Formwork suitable for fabricated beam column post-cast section and installing method thereof

An installation method and prefabricated technology, which are applied in the fields of formwork/template/work frame, on-site preparation of building components, construction, etc., can solve the problems of increasing the construction period, reducing the construction efficiency, occupying the site, etc., to reduce the use and improve the The effect of construction efficiency and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

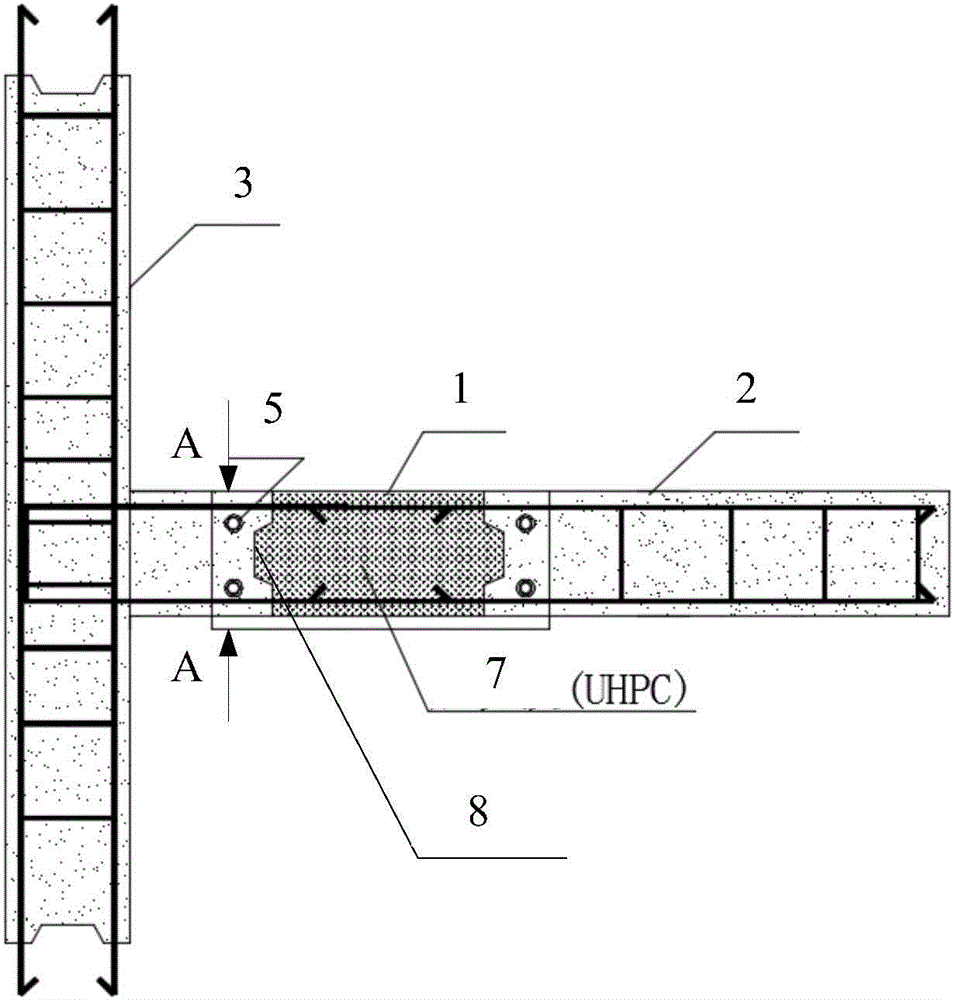

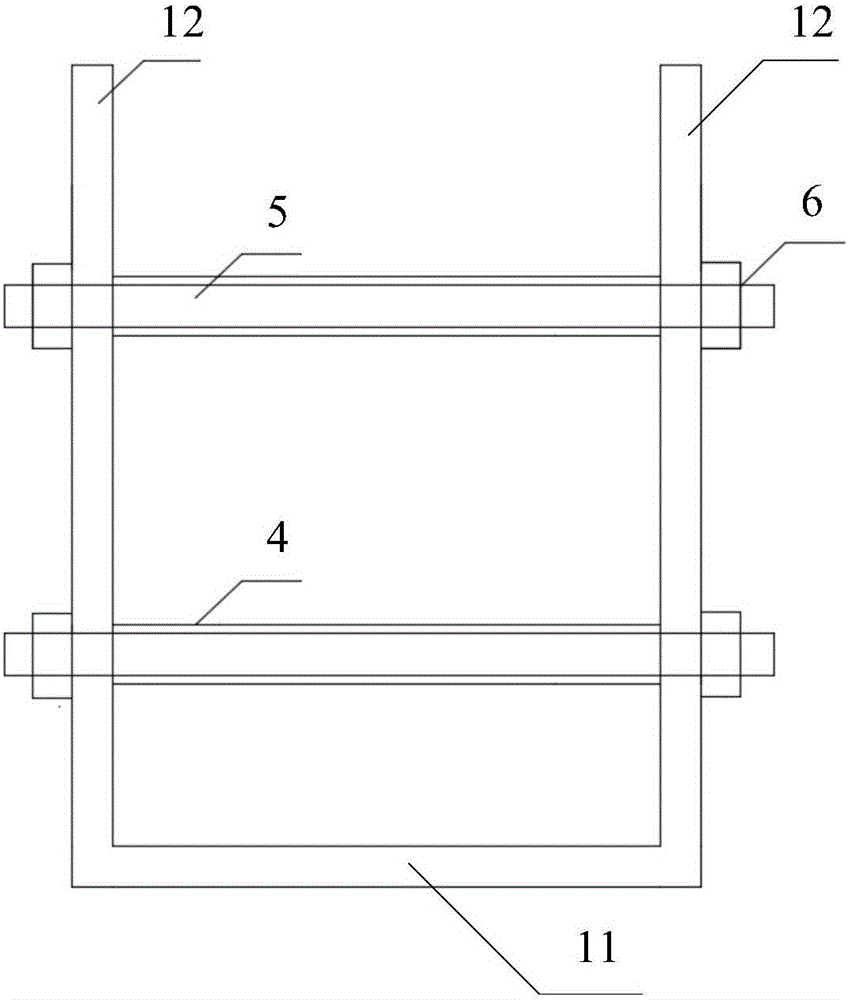

[0032] Such as figure 1 and 2 As shown, the present invention provides a formwork suitable for post-cast sections of fabricated beams and columns, including:

[0033] U-shaped steel formwork 1 is composed of a bottom plate 11 and two side plates 12 connected to the bottom plate 11, the bottom plate 11 and the two side plates 12 form a U-shaped groove, and the two ends of each side plate 11, 12 There are corresponding bolt holes;

[0034] The casing 4 pre-embedded on the edge of the assembled beam 2 or column 3 to be connected, wherein the position of the bolt hole is consistent with the position of the casing 4, ensuring that the hole diameter is just enough for the screw to pass through;

[0035] The screw rod 5 passing throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com