Power-driven hydraulic straightener for ring lock scaffold

The technology of straightening machine and disc buckle is applied in the field of electric hydraulic straightening machine of disc buckle frame, which can solve the problems such as the inability to adjust the speed of the hydraulic cylinder, the inability to adjust the speed of the oil cylinder, the inconvenience of clamping the disc buckle frame, etc., and the appearance is beautiful. , the effect of convenient operation and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

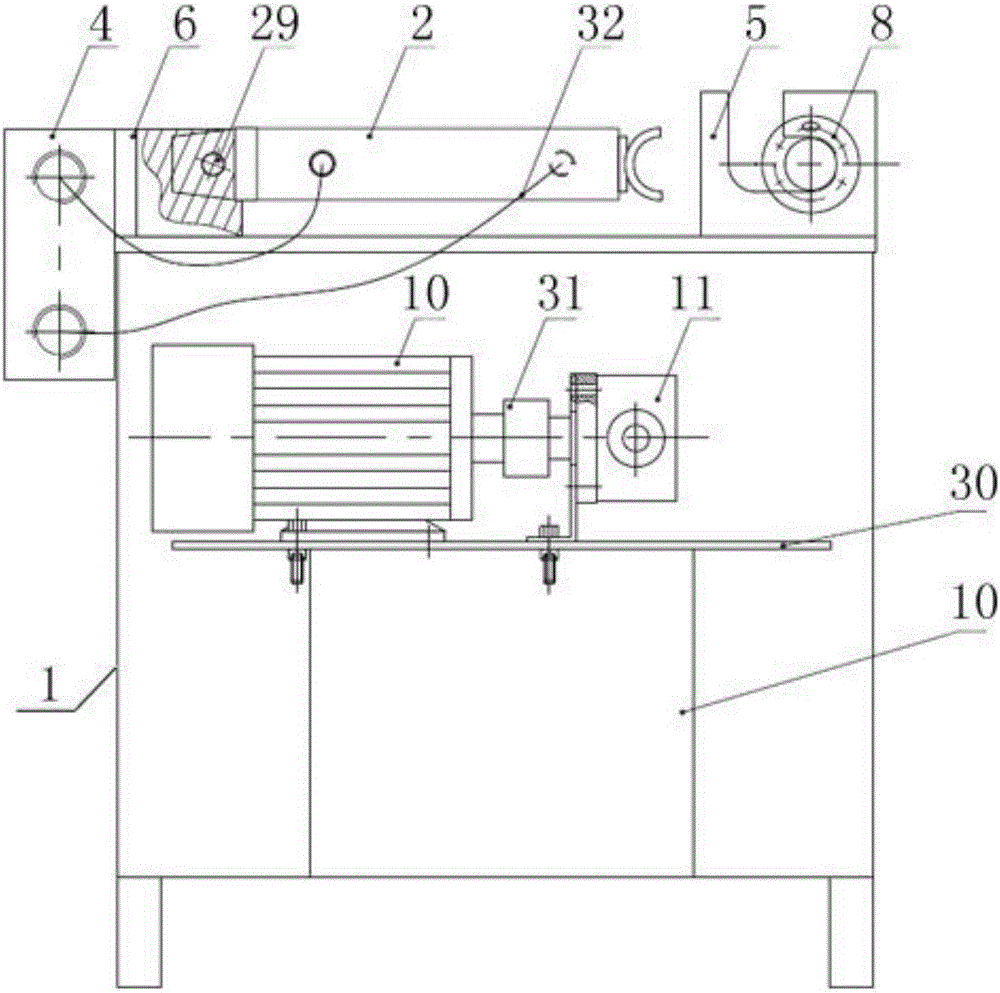

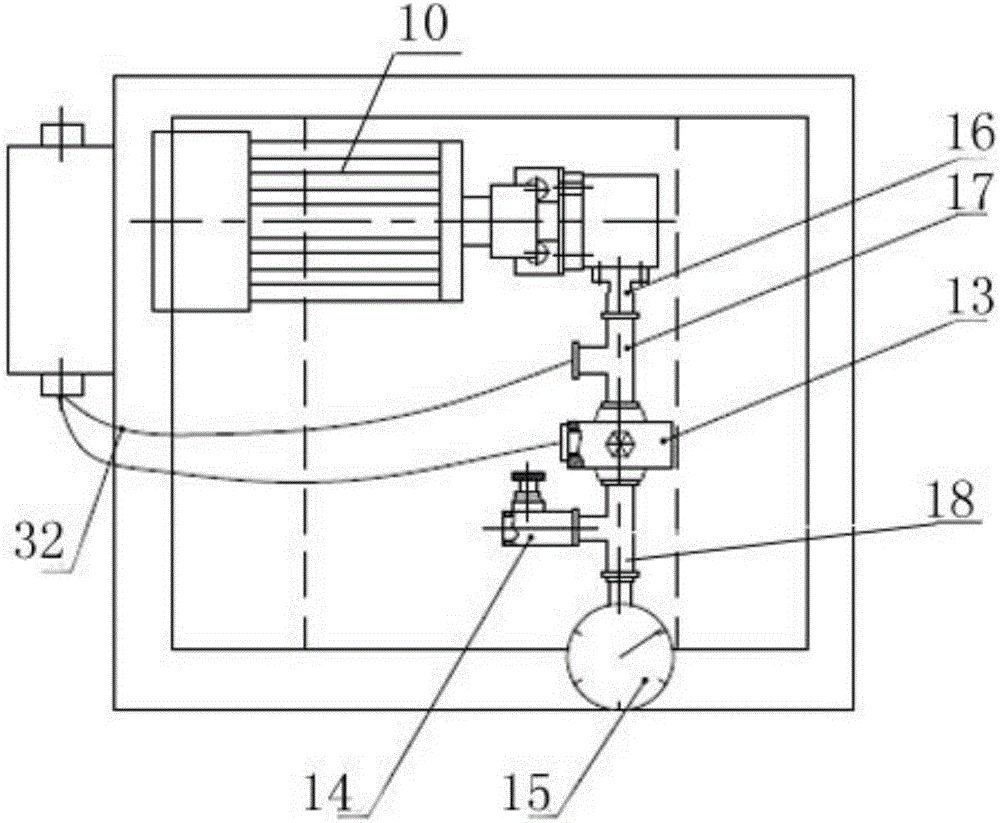

[0025] Such as Figure 1-2 As shown, an electro-hydraulic straightening machine for a coil frame of the present invention includes a straightening machine casing 1, a hydraulic cylinder 2, a hydraulic station 3, a steering valve 4, and a clamping platform 5 for a coil frame, and the coil frame 8 includes a support pipe 28 and disc buckle 25, generally a supporting pipe 28 is evenly welded with 2-4 disc buckles 25, and the straightening machine box body 1 adopts angle steel welding to form a frame type; a panel is placed on the frame, and an oil cylinder fixing plate is welded on the panel to fix the parts plate.

[0026] The hydraulic cylinder 2 is arranged on the upper side of the straightening machine casing 1 through the cylinder fixing assembly 6, the cylinder seat of the hydraulic cylinder 2 is installed on the cylinder fixing assembly 6 through the pin shaft 29, and the front end of the cylinder push rod 7 of the hydraulic cylinder 2 is provided with a useful For the st...

Embodiment 2

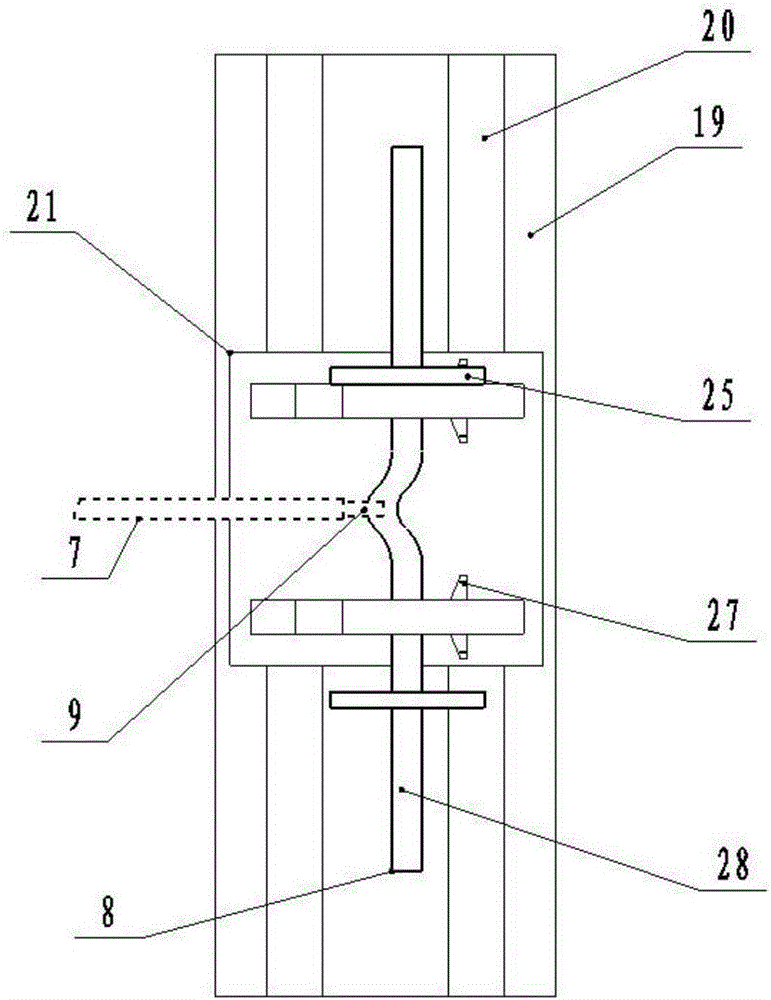

[0032] Such as Figure 3-4 As shown, the present invention is an electro-hydraulic straightening machine for coil racks. On the basis of Embodiment 1, the clamping table 5 for coil racks includes a fixed platform 19, a guide rail 20 and a moving frame for clamping the coil racks 8 21. The lower part of the fixed table 19 is fixed on the straightening machine box 1 by welding or bolts. The fixed table 19 is provided with two parallel guide rails 20. The guide rails 20 adopt an I-shaped shape, which is convenient for clamping the mobile frame 21 and the mobile frame. 21 is arranged on guide rail 19 and slides. The mobile frame 21 includes a chute platform 22 and a buckle frame clamping plate 23 for cooperating with the guide rail 19. The chute platform 22 is installed on the guide rail 19 to adjust and slide, and two parallel pan buckles are arranged on the chute platform 22. Frame clamping mounting plate 23, on which there is an L-shaped clamping slot 24 for clamping the disc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com