Water-free reverse osmosis water purifying machine

A technology of water purifier and reverse osmosis, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve waste of water, waste, increase the workload of preprocessors, etc. problems, to achieve the effect of prolonging the service life, avoiding installation and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

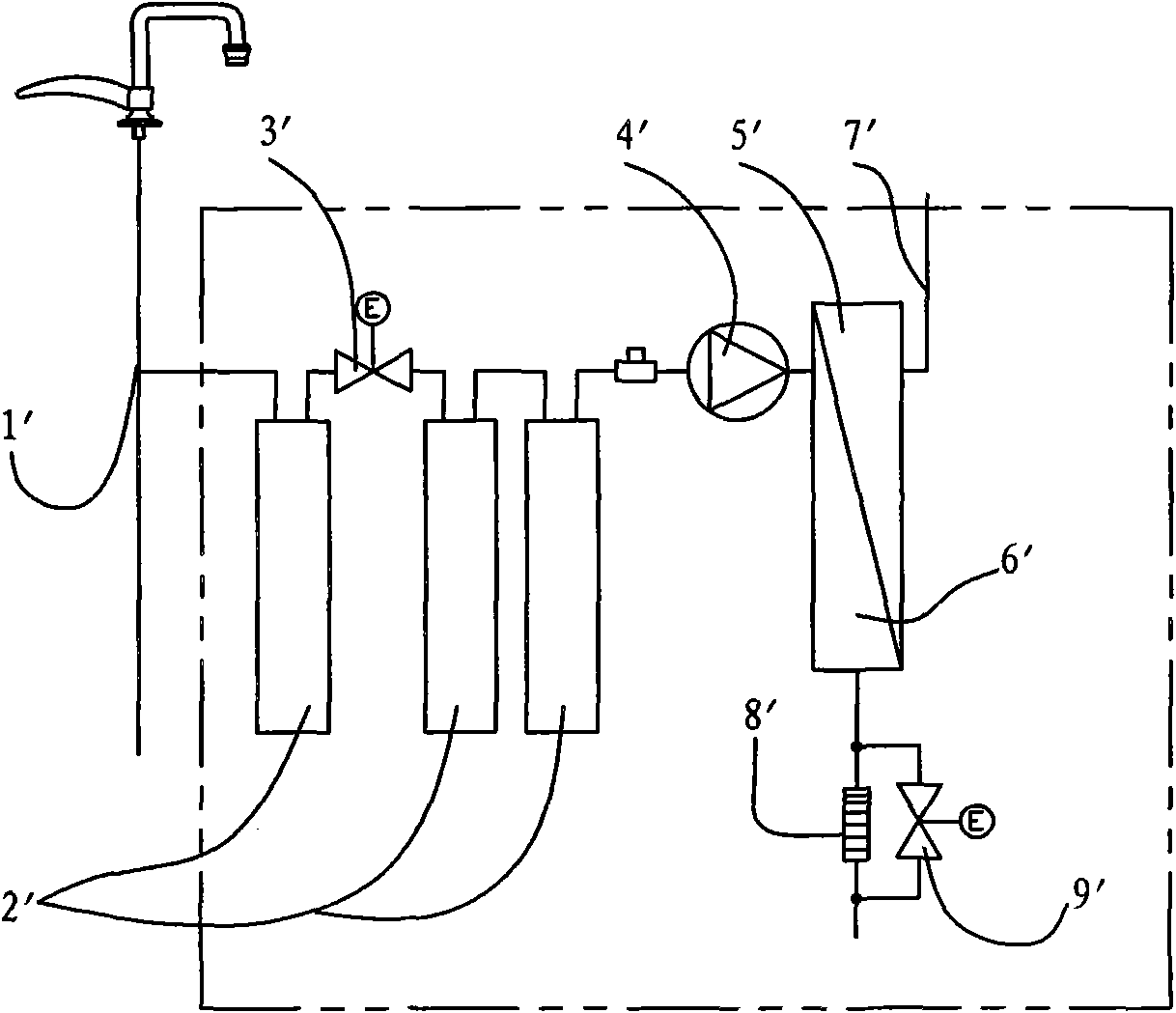

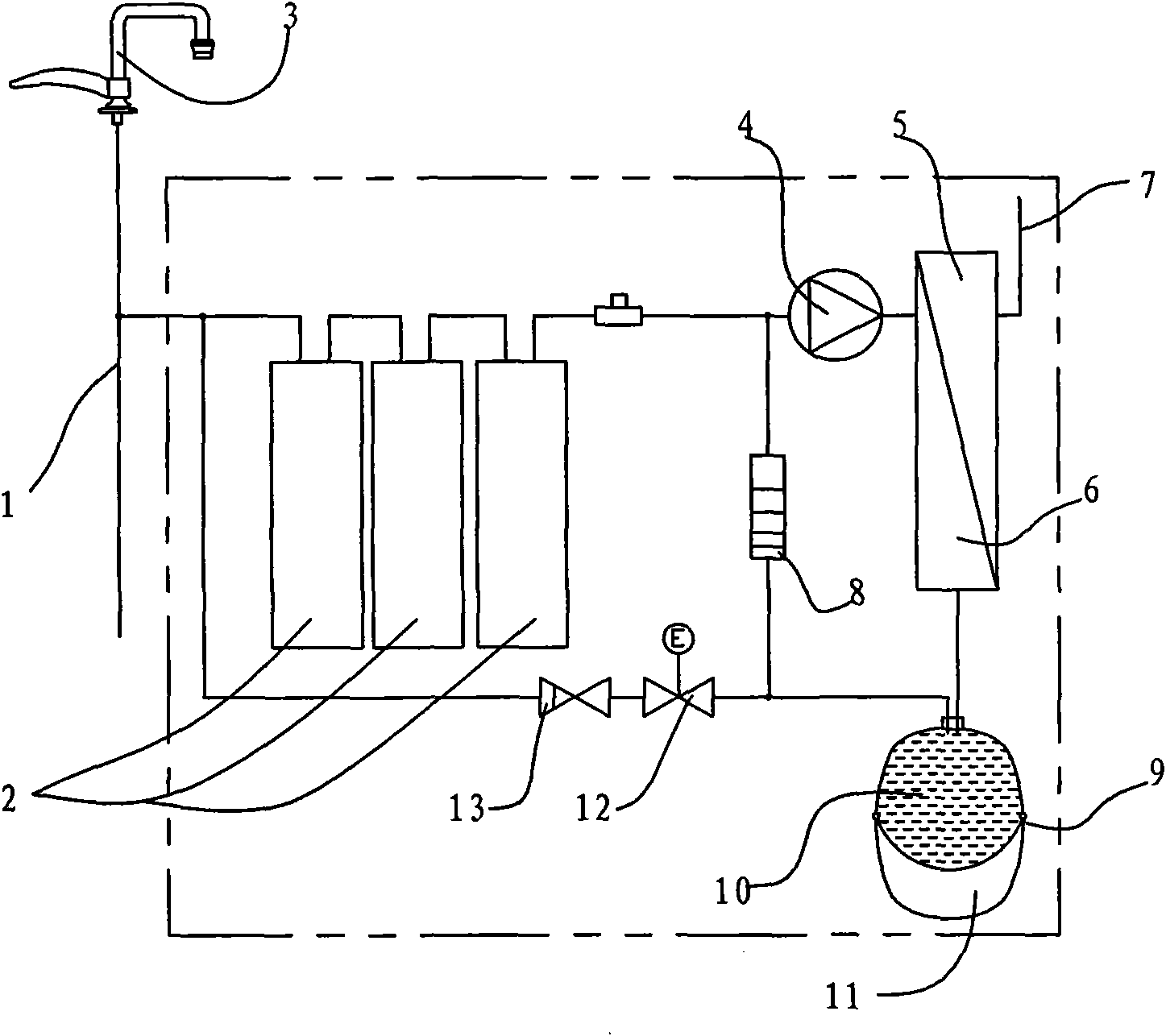

[0037] Such as figure 2 Shown, each part of the non-wastewater reverse osmosis water purifier of embodiment 1 can be connected in the following manner:

[0038]A water supply pipe 1 is connected to the source water pipe (with running water inside), and the water supply pipe 1 is connected in series with the preprocessor 2, the low pressure switch, the first booster pump 4 and the deep processor in series to form a water inlet channel, and the low pressure switch can prevent The water pump is dry without water and damages the water pump. Wherein the preprocessor 2 is composed of three pretreatment filter elements connected in series with each other. The deep processor is equipped with a reverse osmosis membrane module. The reverse osmosis membrane divides the deep processor into a pure water area 5 and a concentrated water area 6. The pure water area 5 is connected with the pure water outlet pipe for obtaining pure water. The inlet of the concentrated water area 6 is connect...

