Force expansion type dual-template mould clamping mechanism using four boosting cylinders

A technology of pressurized cylinder and double template is applied in the field of four-pressurized cylinder expansion type dual template clamping mechanism, which can solve the problems of unstable operation and large quality, and achieve fast clamping action, weight reduction, and clamping mechanism. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

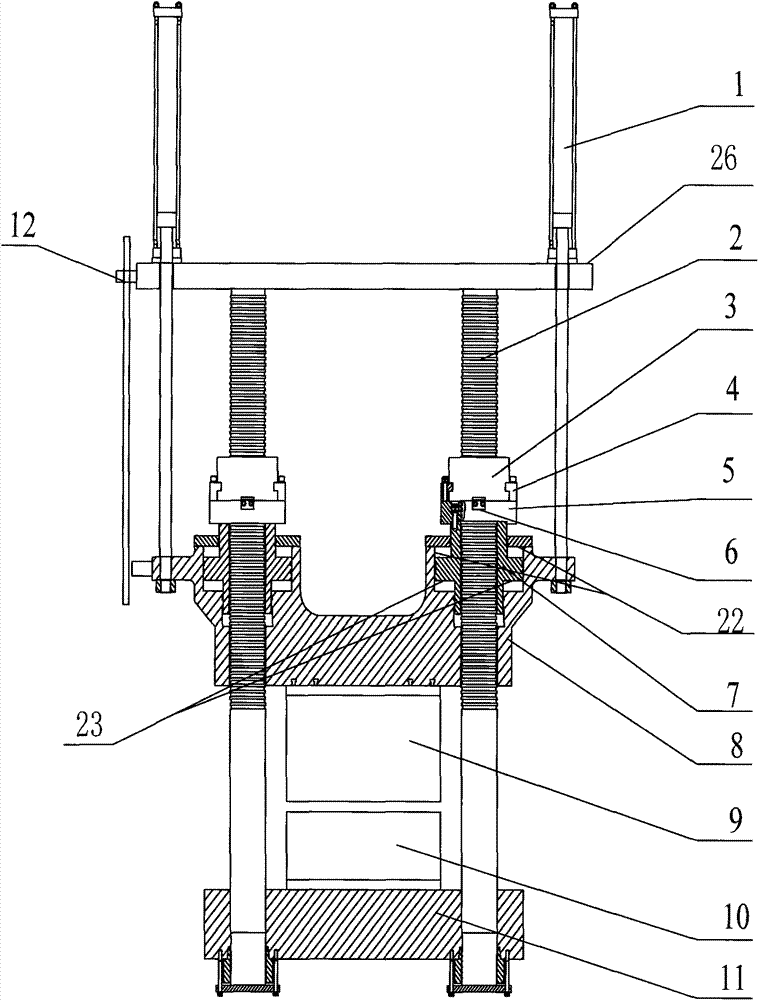

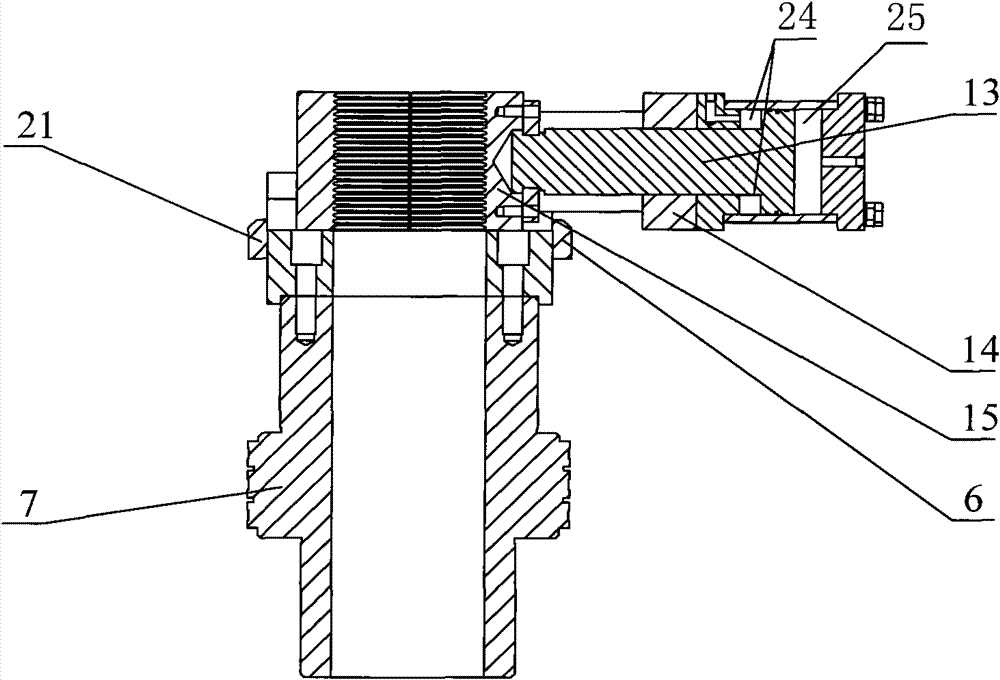

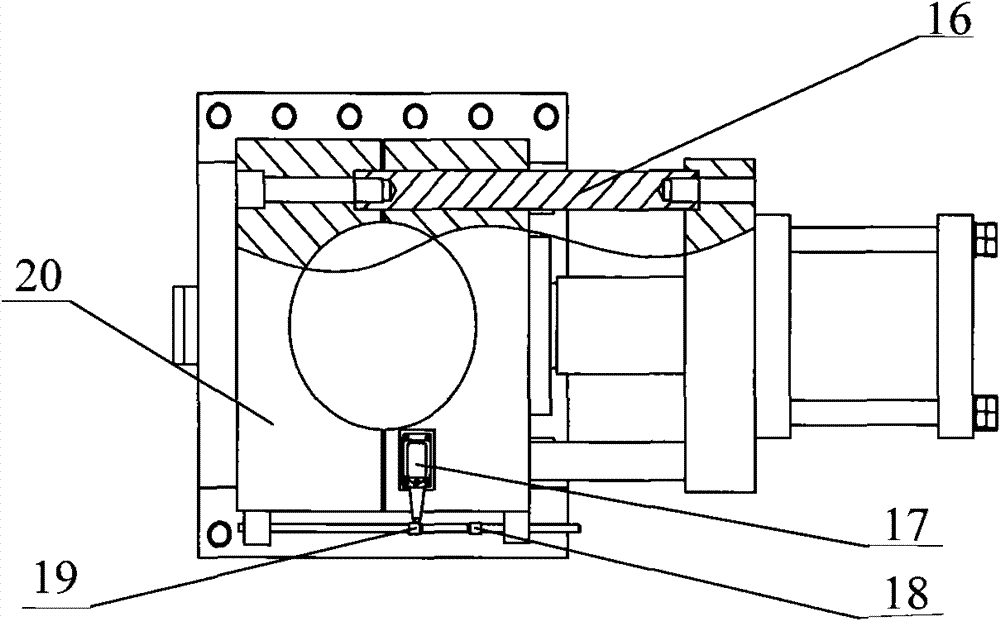

[0018] like figure 1 , 2a , 2b, four pressurized cylinder expansion force type double template clamping mechanism, mold clamping cylinder base 26, big bar 2, head plate 11, two closing cylinders on the mold clamping cylinder base 26 relative to the left and right sides of big bar 2 are housed Die oil cylinder 1, head plate 11 is connected with fixed mold 10, mold clamping oil cylinder 1 is driven and connected with movable seat plate 8, movable seat plate 8 is connected with movable mold 9, and mold clamping cylinder piston 7 is installed on movable mold seat plate 8, and mold clamping The cylinder piston divides the clamping cylinder into two cylinders, which are the first group of pressurized cylinders 22 and the second group of pressurized cylinders 23. The clamping cylinder piston 7 is equipped with a nut mounting seat plate 5, and the nut mounting seat plate 5 A split nut 3 is housed above the split nut 3, and the split nut 20 of the left half of the split nut 3 is drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com