Polymer conductive film with adjustable electromagnetic shielding performance and its preparation method

A conductive film, electromagnetic shielding technology, applied in the direction of magnetic field/electric field shielding, electrical components, etc., can solve the problems of poor interface compatibility, inconvenient method, increase the mechanical brittleness of polymer conductive film materials, etc., to achieve good mechanical properties and The effect of flexibility, improving mechanical strength, and good electromagnetic shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 3g of graphene and 12g of thermoplastic polyurethane (TPU) were added to 120mL of N,N-dimethylformamide at a mass ratio of 1:4, and a TPU / TPU with a graphene content of 20wt% was prepared by solution blending. Graphene composite dispersion, the viscosity of the composite dispersion is 383mPa s;

[0024] The above-mentioned TPU / graphene composite dispersion is brushed on both sides of a polyester non-woven fabric with a thickness of 100 microns, and a polymer / graphene conductive film with a conductive coating thickness of 25 microns is obtained after drying the solvent. The tensile strength of the above-mentioned film is 60 MPa, and it does not break after being folded in half repeatedly for 1000 times.

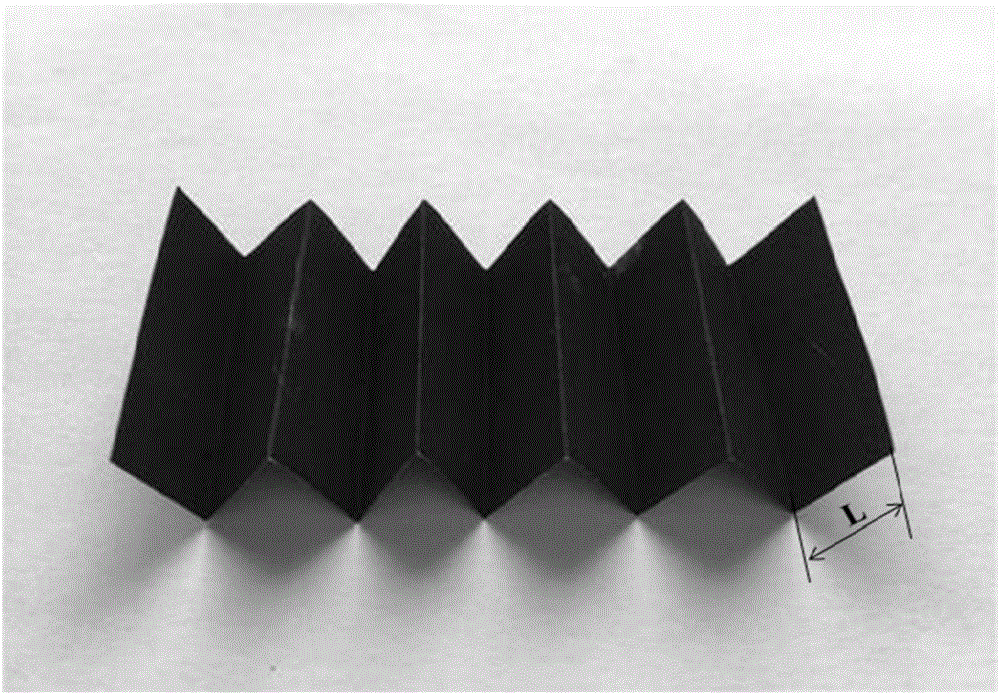

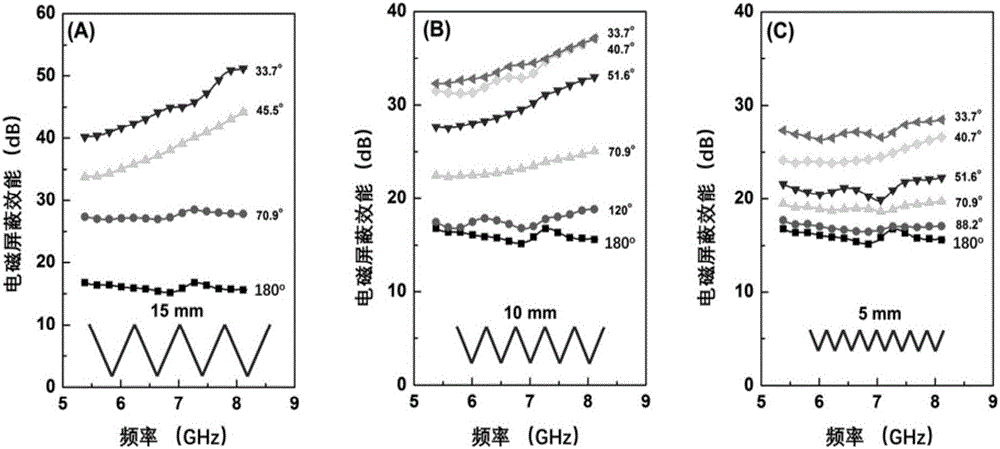

[0025] The above polymer / graphene conductive film is zigzag folded to obtain a polymer conductive film with a zigzag structure, and the folded optical photo is as follows figure 1 As shown, the sawtooth side length L is 15 mm, and the sawtooth angle can be changed betw...

Embodiment 2

[0027] Compared with Example 1, other preparation steps are the same, the only difference is that when the polymer / graphene conductive film is zigzag folded, the zigzag side length L is 10 mm, and the zigzag structure formed after folding is stretched or compressed To achieve the change of the sawtooth angle between 180 and 0 degrees, the electromagnetic shielding effectiveness test is carried out in the C-band (frequency 5.38-8.17GHz), and the results are as follows figure 2 Shown in B. The results show that the electromagnetic shielding effectiveness of the material can be adjusted by simply stretching or compressing the sawtooth structure of the polymer conductive film to change the sawtooth angle. When the sawtooth angle changes from 180 degrees to 33.7 degrees, the average electromagnetic shielding effectiveness of the material Varies between 16.0dB and 34.3dB.

Embodiment 3

[0029] Compared with Example 1, other preparation steps are the same, the only difference is that when the polymer / graphene conductive film is zigzag folded, the zigzag side length L is 5 mm, and the zigzag structure formed after folding is stretched or compressed To achieve the change of the sawtooth angle between 180 and 0 degrees, the electromagnetic shielding effectiveness test is carried out in the C-band (frequency 5.38-8.17GHz), and the results are as follows figure 2 C shown. The results show that the electromagnetic shielding effectiveness of the material can be adjusted by simply stretching or compressing the sawtooth structure of the polymer conductive film to change the sawtooth angle. When the sawtooth angle changes from 180 degrees to 33.7 degrees, the average electromagnetic shielding effectiveness of the material Varies between 16.0dB and 27.2dB.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com