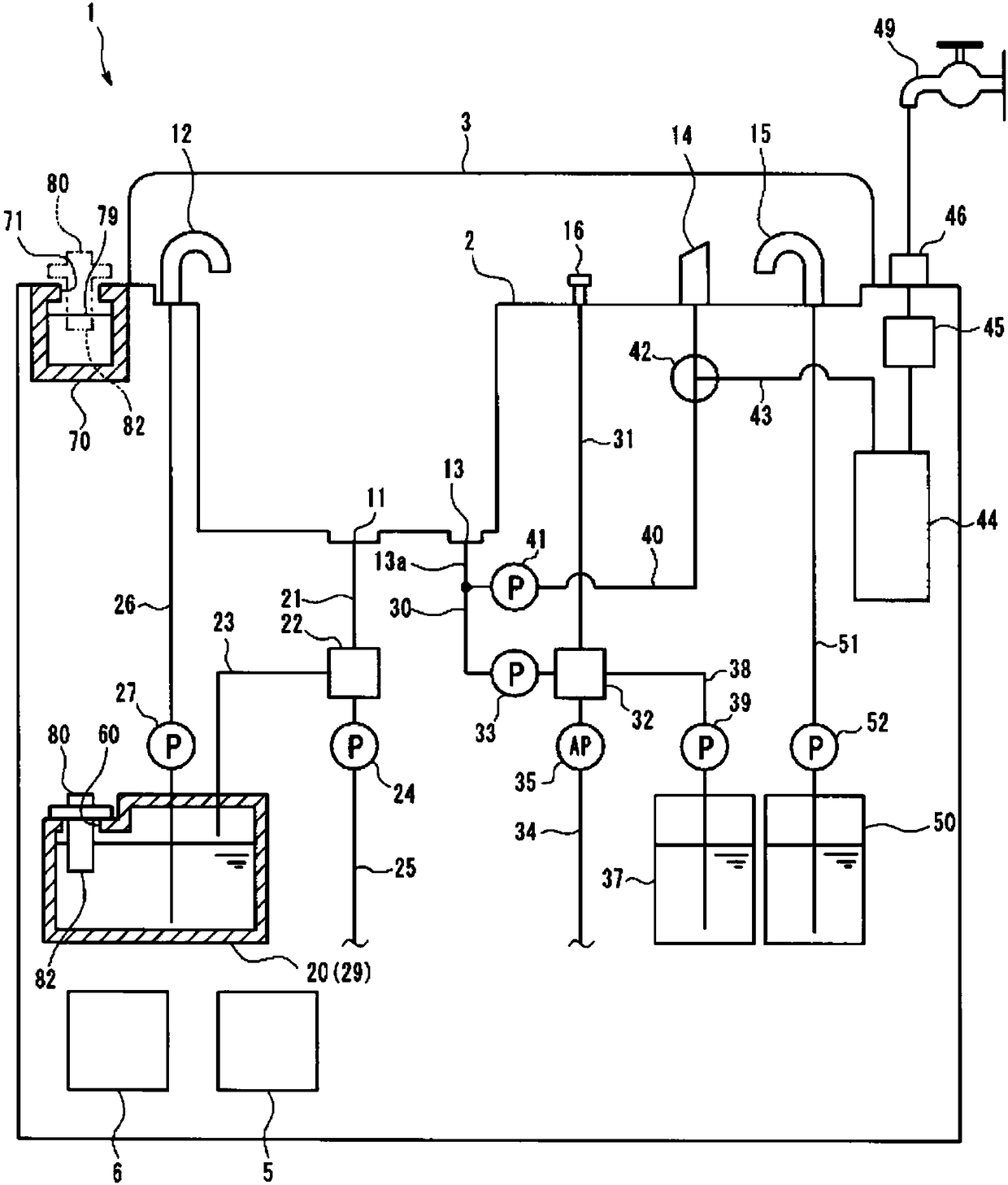

[0026] Hereinafter, an example of the embodiment of the present invention will be described. figure 1 The endoscope washer-disinfector 1 shown is a device for reusing an endoscope. The reuse treatment mentioned here is not particularly limited, and may be water-based rinsing treatment, cleaning treatment to remove dirt such as organic matter, disinfection treatment to inactivate predetermined microorganisms, sterilization treatment to eliminate or kill all microorganisms, and the above-mentioned treatments any of the combinations.

[0027] In addition, in the following description, upward means upward in the direction of gravity, and downward means downward in the direction of gravity. In addition, height in the following description shows the height relationship along the gravitational direction.

