Pneumatic clamping device used for welding bolt on flange

A flange welding and pneumatic clamping technology, used in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of inability to effectively prevent dislocation, unreliable clamping effect, and low tightening efficiency, saving waiting time, clamping Good tightening effect and fast clamping action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

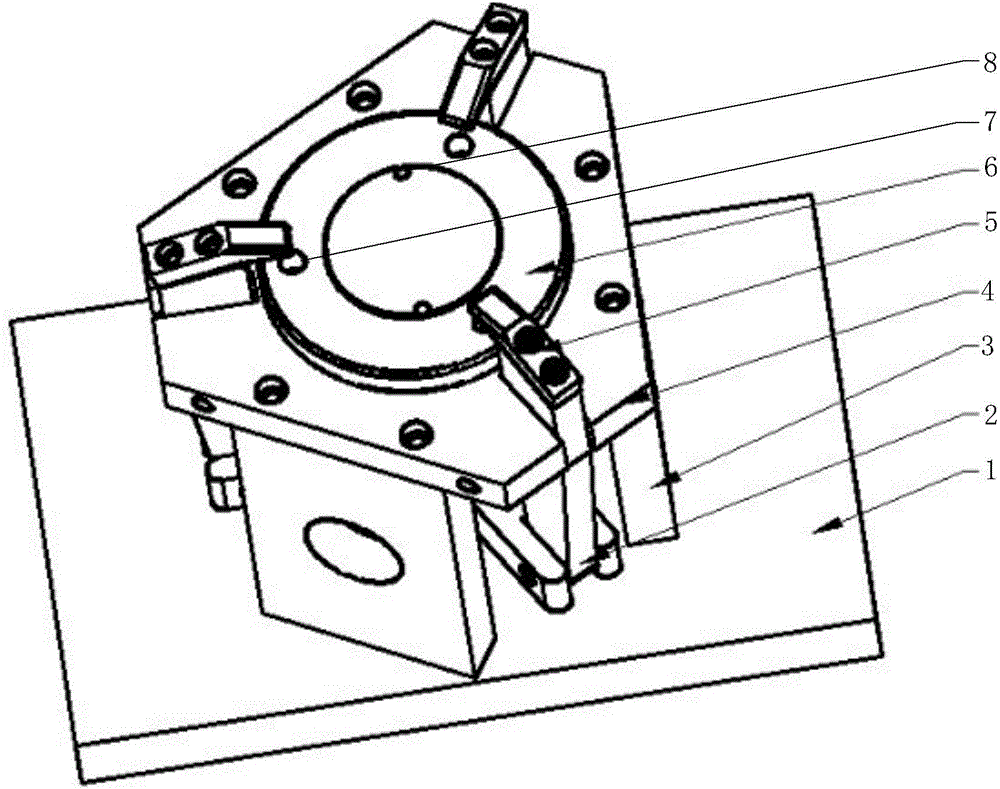

[0017] During specific implementation, combined with figure 1 , a pneumatic clamping device for flange welding bolts, including a base 1, a cylinder connecting rod seat 2, a vertical load-bearing column 3, a connecting rod base 4, jaws 5, and a flange placing chassis 6. The upright load-bearing base 3 is fixed on the base 1, and the upright load-bearing base 3 can be fixed on the base 1 by bolts. The connecting rod base 4 is installed on the vertical bearing base 3, and the connecting rod base 4 can be fixed on the vertical bearing base 3 by bolts. The flange placing chassis 6 is placed on the connecting rod base 4, and the flange placing chassis 6 can be fixed on the connecting rod base 4 by bolts. The cylinder connecting rod seat 2 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com