Super-fireproof door leaf

A fire-resistant door leaf and fire door leaf technology, applied in the field of fire doors, can solve the problems of poor heat insulation effect, insufficient fire resistance performance, and heavy fire door leaf weight, etc., and achieve the effect of good fire resistance performance, light weight, and enhanced heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

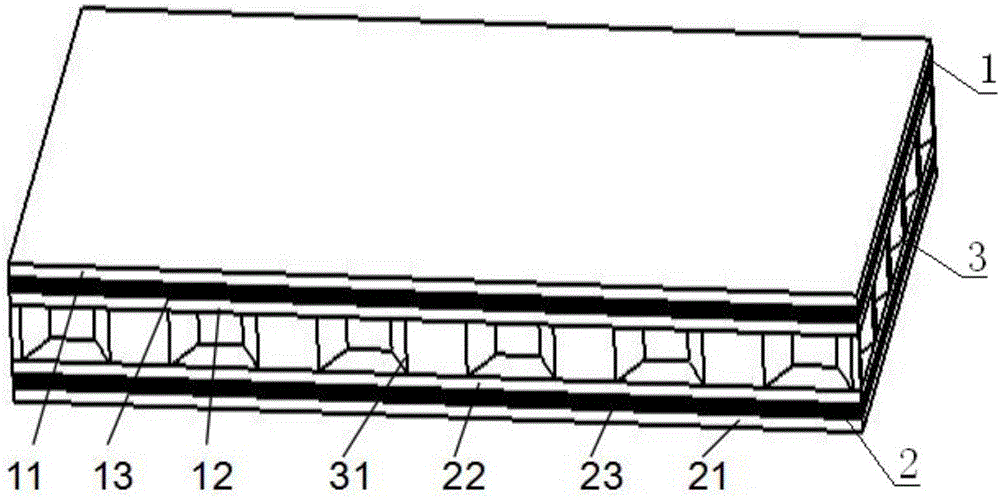

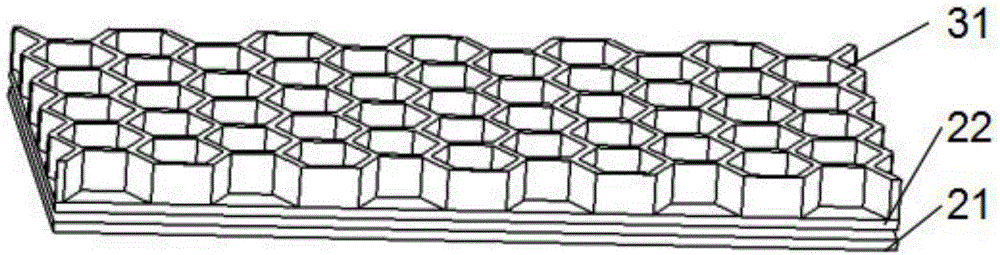

[0020] Such as figure 1 , 4 As shown, the super fire-resistant door leaf of the present invention includes a front panel 1, a rear panel 2 and a core plate 3 placed between the front panel 1 and the rear panel 2, and the front panel 1 or / and the rear panel 2 are vacuum Airtight cavity.

[0021] At least one panel is a vacuum-tight cavity, which is beneficial to heat insulation and reduces the weight of the panel.

[0022] As an example, the rear panel 2 and the front panel 1 of the vacuum-tight cavity are formed in this way.

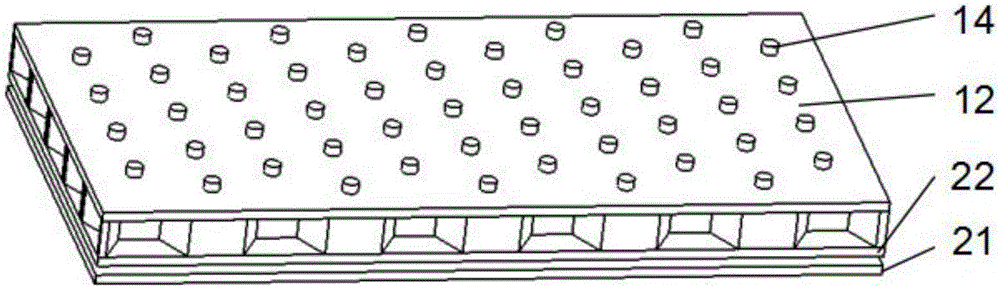

[0023] The rear panel 2 includes an outer plate 21, an inner plate 22, a peripheral frame 23 and a plurality of support columns 24 supported between the outer plate 21 and the inner plate 22, the peripheral frame 23 and the outer plate 21 , The inner layer board 22 is airtightly connected and vacuumized.

[0024] The front panel 1 includes an outer plate 11, an inner plate 12, a peripheral frame 13 and a plurality of support columns 14 supported betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com