A kind of reaction injection pultrusion molding equipment and reaction injection pultrusion molding method

A pultrusion molding and reaction technology, applied in the field of reaction injection pultrusion molding equipment, can solve the problems of inability to achieve long-term continuous production, failure to make full use of low resin viscosity, poor resin stability, etc., and to reduce the volatilization of toxic resin vapors. , The effect of improving resource utilization and reducing resin loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

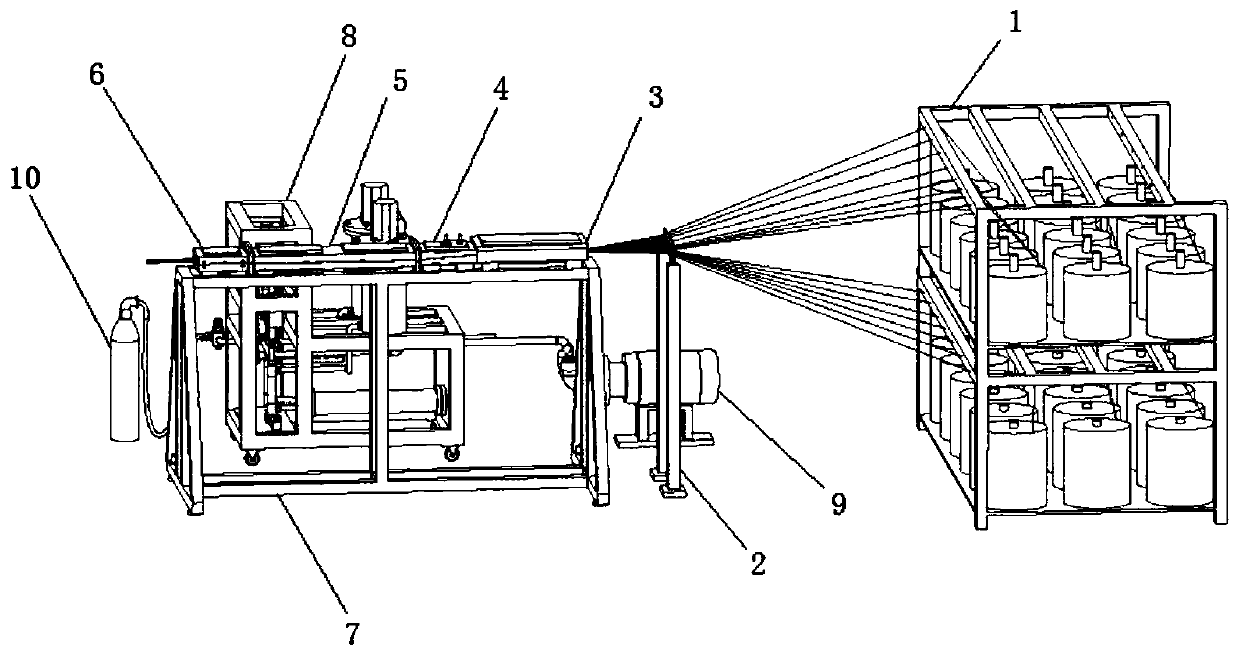

[0055] Such as Figure 1-4 As shown, this embodiment provides a reaction injection pultrusion molding equipment, including:

[0056] A molding unit for molding resins and fibers, said molding unit comprising at least four of the following sequentially connected processing sections forming a closed processing channel with two ports:

[0057] Preheating section 3, used to preheat the fibers;

