Process damping of self-excited third octave mill vibration

A technology for rolling mills and rolling mill stands, which is applied in the field of vibration control in high-speed rolling mills, and can solve problems such as reducing the possible output of rolling mills, damage to metal strips, and slowing down the processing of rolled metal strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

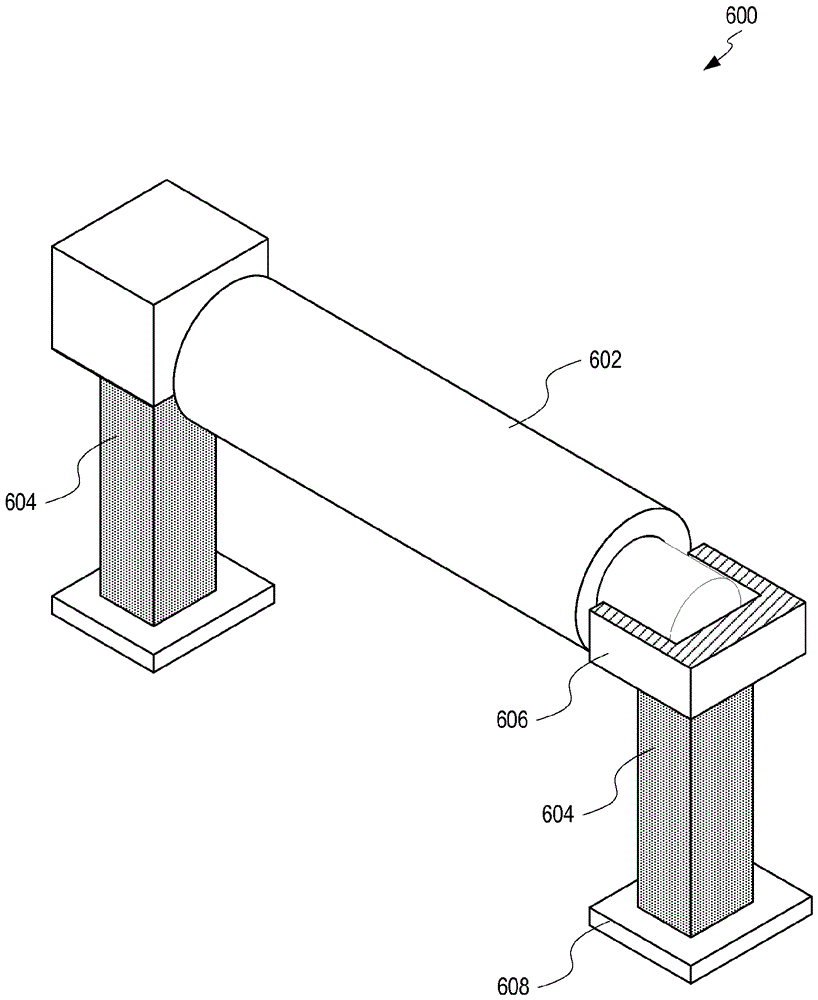

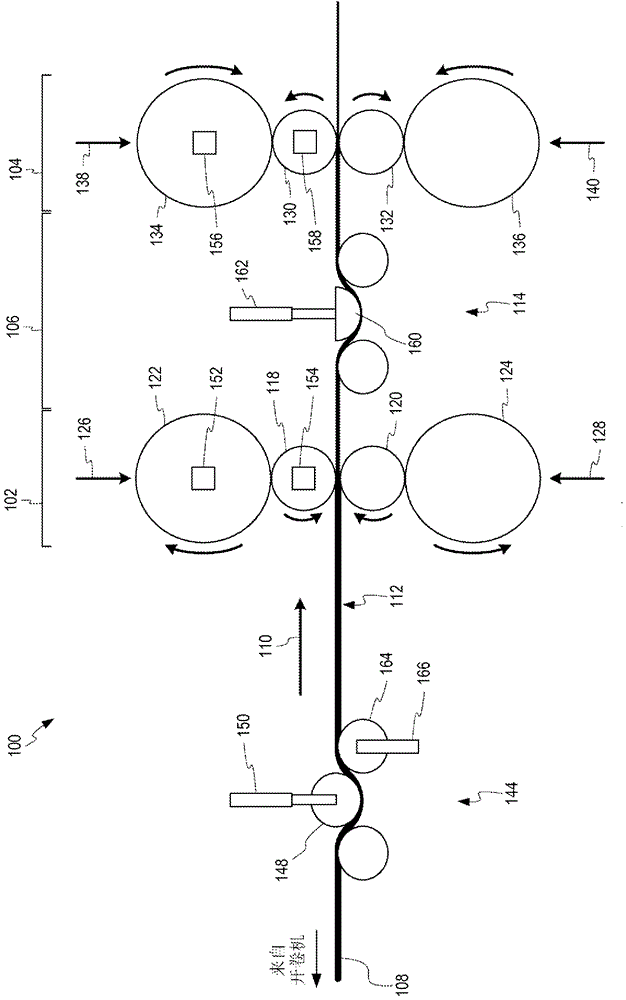

[0124] Example 1 is a tandem cold rolling mill of two (or more) stands comprising between the stands: a tensioning device selected from the group consisting of: center belt roll, actuated deflection roll or actuated foil scrapers; and a control system designed to vary the tensioning device in response to interstand strip tension disturbances occurring at the third octave mill stand resonant frequency typically in the range of approximately 90-300 Hz vertical placement.

example 2

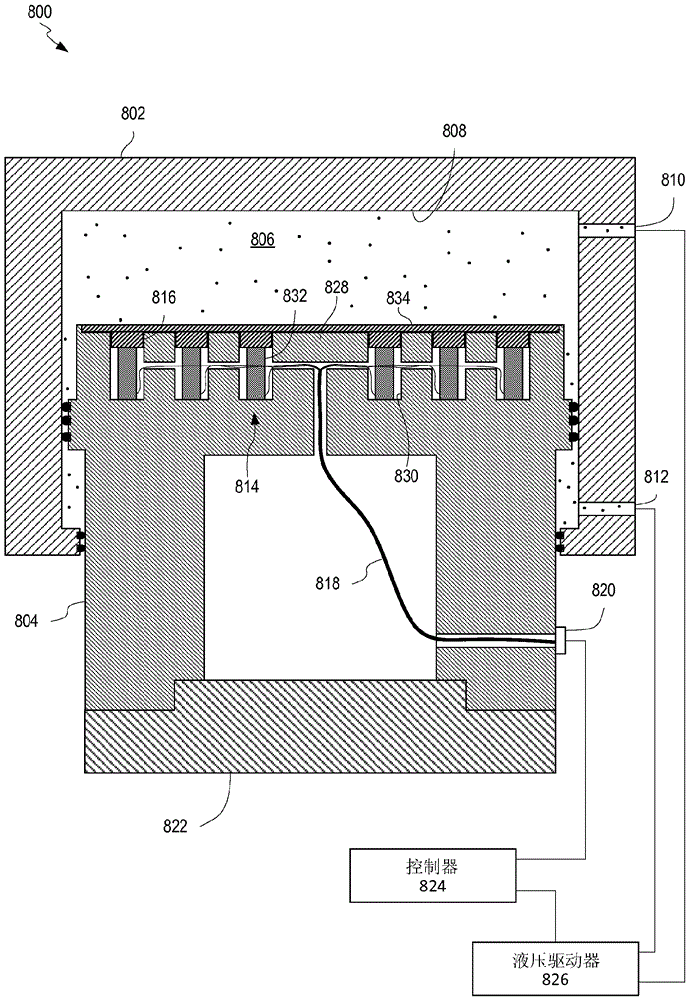

[0125] Example 2 is the rolling mill of Example 1, wherein the control system includes at least two hydraulic cylinders located near each end of the tensioning device, and a controller having a position control loop and a rapid tension loop, wherein the The fast tension loop is configured to change the vertical placement of the tensioning device in response to tension perturbations occurring at a third octave mill stand resonant frequency typically in the range of approximately 90-150 Hz, and the position control loop is controlled by Configured to maintain vertical placement of the tensioning device in response to tension disturbances occurring at lower frequencies.

example 3

[0126] Example 3 is the rolling mill of Example 1, wherein the control system includes at least two hydraulic cylinders positioned proximate each end of the tension adjustment device, each of the at least two hydraulic cylinders being positioned in contact with the tension adjustment device. multiple piezoelectric actuators between the devices, and a controller with a position control loop and a separate controller configured to respond to the Tension perturbations at the third octave mill stand resonant frequency change vertical placement of the tensioning device, and the position control loop is configured to maintain the tensioning device in response to tension disturbances occurring at lower frequencies Place vertically.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com