A method for deep denitrification and dephosphorization of sewage

A technology for sewage and sewage treatment devices, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, biological water/sewage treatment, etc. problems such as operating costs and sludge treatment and disposal costs increase, to achieve the effect of reducing residence time, reducing operating costs, and saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The design of embodiment 1 denitrification and dephosphorization device

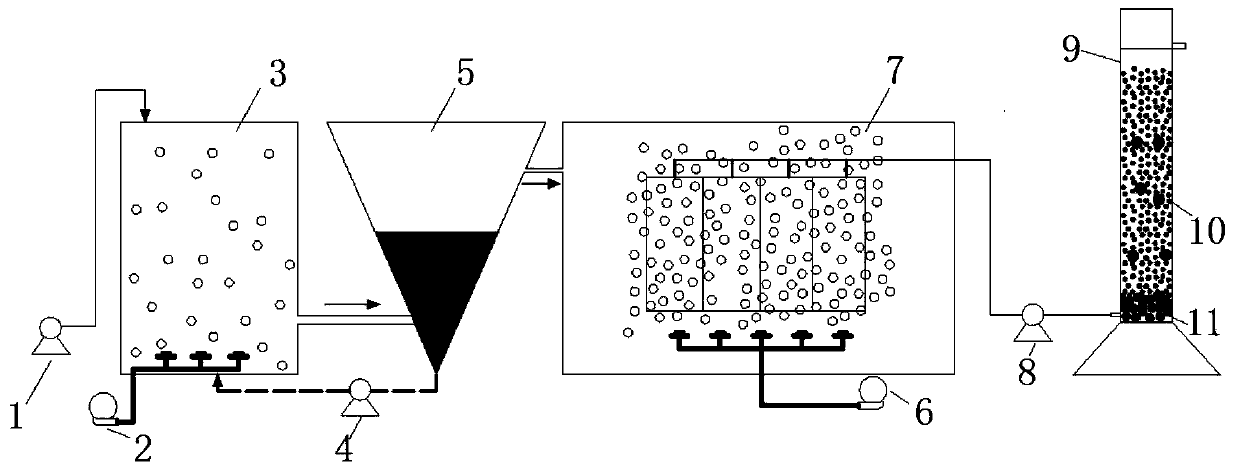

[0026] Such as figure 1 As shown, an acrylic plate is used to prepare a nitrogen and phosphorus removal device. The nitrogen and phosphorus removal device includes a biosorption tank 3, a sedimentation tank 5, an MBR tank 7 and a sulfur-iron autotrophic denitrification tank 9, and the effective volumes are 1.5L, 12L, 21L and 4.8L; the biosorption tank 3 is connected to the water inlet through the water inlet pump 1, and the lower part is connected to the first fan; The MBR pool 7 is connected; the MBR pool 7 adopts a 0.02 μm flat film, and the ventilation pipeline is arranged in the MBR pool 7, and the pipeline is connected with the second fan 6; an MBR outlet pump is set between the MBR pool 7 and the sulfur iron autotrophic denitrification pool 9 8, thus the pump sucks out water from the MBR pool 7, and pumps it into the sulfur-iron autotrophic denitrification tank; the sulfur-iron autotrophic ...

