Special mandrel tool for accurately grinding excircle of main shaft of high-precision numerical control machine tool

A CNC machine tool and high-precision technology, which is applied in the direction of grinding workpiece supports, machine tools designed for grinding workpiece rotating surfaces, and grinding machines. requirements, it is difficult to ensure the accuracy of the outer circle of the spindle, etc., to achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

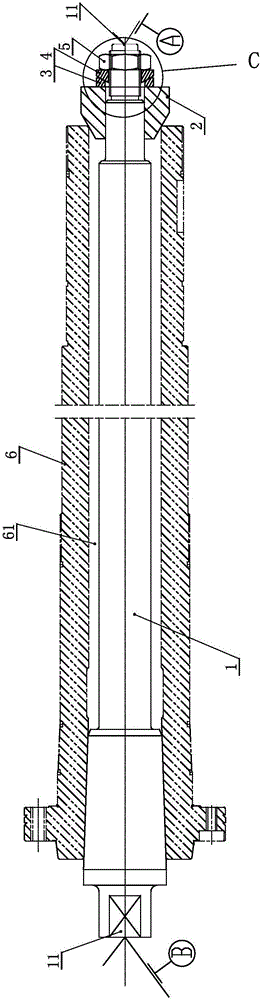

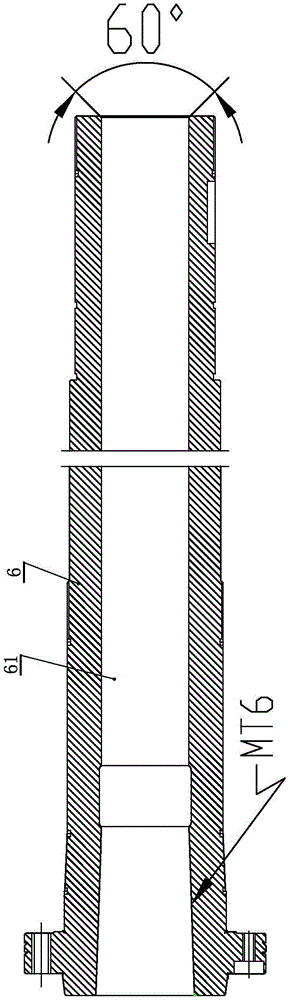

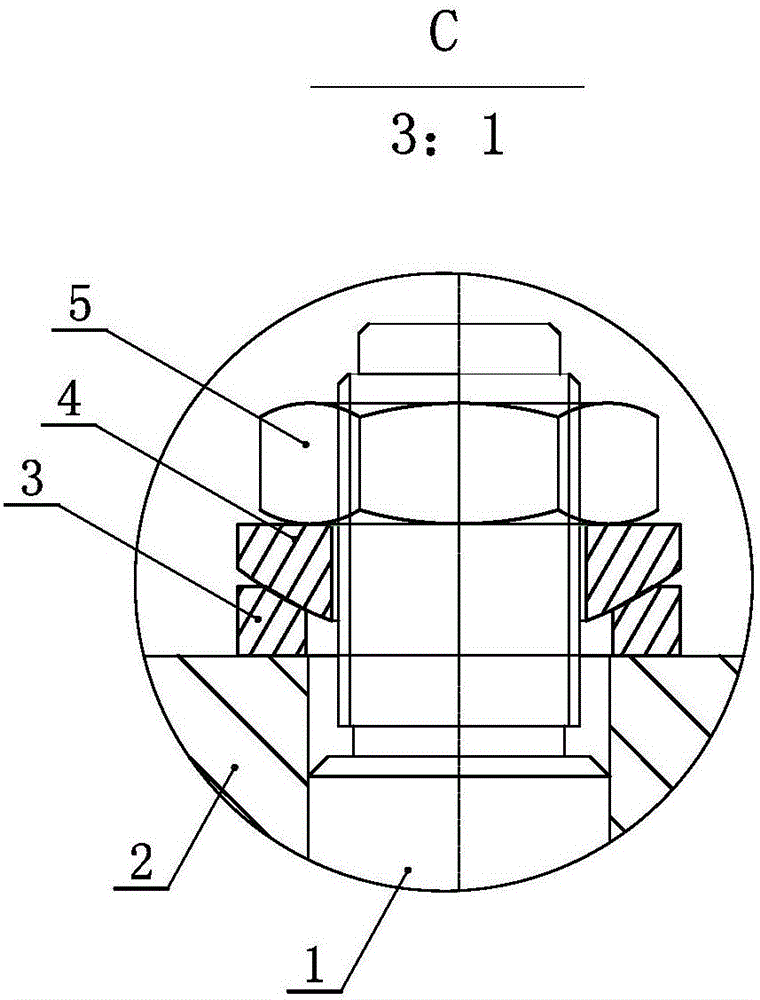

[0017] The following is attached Figure 1-3 The features and principles of the present invention are described in detail, and the examples given are only used to explain the present invention, not to limit the protection scope of the present invention.

[0018] This invention is designed for the spindle parts with high precision requirements, and the center of the spindle part 6 to be processed is provided with a central hole 61, the central hole is a through hole, the left end of the central hole is a left taper hole, and the right end is a right taper hole, such as figure 2 shown. like figure 1 As shown, the design includes a grinder mandrel body 1, a 60° tapered pressure block 2, a tapered washer 3, a spherical washer 4 and a fixing piece. Wherein the grinder mandrel body is a slender shaft, the grinder mandrel body runs through the central hole of the main shaft to be processed and the right end of the grinder mandrel body passes through the right taper hole and extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com