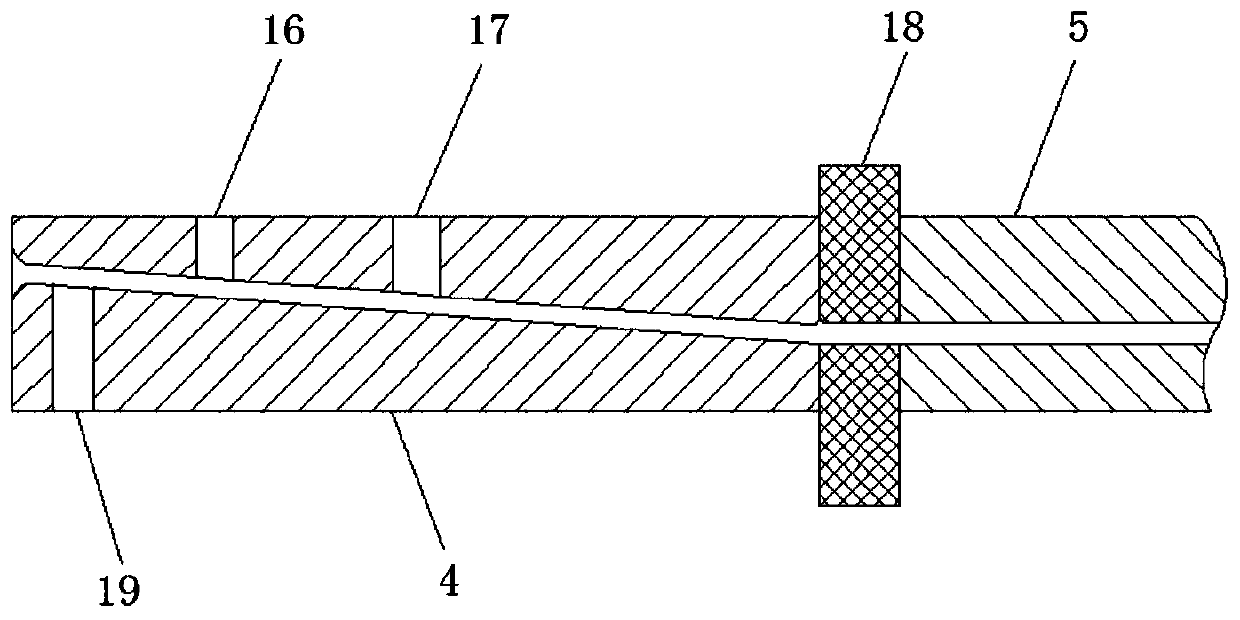

[0058] The impregnation section 4 is used to impregnate the resin and the preheated fibers;

[0059] The heating section 5 is used to make the impregnated fibers undergo a curing reaction;

[0060] The cooling section 6 is used for cooling and forming the composite material after the solidification reaction occurs.

[0061] Preferably, the temperature in the preheating section 3 is 120-240° C., and the preheating time of the fibers is 5-20 minutes; the preheated fibers can be better impregnated with resin.

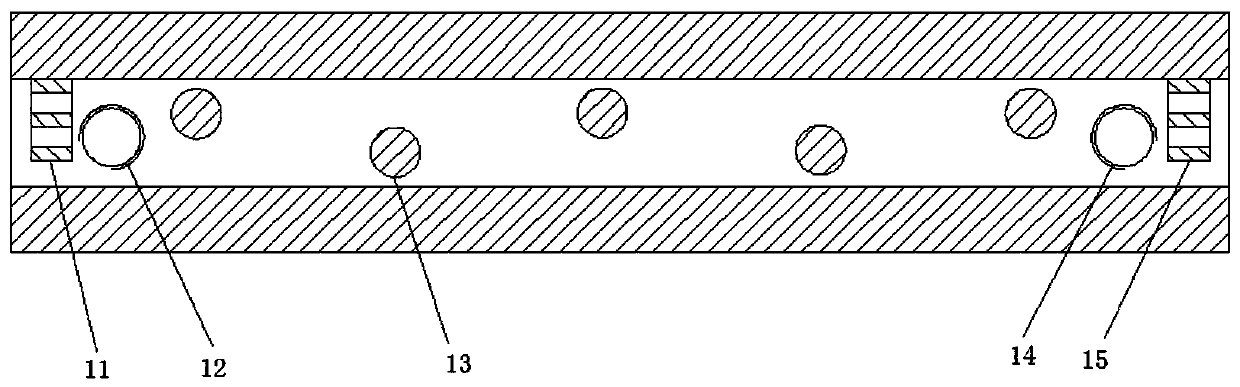

[0062] Preferably, the two ends of the preheating section 3 are provided with ...

Embodiment 2

[0085] 50 parts by weight of caprolactam, 2 parts by weight of sodium caprolactam and 0.5 parts by weight of methyl silicone oil, 50 parts by weight of caprolactam, 2 parts by weight of hexamethylene-1,6-diformyl caprolactam and 0.5 parts by weight of methyl silicone oil are added to the resin The two resin tanks provided with the unit were heated to 90°C, and vacuum dehydrated for 10 minutes, and kept in a stirring state. After vacuum dehydration, nitrogen was passed into the resin tank for protection.

[0086] The glass fiber bundles are pre-arranged through the cluster plate, and then guided through the preheating section 3, impregnating section 4, heating section 5, cooling section 6, and finally fixed on the tractor. Thread the injection gun and nitrogen pipeline to the impregnation section 4, feed nitrogen, start the plunger metering pump and tractor, and start production.

[0087] The hot air flow in the preheating section 3 is 160°C, the residence time is 15 minutes, t...

Embodiment 3

[0091] Put 50 parts by weight of caprolactam, 4 parts by weight of caprolactam magnesium bromide and 1 part by weight of simethicone oil, 50 parts by weight of caprolactam, 4 parts by weight of N-acetylated caprolactam and 1 part by weight of simethicone oil on the two sides of the resin providing unit. heated to 100°C in a resin tank, and vacuum dehydrated for 15 minutes, and kept in a stirring state. After vacuum dehydration, nitrogen was introduced into the resin tank for protection.

[0092] The carbon fiber bundles are pre-arranged through the cluster plate, and then guided through the preheating section 3, impregnating section 4, heating section 5, cooling section 6, and finally fixed on the tractor. Thread the injection gun and nitrogen pipeline to the impregnation section 4, feed nitrogen, start the plunger metering pump and tractor, and start production.

[0093] The hot air flow in the preheating section 3 is 180°C, the residence time is 10 minutes, the temperature i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com