Embodiment 2

[0028] Embodiment 2 biosorption section operation

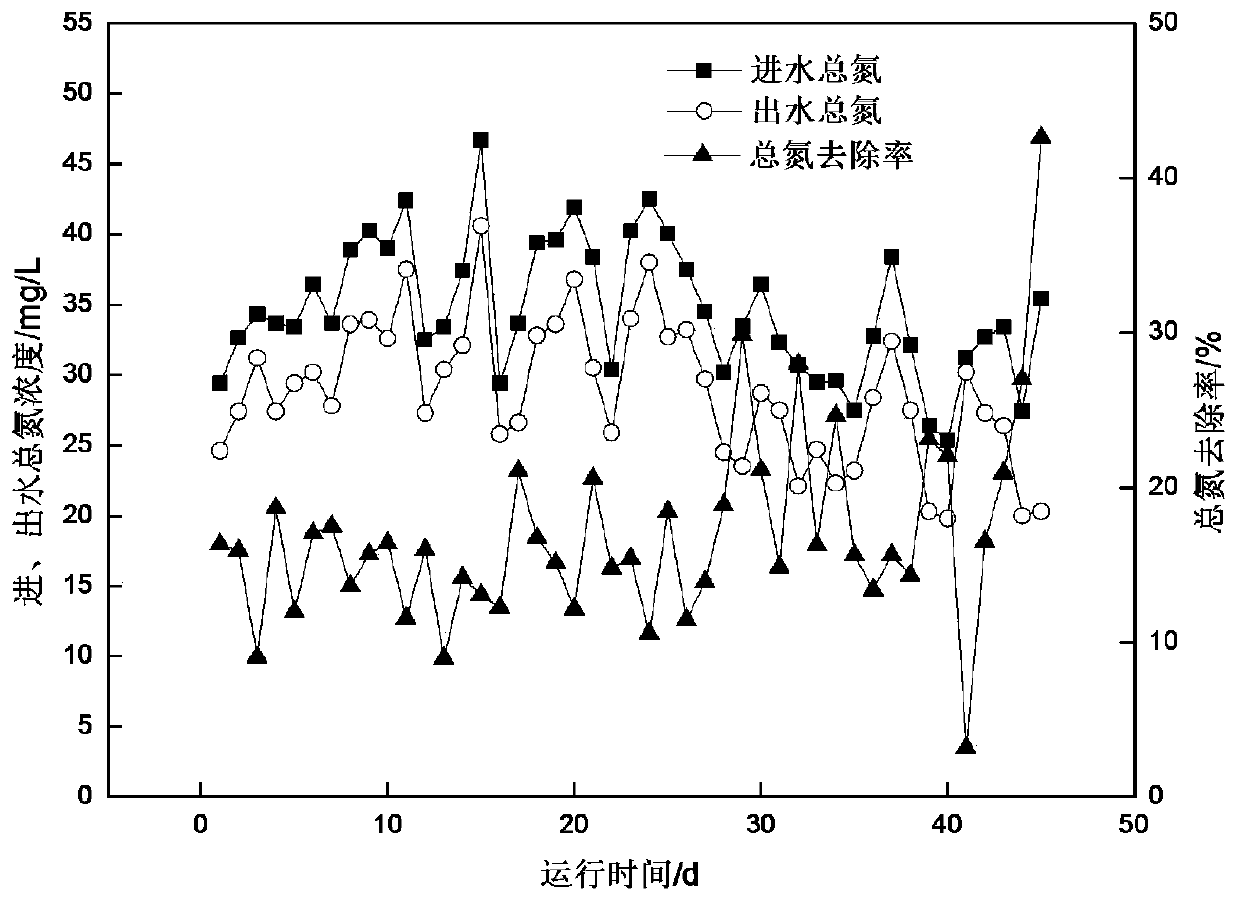

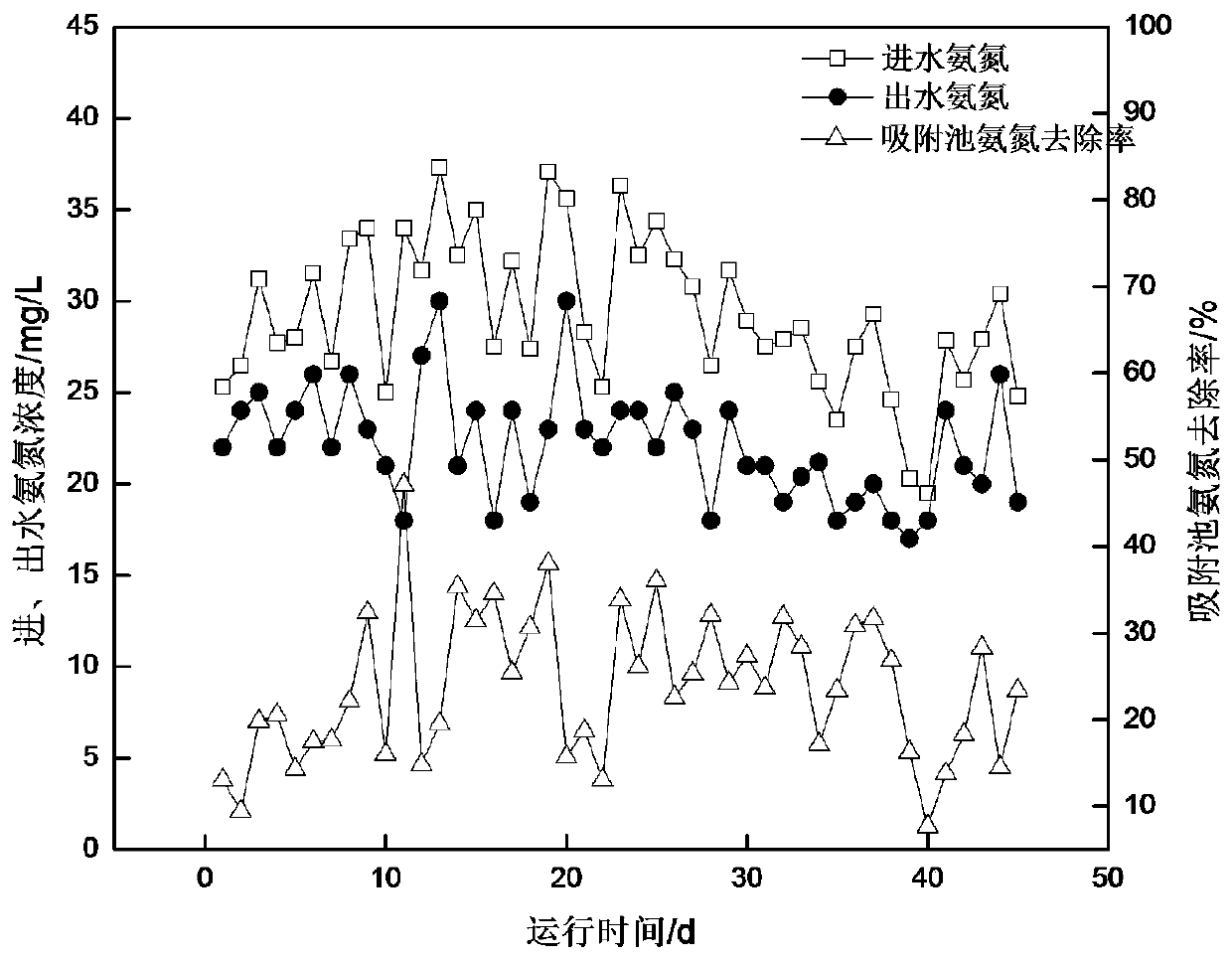

[0029] Such as Figure 2-5 As shown, most of the total nitrogen content of the test device influent is dissolved ammonia nitrogen, accounting for an average of 85%. The concentration of total phosphorus ranges from 0.89 to 5.4 mg / L, with an average value of 2.8 mg / L. Influent COD is 150-456mg / L, with an average value of 288.6mg / L. The biosorption section is to cultivate prokaryotic microorganisms that are adapted to the raw water environment and can achieve rapid proliferation by controlling the shorter HRT and SRT to adsorb the particulate matter in the influent, so the biosorption section has a good ability to remove COD in the influent . The range of effluent COD in the biological adsorption section is 76-102mg / L, the average value is 90.2mg / L, and the average removal rate is 66.6%. The removal rates of ammonia nitrogen and total nitrogen were both low, with an average of 17%, because the HRT was short and ammonia nitr...

Embodiment 3

[0031] Example 3 Phosphorus and nitrogen removal device for sewage treatment

[0032] Run the device of Example 1, control the hydraulic retention time (HRT) of the biosorption section to be 0.35-0.7h, the sludge age (SRT) to be 1.5-3d, the dissolved oxygen (DO) range to be 0.5-1mg / L, and the mixed liquor to be suspended The solid concentration (MLSS) is 4000-5000mg / L ( Figure 6 ). The HRT of the sedimentation tank is 2-3h. MBR adopts 0.02μm flat membrane, membrane flux is 8-12L / m 2 .h, HRT is 6-8h, SRT is 18-22d, DO range is 5-7mg / L, MLSS is maintained at 6500-8000mg / L; the inner diameter of sulfur iron autotrophic denitrification filter is 10cm, and the effective height is 60cm. The control HRT range is 2-3h.

[0033] Under the condition that the above operation method remains unchanged, different iron filling ratios are used for sewage treatment, as shown in Table 1, the higher the iron filling ratio, the lower the total phosphorus concentration in the effluent; but wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com