Stepless adjustable pipe supporting device

An infinitely adjustable, tube support technology, applied to workbenches, manufacturing tools, etc., can solve the problems of difficulty in meeting the needs of tube prefabrication, limited types and quantities of tube supports, and low utilization rate, achieving simple structure and improved utilization The effect of high efficiency and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

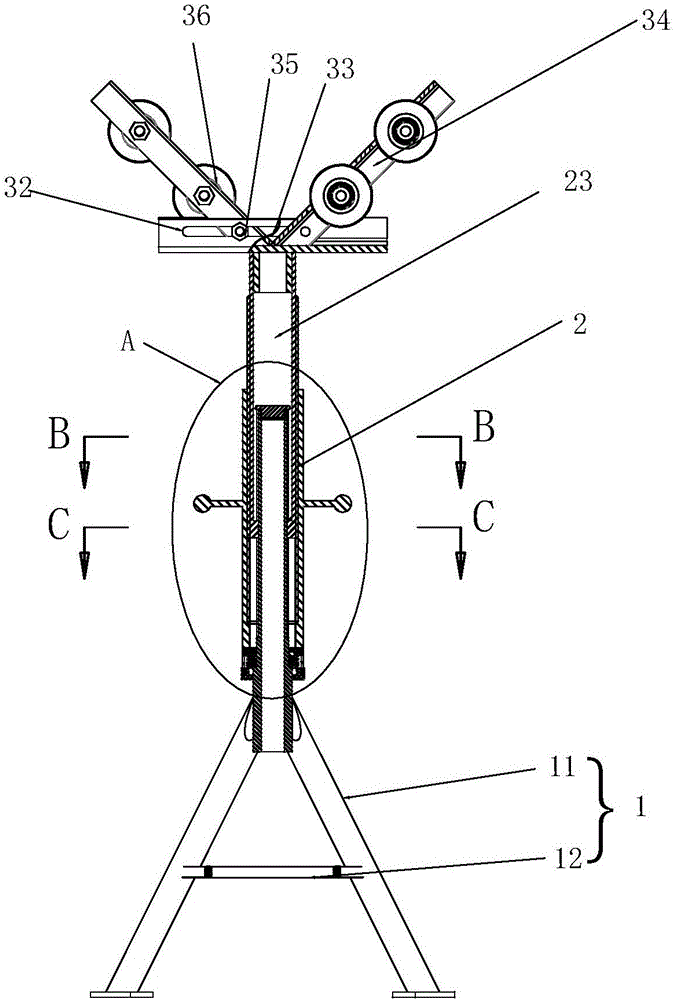

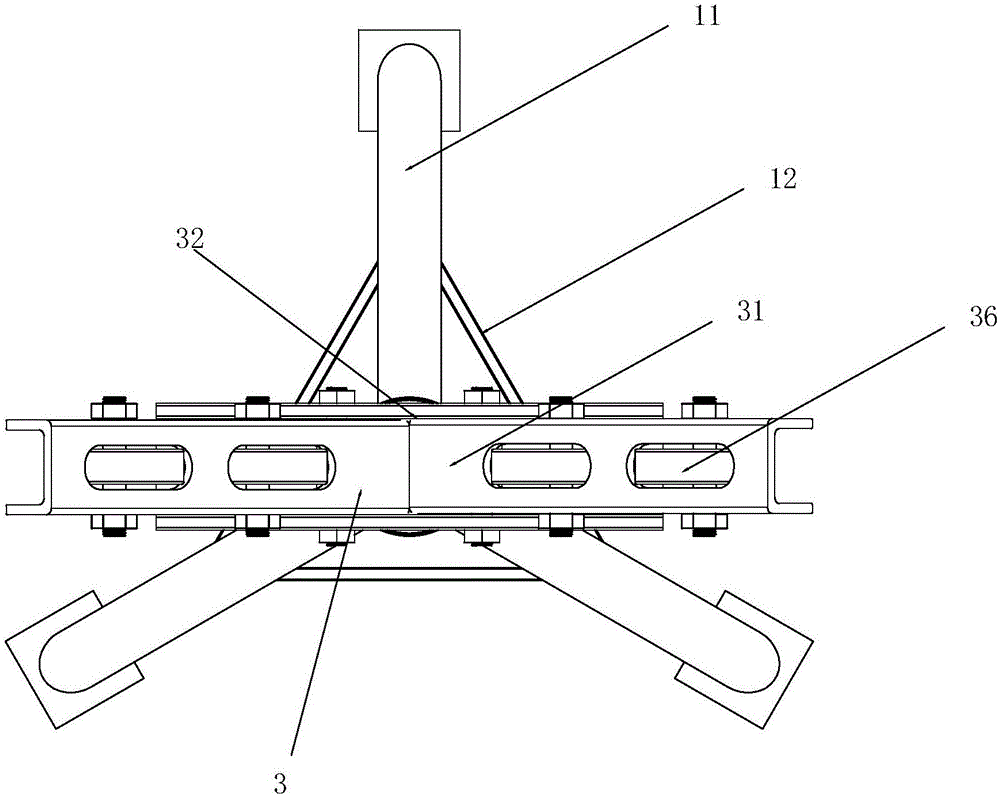

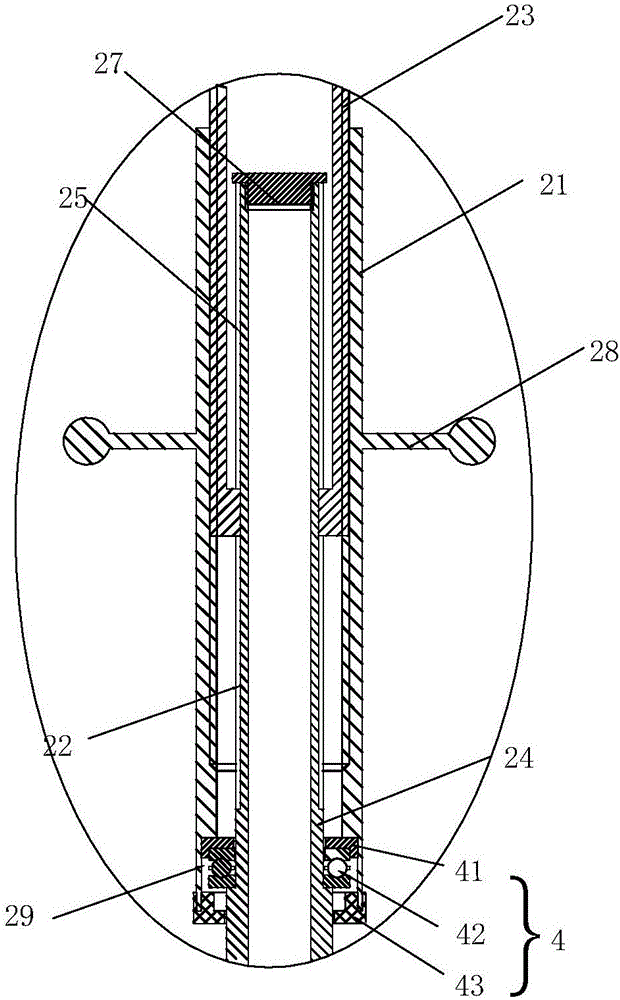

[0023] see Figure 1 to Figure 5 , an infinitely adjustable pipe support device of the present invention, comprising a support 1, a telescopic assembly 2 installed on the support 1, and a support assembly 3, the telescopic assembly 2 includes an outer cylinder 21, an inner cylinder 22 and a telescopic Cylinder 23, the lower part of the telescopic cylinder 23 is slidably fitted on the upper part of the inner cylinder 23, the upper part of the outer cylinder 21 is threaded on the telescopic cylinder 23, and the outer wall of the inner cylinder 22 is provided with a second A stepped platform 24 , the upper part of the first stepped platform 24 is provided with a spline groove 25 , and the inner cylinder 22 is slidably connected with the telescopic cylinder 23 through a spline 26 . The upper end of the inner cylinder 22 is connected with an anti-off cap 27, and the anti-off cap 27 is screwed on the inner wall of the inner cylinder 22; Exceeding its extreme position during ascent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com