Small box cigarette packet visual detecting and removing device

A technology of visual detection and rejection device, which is applied in the packaging of cigars and cigarettes, etc. It can solve the problems of missing/reversed seals, poor cutting of aluminum foil paper on the detection surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

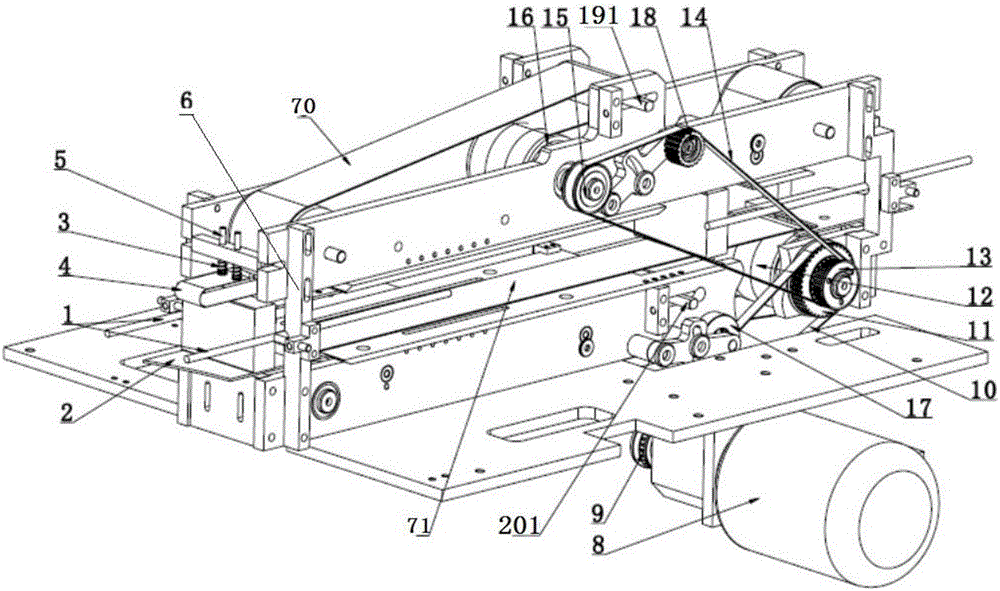

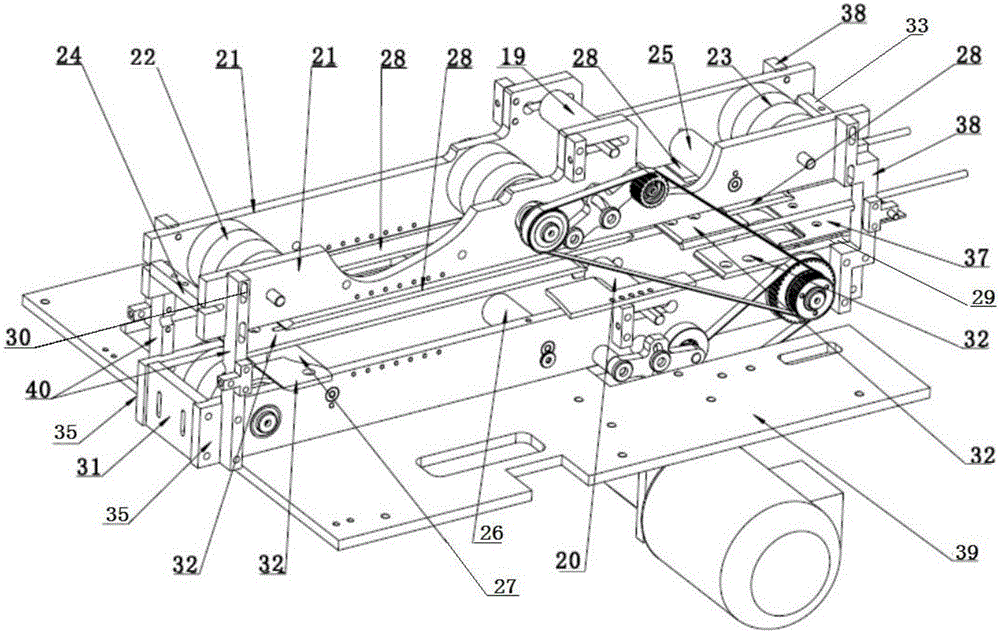

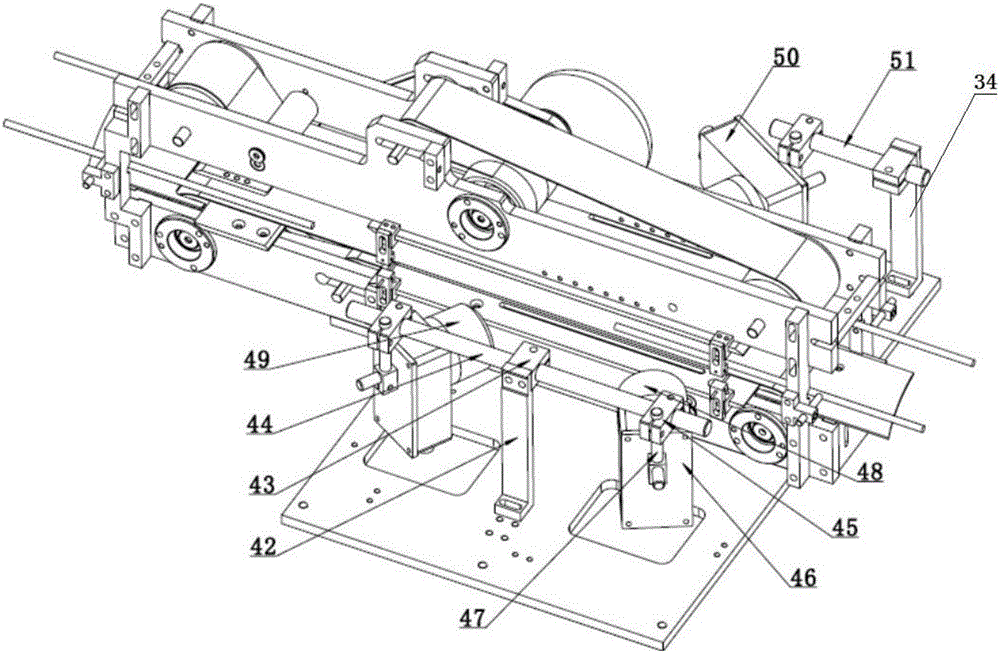

[0035] Embodiment: A visual detection and elimination device for the appearance of small packs of cigarettes, which is used to connect between the soft pack packaging machine and the pack of small packs of transparent paper. system, placed on the frame 56, the appearance visual inspection system located around the cigarette bale detection and conveying system, placed on the frame 56, the defective cigarette bale rejecting system located at the tail of the cigarette bale detection and conveyance system, the appearance visual inspection system is connected to the defective cigarette Packet rejecting system; the cigarette pack detecting and conveying system includes upper and lower two sets of upper plane conveyor belts 70 and lower plane conveyor belts 71 rotating at the same speed, the conveying speed of the upper and lower plane conveyor belts is higher than that of the small box cigarette packaging machine for cigarette pack conveying speed. The device adopts an independent m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com