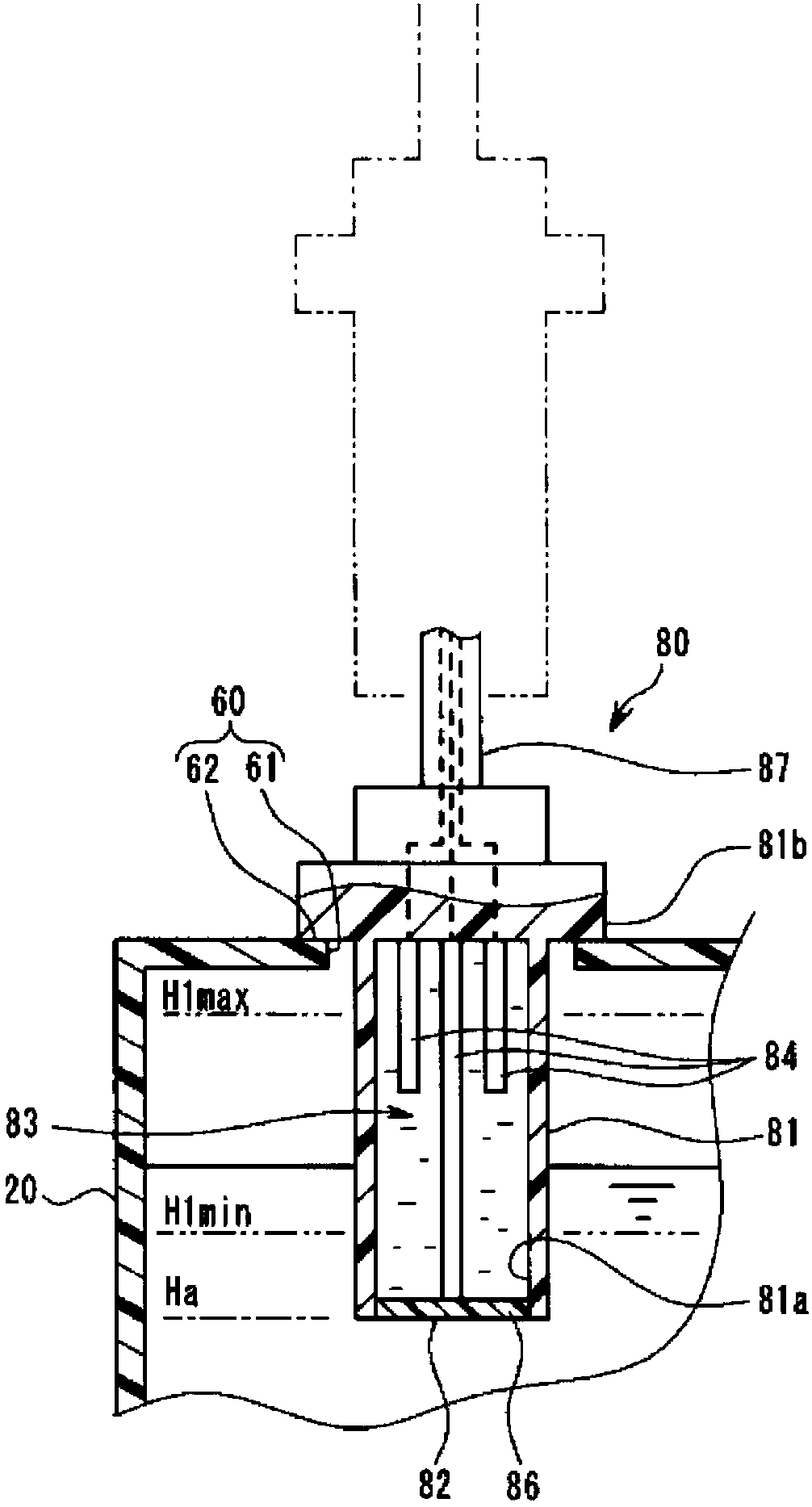

[0028] The endoscope washer-disinfector 1 includes a control unit 5 , a power supply unit 6 , a treatment tank 2 , a chemical solution container 20 , a first detachable unit 60 ...

no. 2 Embodiment approach

[0107] Next, a second embodiment of the present invention will be described. Hereinafter, only the points of difference from the first embodiment will be described, and the same reference numerals will be assigned to the same components as those in the first embodiment, and descriptions thereof will be appropriately omitted.

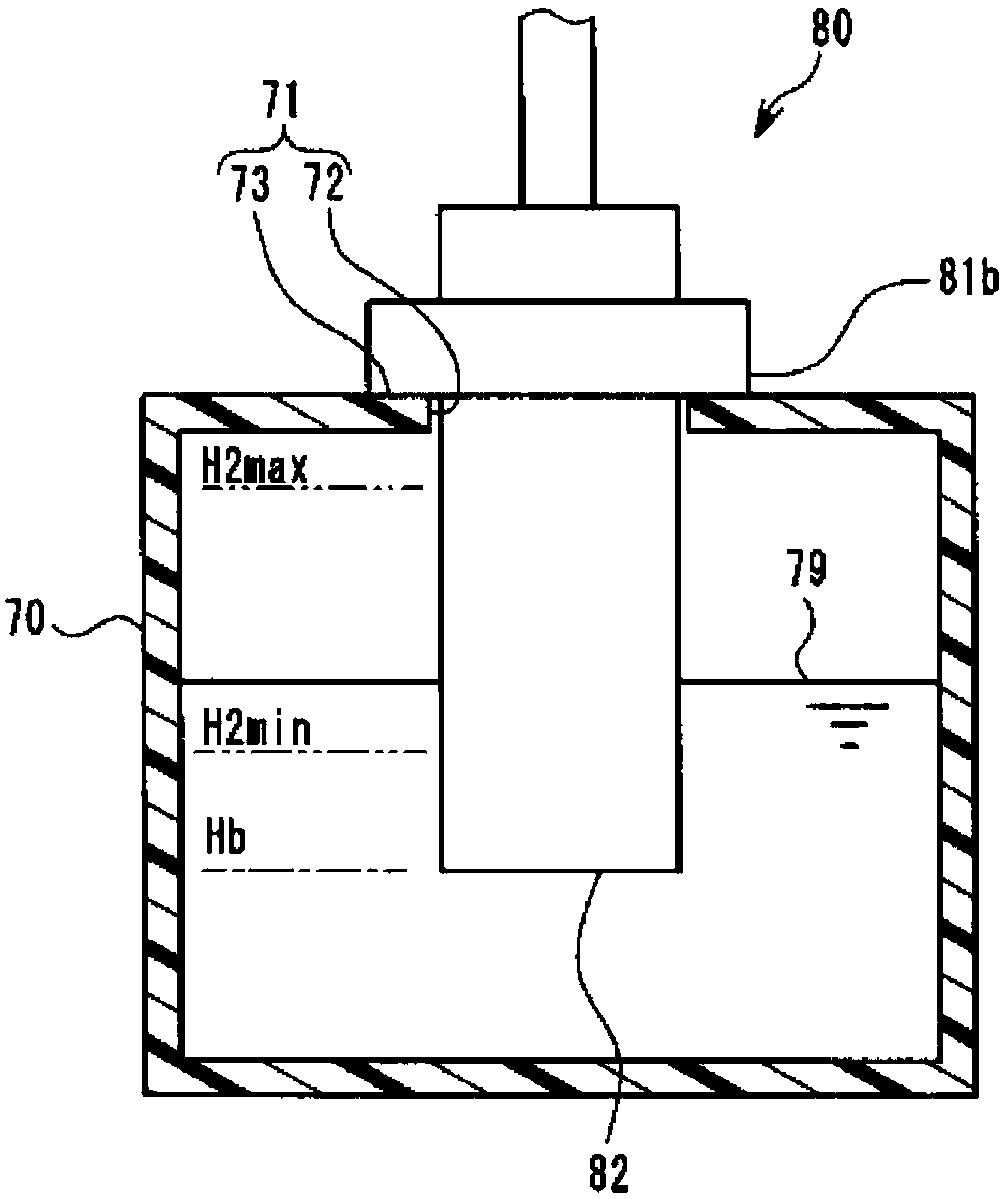

[0108] Figure 6 It is a figure which shows the schematic structure of the storage liquid container 70 of this embodiment. Such as Figure 6 As shown, the endoscope washer-disinfector 1 according to this embodiment includes a densitometer information reading unit 74 . The densitometer information reading unit 74 detects whether the second detachable unit 71 is holding the densitometer 80 , and outputs the detection result to the control unit 5 .

[0109]The structure of the densitometer information reading unit 74 is not particularly limited. For example, the densitometer information reading unit 74 may be a contact switch that changes output informa...

no. 3 Embodiment approach

[0114] Next, a third embodiment of the present invention will be described. Hereinafter, only the points of difference from the first and second embodiments will be described, and the same reference numerals will be assigned to the same components as those in the first and second embodiments, and descriptions thereof will be appropriately omitted.

[0115] Figure 7 It is a figure which shows the schematic structure of the storage liquid container 70 of this embodiment. Such as Figure 7 As shown, the endoscope washer-disinfector 1 according to this embodiment includes a temperature adjustment unit 75 that adjusts the temperature of the storage solution 79 so that the temperature falls within a predetermined temperature range.

[0116] The temperature adjustment unit 75 has any one of a configuration for heating the storage solution 79 , a configuration for cooling the storage solution 79 , and a combination of a configuration for heating the storage solution 79 and a config...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com