Performance offset-based aeroengine fault diagnosis method

A technology for aero-engine and fault diagnosis, applied in computer parts, instruments, character and pattern recognition, etc., can solve problems such as low practicability of aero-engine fault sample data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0024] Specific embodiment one: a kind of aero-engine fault diagnosis method based on performance offset comprises the following steps:

[0025] Step 1: Acquisition and grouping of aeroengine air path performance data;

[0026] Step 2: According to the grouping results of step 1, the aero-engine performance offset model is established and the performance offset is solved;

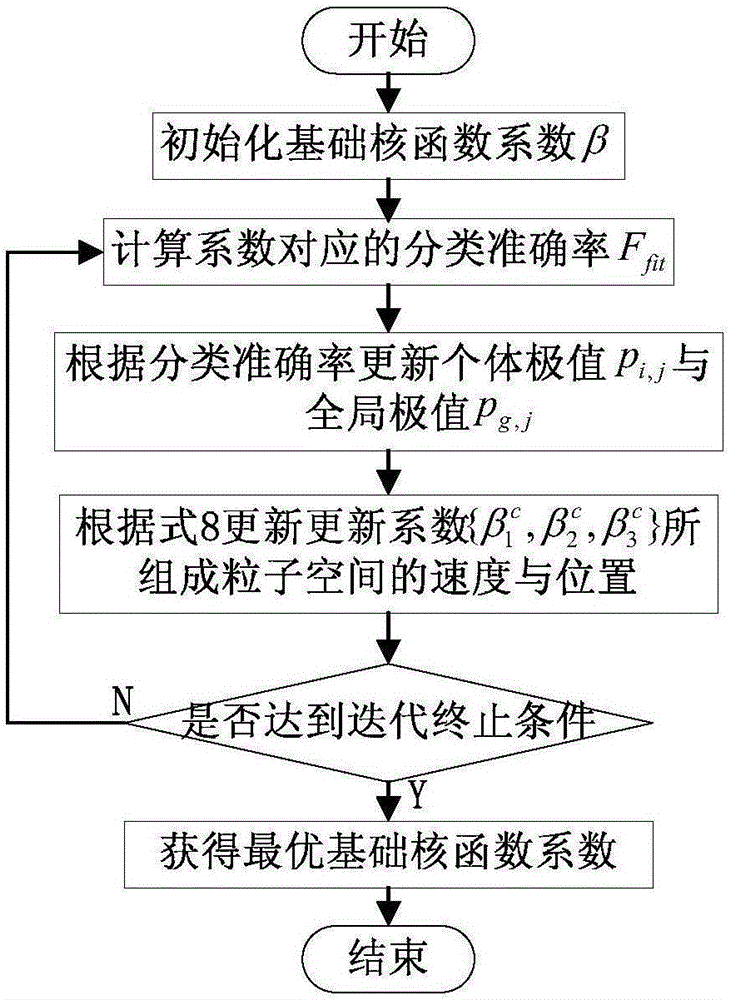

[0027] Step 3: According to the result of solving the performance offset obtained in Step 2, determine the multi-core function of the support vector machine and classify the faults.

specific Embodiment approach 2

[0028] Specific embodiment two: the difference between this embodiment and specific embodiment one is that: the specific process of acquiring and grouping the air path performance data of the aeroengine in the step one is:

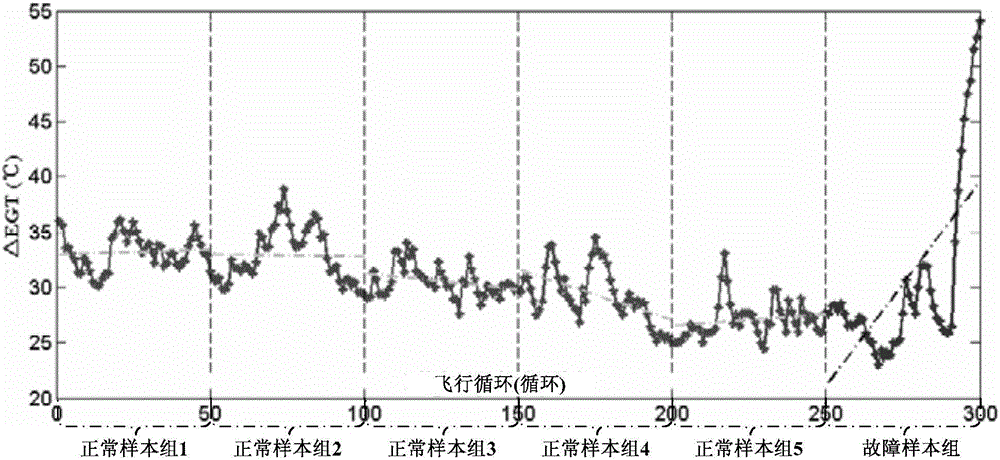

[0029] The air path performance parameters of aero-engines are the basis of engine fault diagnosis. The air path performance parameters of most aero-engines in service are generally transmitted to the ground in quasi-real time through the Aircraft Communications Addressing and Reporting System (ACARS). The operator of the aero-engine will sort it out and send it to the aero-engine manufacturer (Original Equipment Manufacturer, OEM), and the OEM will calculate the performance parameters. The OEM will convert the original air path performance parameters of the engine into a baseline deviation value based on the engine's working condition information, thrust setting, etc. For example: using the working condition information of the aero-engine: flight altitude...

specific Embodiment approach 3

[0044] Embodiment 3: This embodiment is different from Embodiment 1 or 2 in that: the specific process of establishing the aero-engine performance offset model and solving the performance offset in the second step is:

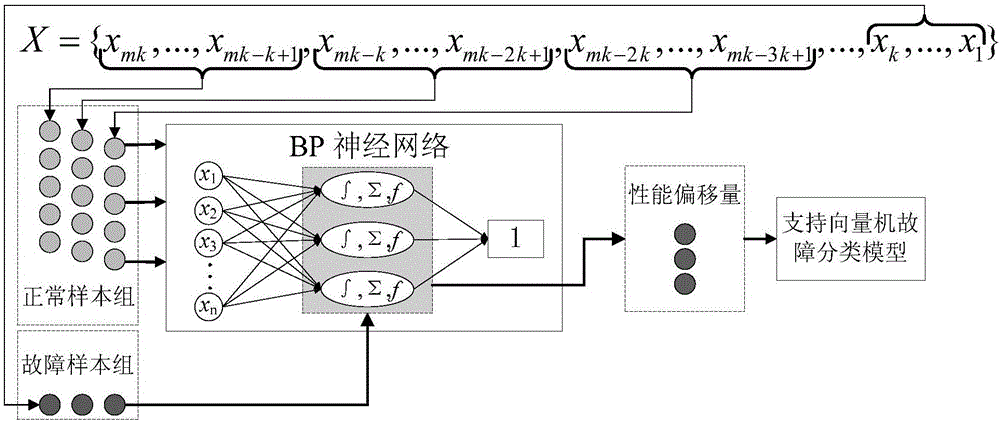

[0045] After obtaining the normal sample data group and fault symptom data sample group of the aero-engine, the BP neural network is used to establish the performance offset calculation model of the aero-engine, the performance parameters of each normal sample group are used as the model input, and the health performance index value 1 is used as the The output expectation of the normal sample group is used to train the engine performance offset neural network; when solving the fault symptom performance offset of the current dismantling, the fault symptom sample group is used as the input of the trained offset neural network model. The output obtained through the model is the performance offset of the engine; the establishment of the performance offset model and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com