State switching method and device for N-nails

A state transition and state technology, applied in packaging and other directions, can solve the problems of slow production rate and a lot of manpower, and achieve the effect of speeding up production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention provides a kind of method of N nail overturning:

[0018] Install a protruding object on the side of the track. When the N nail passes by, it hits the protrusion, causing the N nail to fall due to the offset of the center of gravity, and the N nail changes from an upright state to a flat state.

[0019] In order to achieve the above method, a device can be used:

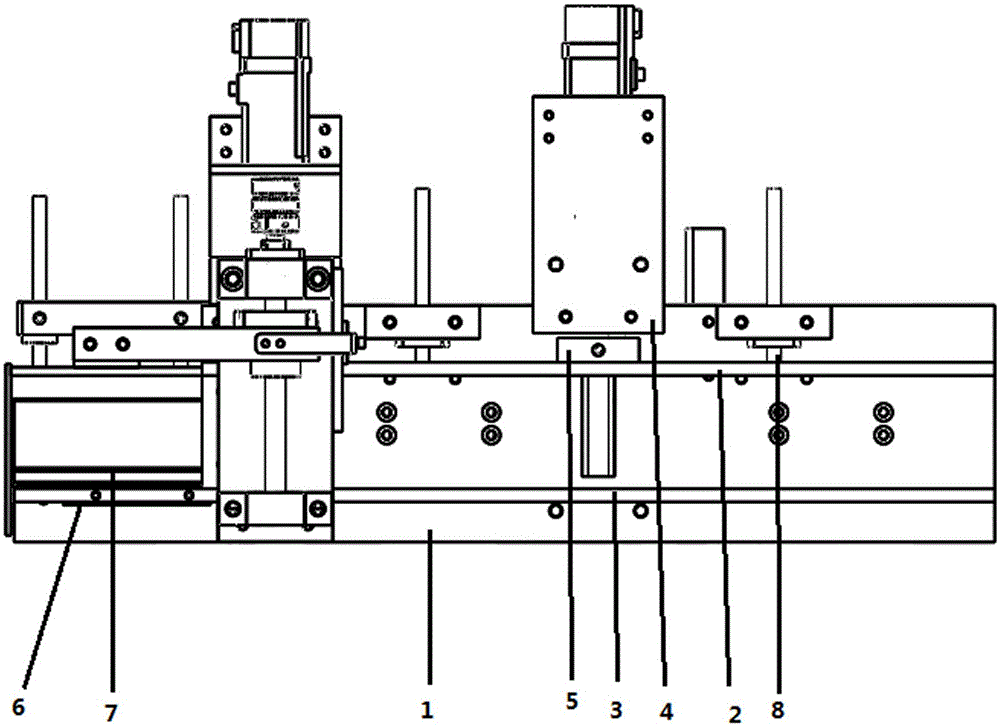

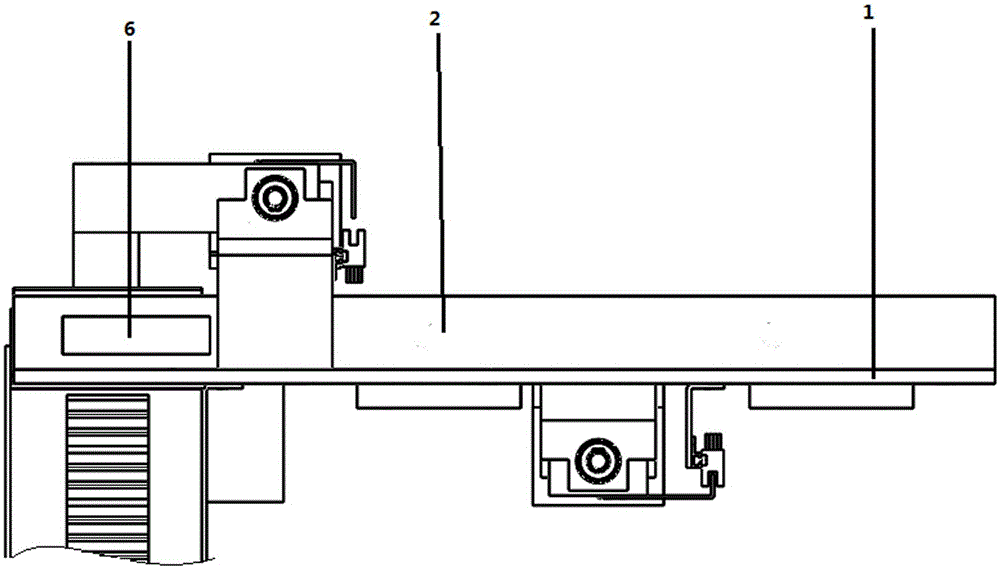

[0020] At the outlet of the N nails, connect the conveying plate 1, and install baffles on both sides of the conveying plate 1 to form a track. The baffle 1 on one side is connected to the motor 4 through the connecting block 5, and the baffle 1 2 is connected to the screw rod. 8 reinforcement, the baffle plate 2 3 on the other side is fixed on the conveying plate 1, and the baffle plate 2 3 ends are installed with projections 6.

[0021] Preferably, the position of the baffle plate 1 can be moved, and the connecting block 5 is moved by the motor 4, and the connecting block 5 drives the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap