Novel vertical corn thresher

A vertical, thresher technology, used in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of reducing the practical life of the equipment, overloading the operation of the equipment, and high working costs, to improve the service life of the equipment, reduce the threshing cycle, The effect of improving operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

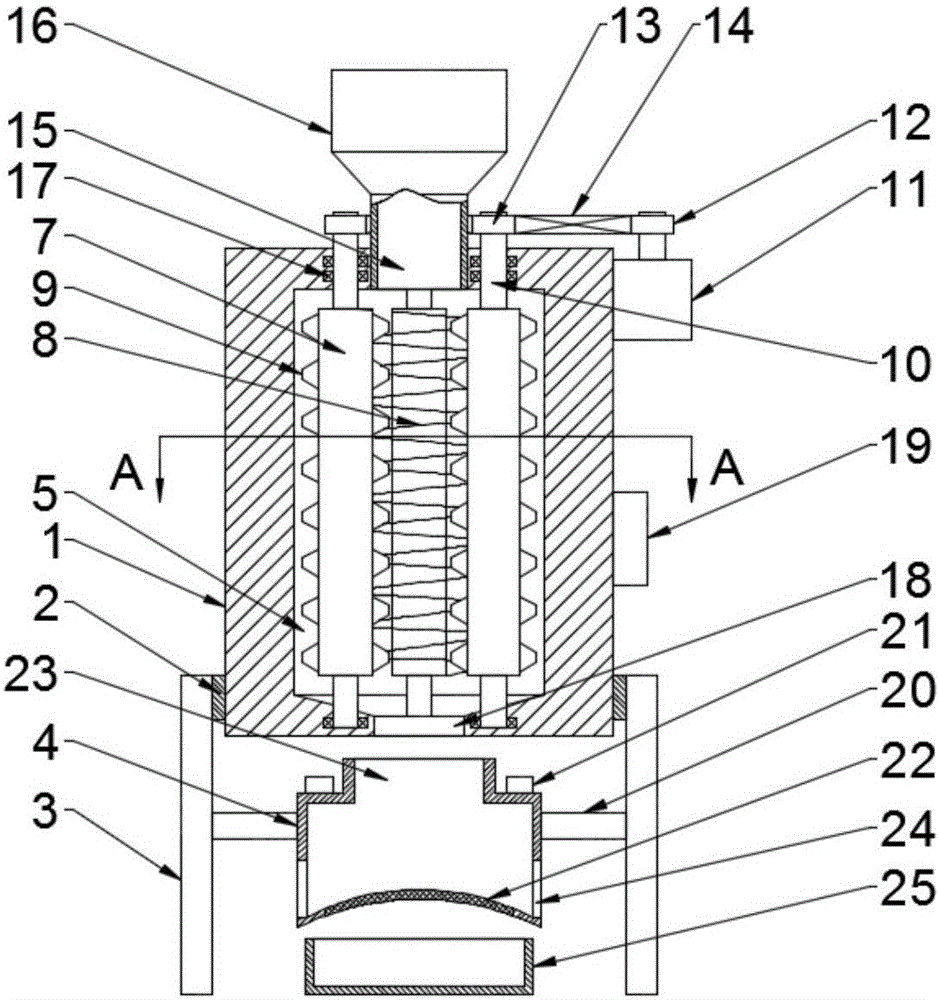

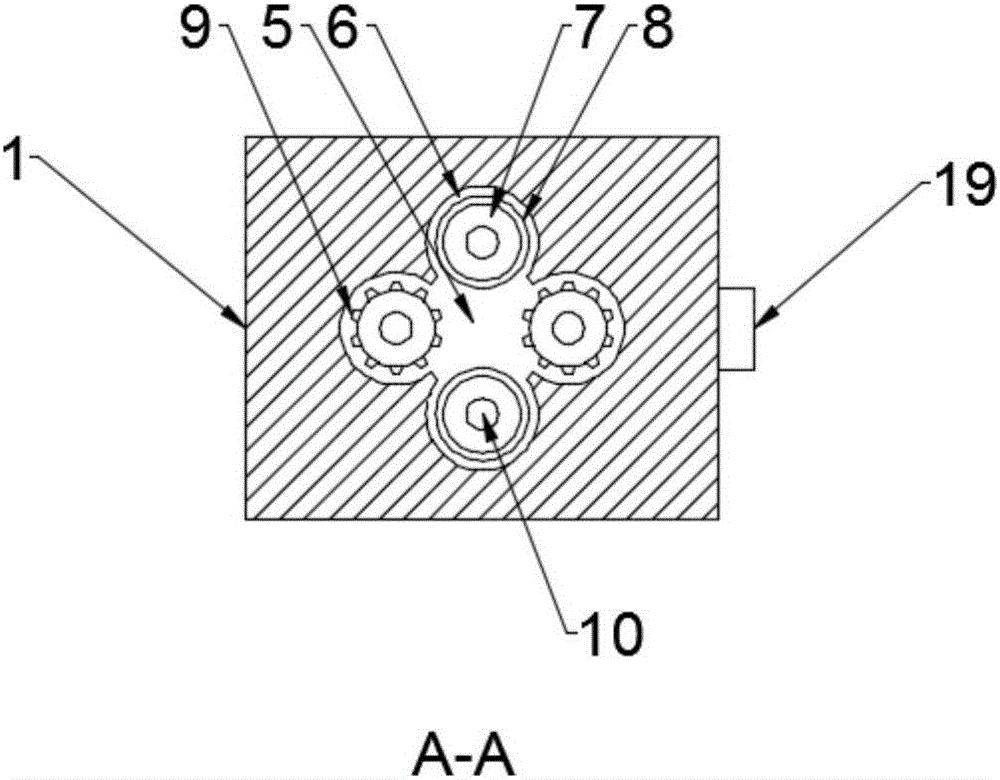

[0021] see Figure 1~2 , a new type of vertical corn thresher, comprising a body 1, the bottom end of the outer surface of the body 1 is provided with a fixed frame 2, and a plurality of legs 3 are uniformly arranged on the fixed frame 2, and the inside of the body 1 A main threshing chamber 5 and four auxiliary threshing chambers 6 are provided, and the four auxiliary threshing chambers 6 are evenly distributed around the main threshing chamber 5, and the main threshing chambers 5 are interlacedly connected with the four auxiliary threshing chambers 6 respectively, Both the main threshing chamber 5 and the auxiliary threshing chamber 6 are cylindrical chamber structures, and the four auxiliary threshing chambers 6 are provided with threshing rollers 7, and the threshing rollers 7 are connected with the body 1 through a rotating shaft 10, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com