Gravel pile composite foundation liquefaction resistance distinguishing method based on super-pore water pressure ratio

A technology of super pore water pressure ratio and composite foundation, which is applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as increasing the amount of foundation treatment, increasing project investment, and prolonging the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings.

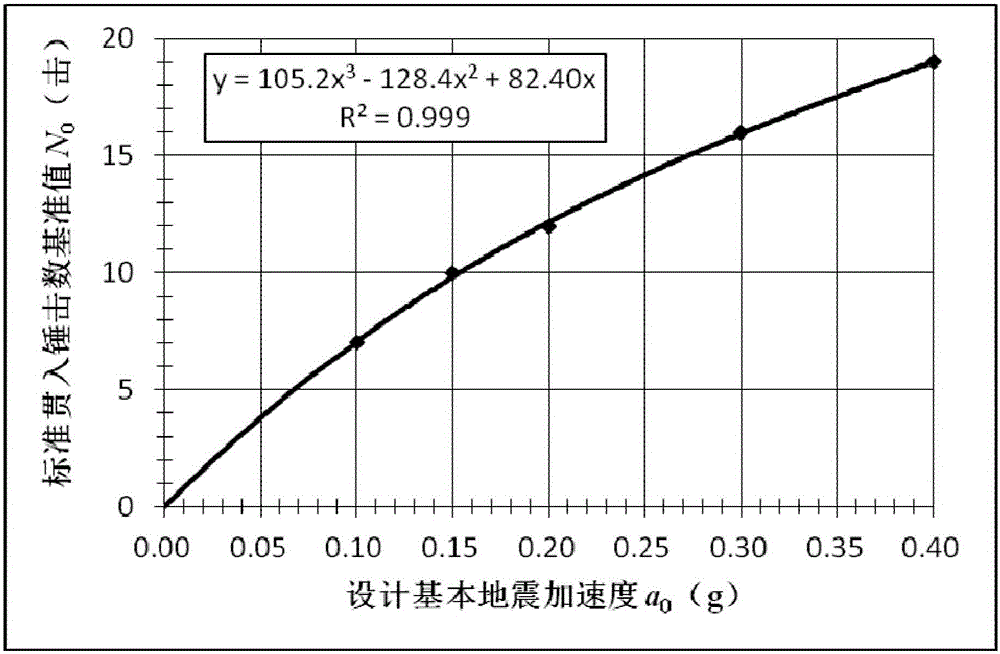

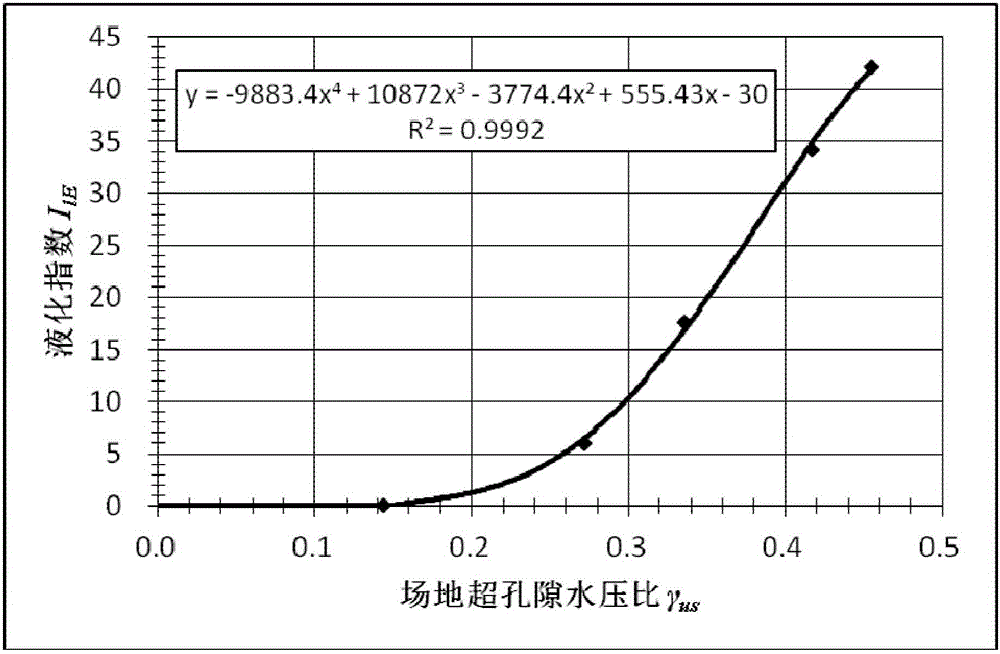

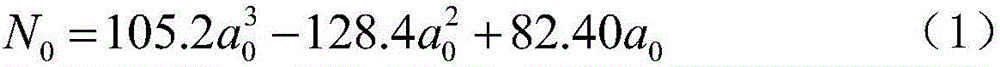

[0049] The anti-liquefaction judgment method of the gravel pile composite foundation based on the excess pore water pressure ratio of the present invention utilizes the relationship between the liquefaction index of the soil site between piles and the excess pore water pressure ratio of the site, and according to the site excess pore of the gravel pile composite foundation Based on the hydraulic pressure ratio, the equivalent liquefaction index of the composite foundation is obtained; according to the size of the equivalent liquefaction index of the composite foundation, the liquefaction level of the gravel pile composite foundation is evaluated according to the current building seismic design code, which overcomes the current building seismic design code Among them, the "standard penetration method" criterion for anti-liquefaction of gravel pile composite foundations o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com