Tomato bracket

A tomato and support rod technology, applied in the field of tomato racks, can solve the problems of low work efficiency, easy to fall off straps, increased labor intensity, etc., and achieve the effects of improving work efficiency, convenient removal, labor saving, and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

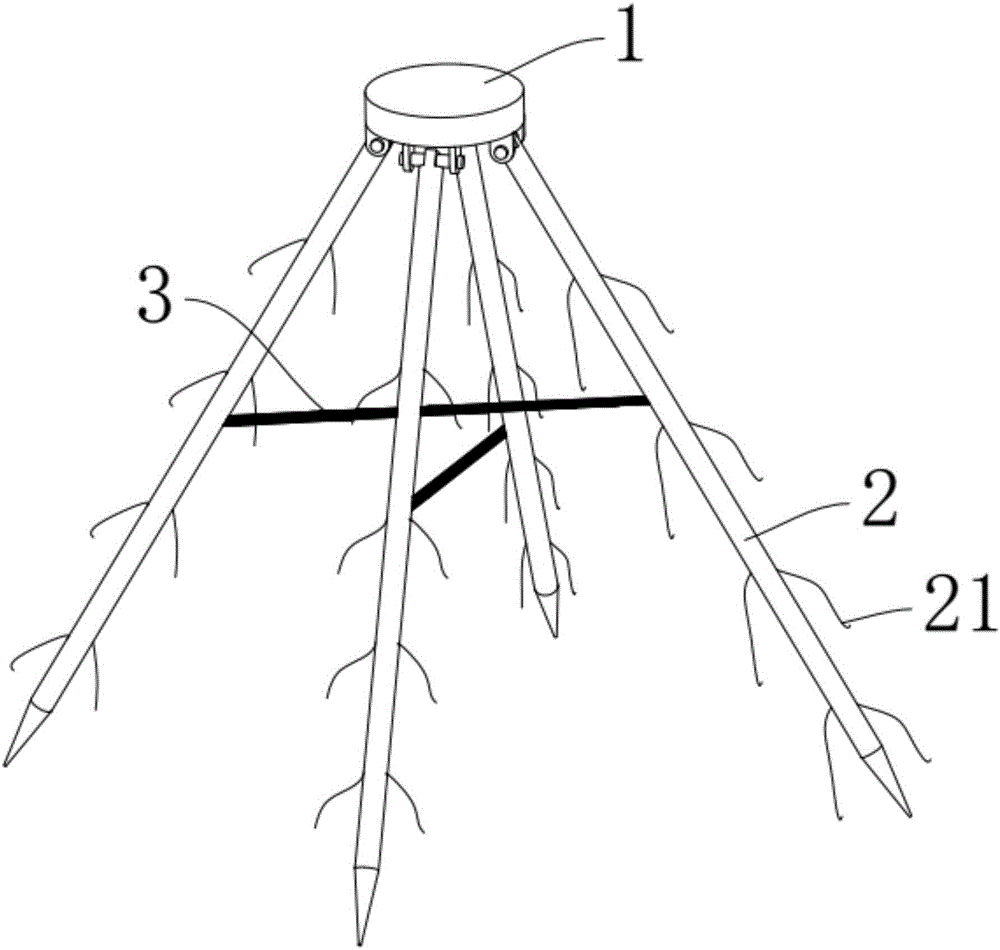

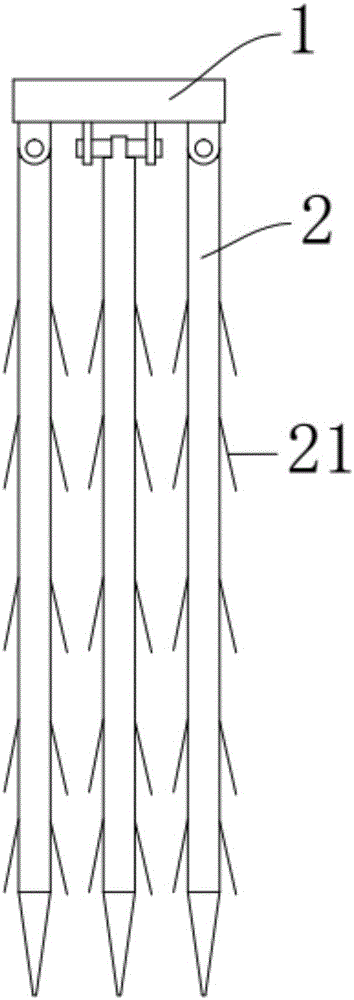

[0015] The tomato rack of the present invention comprises a support base 1, connecting pins, and four support rods 2. Four hinge supports are arranged on the bottom surface of the support base 1, and the upper ends of the support rods 2 are hinged with the hinge supports through the connection pins. Rotate relative to the connecting pin; when the four support rods 2 are respectively inclined relative to the horizontal plane, such as figure 1 As shown, the support base 1 and the four support rods 2 form a quadrangular pyramid; the lower ends of the support rods 2 are pointed, and several groups of straps 21 are arranged on the support rods 2 at equal intervals.

[0016] Preferably, the support rod 2 is a telescopic rod. The telescopic rod is a commonly used technical means in the prior art. The benefit of using the telescopic rod in the present invention is that it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com