Automatic management cabinet and management method for machine tool cutter

A technology for automatic management and knives, applied in transportation, packaging, storage devices, etc., can solve the problems of surprising waste of knives, opaque data of knives, error-prone, etc., to avoid borrowing and misappropriation, avoid inconsistent accounts, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

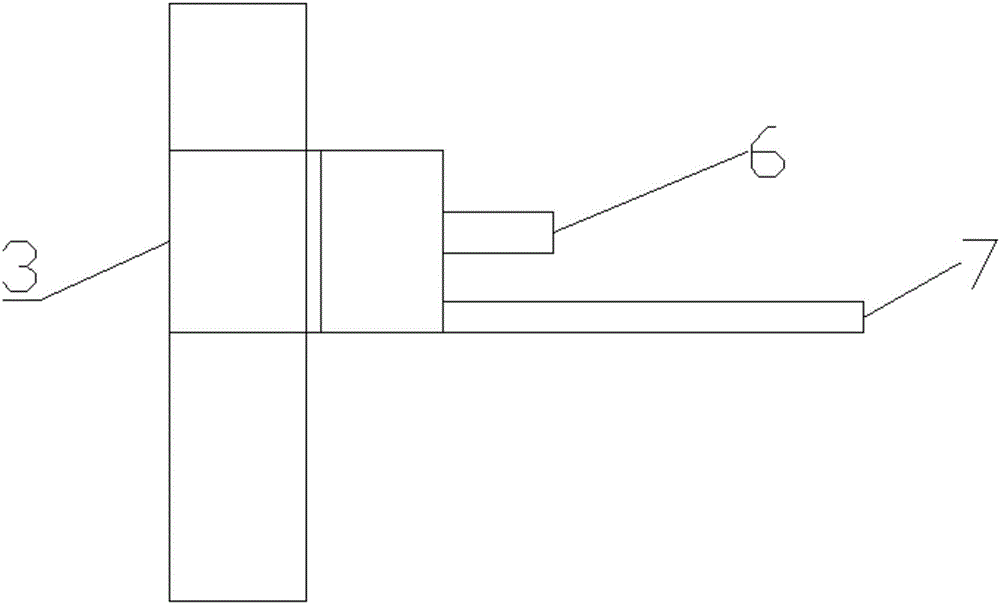

[0055]Embodiment 2 is different from Embodiment 1 in that the cutter moving device 3 is also provided with a cutter placement plate 7 for placing the cutter, and the cutter placement plate 7 is arranged below the push rod 6. Under the control of the controller, The tool placed on the plate can be pushed into the compartment of the tool storage device 2 via the push rod 6 . Through this setting, this product can realize the function of automatic tool return. Specifically, when the user returns the tool, place the tool that should be returned on the tool placement plate 7, and obtain the tool code by scanning the identification code on the tool packaging tube or according to the user’s The tool code is manually input, and the controller automatically controls the tool moving device to move to the grid at the corresponding position. At this time, the tool placement plate 7 is smoothly docked with the lower surface of the grid position, and the controller controls the push rod 6 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com