Digital mine comprehensive management method and system

A comprehensive management and digital mine technology, applied in image data processing, instruments, etc., can solve problems such as incomplete expression, high production cost, and difficulty in updating, and achieve fast scene drawing speed, reduced production cost, and strong scene interaction ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

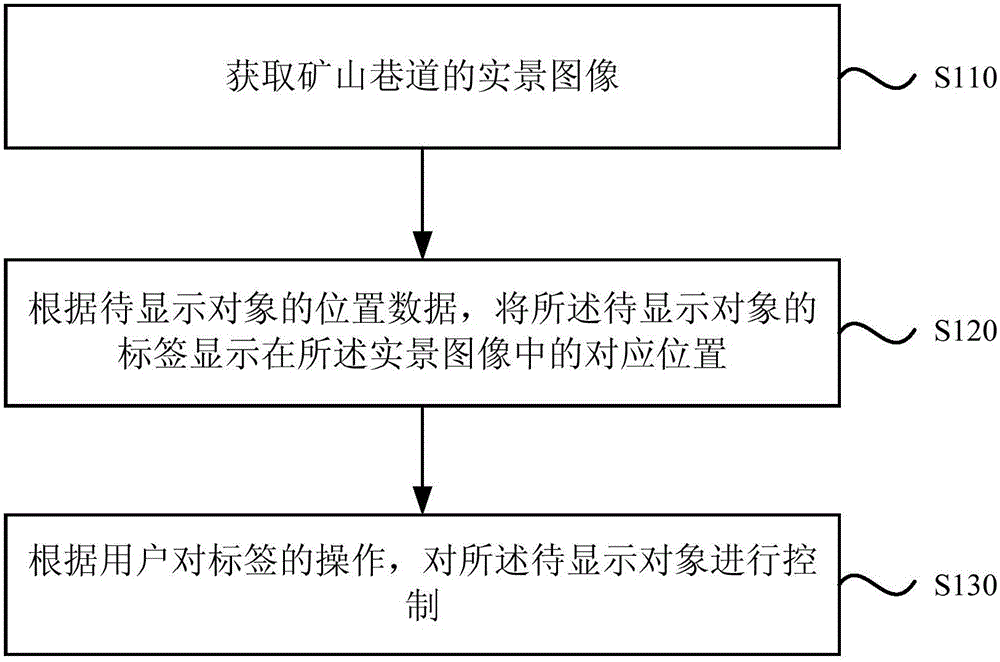

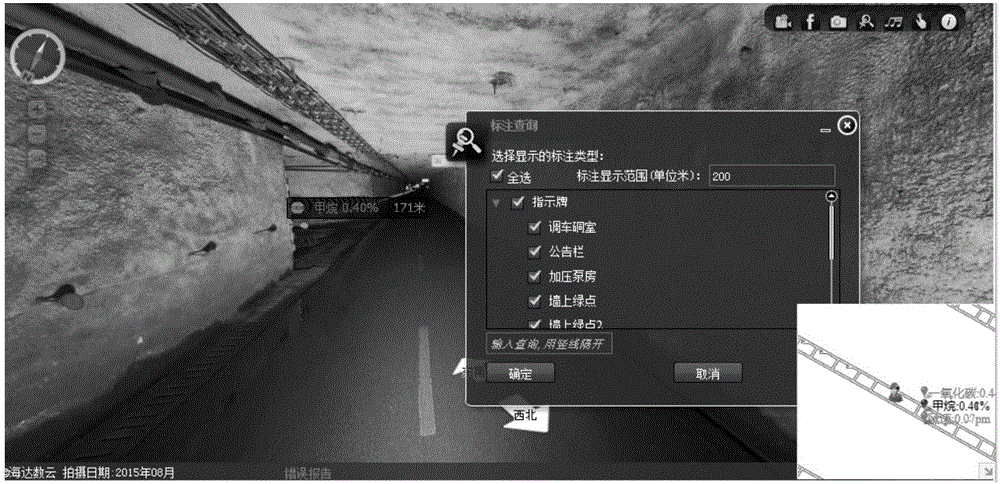

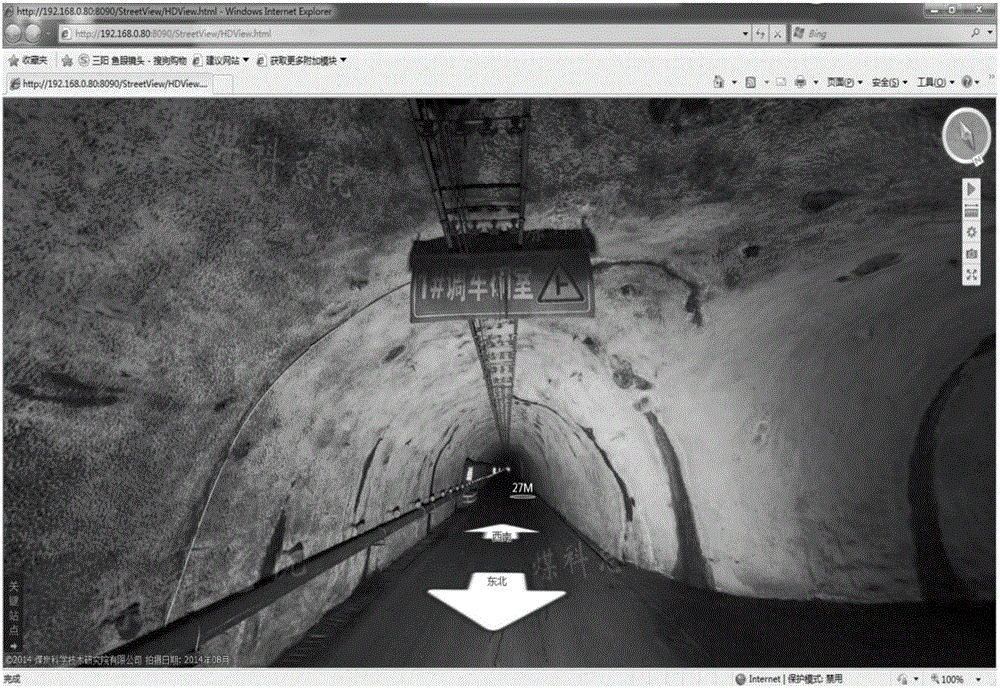

[0052] Please refer to the attached Figure 1A , is a flow diagram of a digital mine comprehensive management method provided in Embodiment 1 of the present invention. This method is applicable to the scene of man-machine dynamic interaction of digital mine comprehensive information. The method is executed by a digital mine comprehensive management system, which can be composed of Software and / or hardware implementation, integrated inside the operator terminal. The method specifically includes the following steps:

[0053] S110. Acquire a real-scene image of a mine roadway.

[0054] Wherein, the method for acquiring real-scene images of mine roadways may be mobile acquisition or fixed-point acquisition.

[0055] Specifically, on the one hand, the panoramic images of various places in the mine roadway can be obtained through mobile acquisition equipment, and the real-scene images can be formed by splicing. Due to the complex environment, long distance, poor light, and heavy i...

Embodiment 2

[0089] Please refer to the attached image 3 , is a schematic structural diagram of a digital mine comprehensive management system provided in Embodiment 2 of the present invention, the system specifically includes the following modules:

[0090] Real-scene image acquisition module 210, used to obtain the real-scene image of mine roadway;

[0091] A label display module 220, configured to display the label of the object to be displayed at a corresponding position in the real scene image according to the position data of the object to be displayed;

[0092] The object to be displayed control module 230 is configured to control the object to be displayed according to the user's operation on the label.

[0093] Preferably, the label display module includes:

[0094] a data acquisition unit, configured to acquire spatial position data of the object to be displayed;

[0095] A position determination unit, configured to determine the position of an object corresponding to the objec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com