Machine vision detecting system for detecting defects of rolling roll grinding surface

A technology of machine vision detection and roll surface, which is applied in the direction of optical testing for flaws/defects, etc., can solve the problems of automatic detection, small effective measurement area, single imaging angle, etc., to eliminate adverse effects, uniform brightness distribution, and imaging clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The implementation method of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. First of all, it should be pointed out that the following descriptions of the specific embodiments and examples of the present invention are intended to better explain the present invention, rather than limit the content of the present invention.

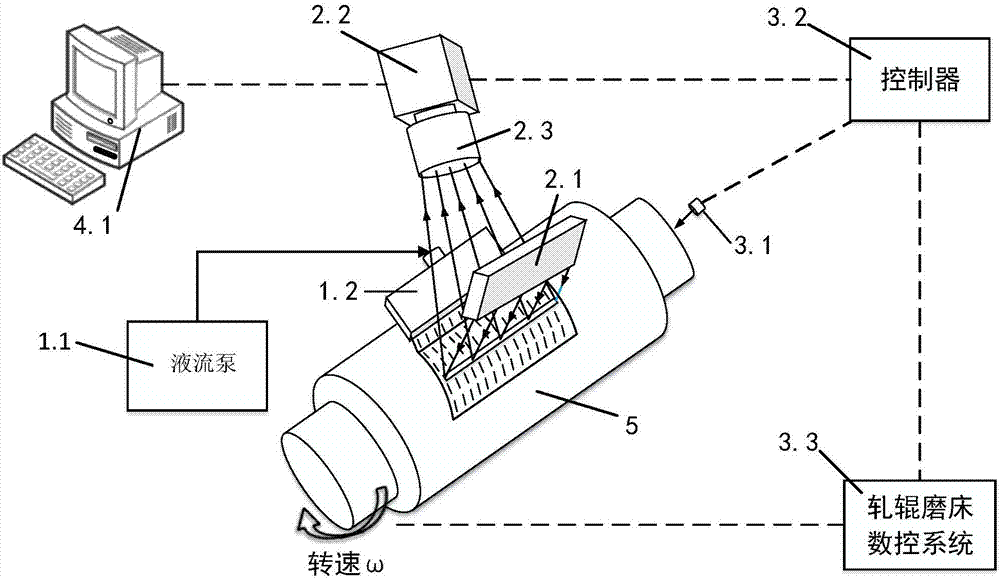

[0040] For this purpose, refer to figure 1 Shown specific embodiment, roll grinding surface defect machine vision detection system of the present invention comprises:

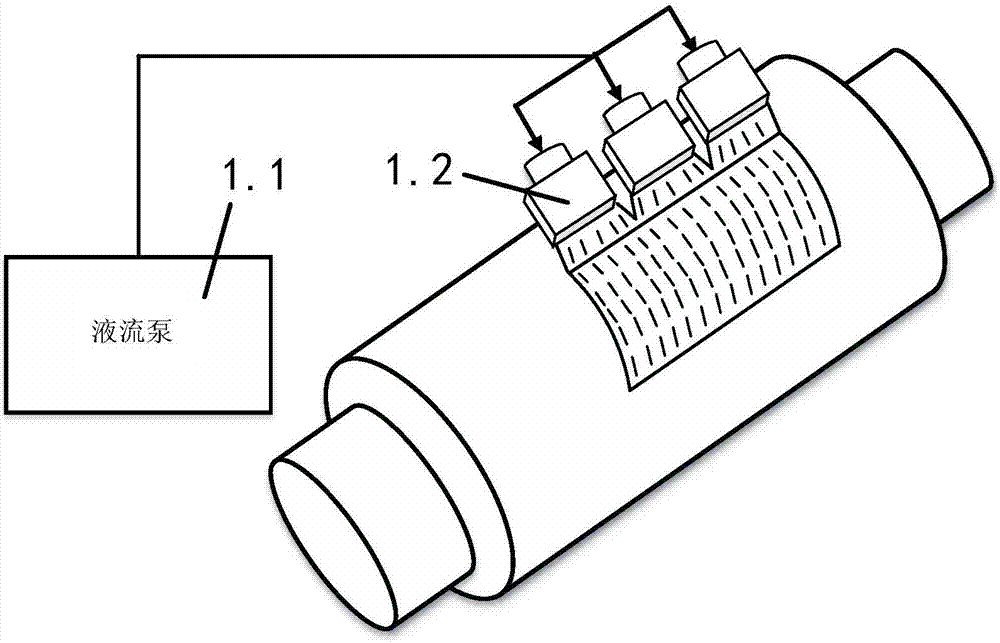

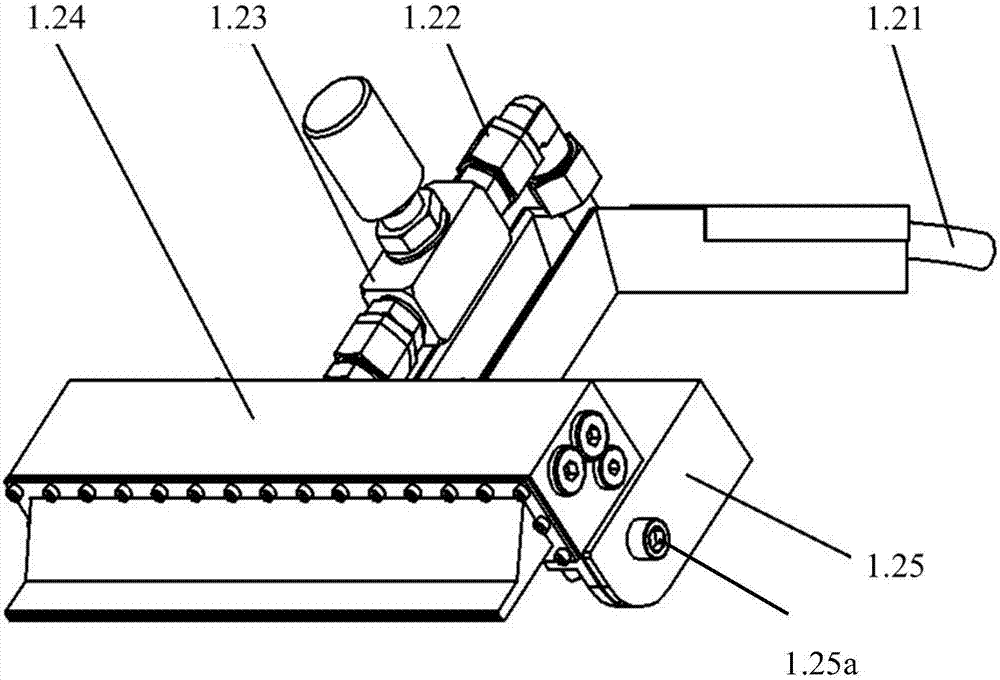

[0041] The cleaning device is set at 0-90 degrees to the normal direction of the surface of the tested roll 5, and the grinding liquid and grinding residues (such as broken abrasive grains and chips, etc.) on the surface of the tested roll after grinding are removed by spraying cleaning liquid. object), and form a uniform laminar liquid layer on the surface of the tested roll 5;

[0042] The image acquisition dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com