Novel yarn conveying device of double-linen knitting machine

A knitting machine, double blessing technology, applied in the direction of weft knitting, knitting, textile and paper making, etc., can solve the problems of consuming yarn feeding device durability, easy yarn breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

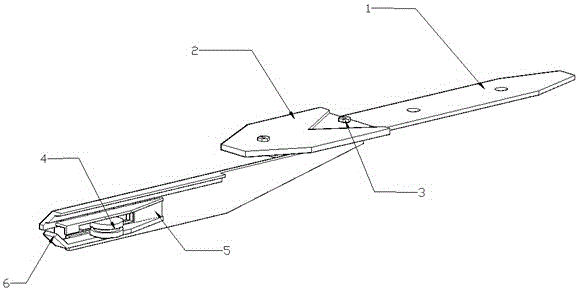

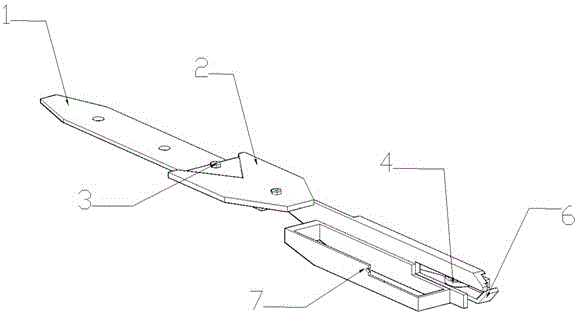

[0015] Please refer to the attached figure 1 , figure 2 , the present invention is a new type of yarn feeding device for Shuangfu linen knitting machine, which consists of 1 sword-shaped plate, 2 finger plates, 3 fixed nuts, 4 yarn guide wheels, 5 yarn guide wheel fixing plates, 6 yarn guide slant plates , 7 yarn hanging slots.

[0016] Wherein, the sword-shaped plate, the finger plate, the fixed nut, and the guide wheel. Yarn guide wheel fixing plate, yarn guiding slant plate, yarn hanging groove; the sword-shaped plate 1 is installed on the right side of the device, the finger board 2 is installed above the left end of the sword-shaped board, and the fixed nut 4 is installed on the finger board Above, the yarn guide wheel 4 is between the yarn guide wheel fixed plates 5, the yarn guide slant plate 6 is installed at the lower end of the yarn guide wheel fixed plates 5, and the yarn hanging groove 7 is on the yarn guide wheel 4 rear side.

[0017] The surface of the sword-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com