Embodiment 2

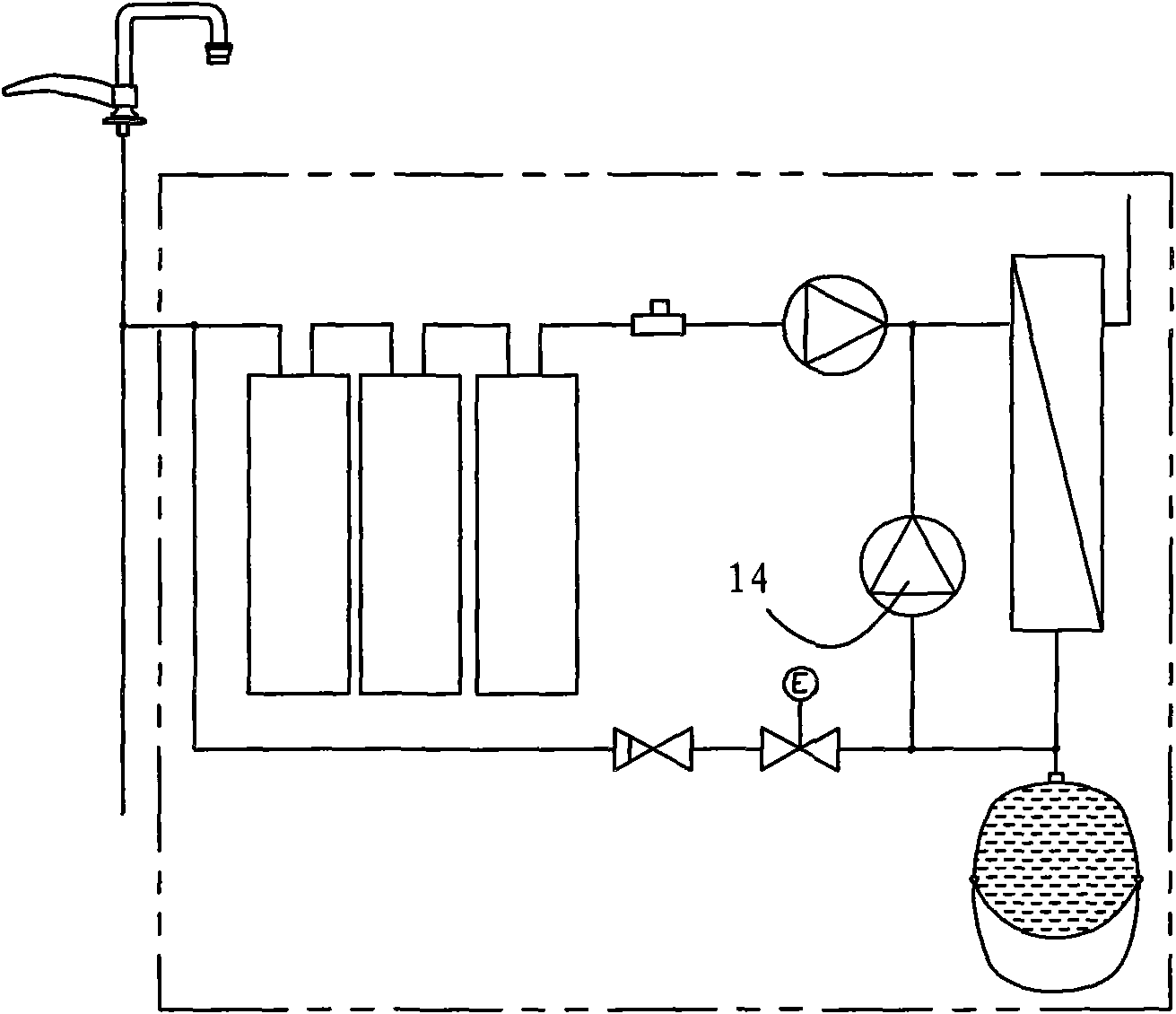

[0047] Such as image 3 As shown, the connection relationship of each part of the non-wastewater reverse osmosis water purifier of embodiment 2 is similar to embodiment 1, and the difference is that the waste water ratio 8 is replaced by the second booster pump 14, and the connection position is different, namely The inlet of the second booster pump 14 is connected to the water outlet of the water chamber 10 of the energy storage tank, and its outlet is connected to the outlet pipeline of the first booster pump 4 . Compared with Embodiment 1, the use of the second booster pump 14 can further increase the tangential flow of water flowing through the concentrated water side of the reverse osmosis membrane, and the flow is more stable.

Embodiment 3

[0050] Such as Figure 4 As shown, the difference from Embodiment 2 is that a pressure switch 15 and a second electric control valve 16 are connected in series at the water supply pipe and at the front end of the preprocessor, and the low pressure switch and the first booster valve set on the water inlet pipe in Embodiment 2 are cancelled. pump4.

[0051] In Embodiment 3, when water production is required, under the action of high water pressure, the pressure switch 15 is in a closed (or open) state, and the control system respectively turns on the second booster pump 14 according to the pressure switch signal and the required water production signal. 1. Open the second electric control valve 16 and close the first electric control valve 12, the source water passes through the second electric control valve 16 and the preprocessor in turn and enters the reverse osmosis filter element of the deep processor, and the pure water flows out from the outlet of the pure water area, Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com