A method for producing gasoline and clean diesel from coal-based inferior raw materials

A low-quality, raw material technology, applied in the petroleum industry, processing hydrocarbon oil, hydrotreating process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

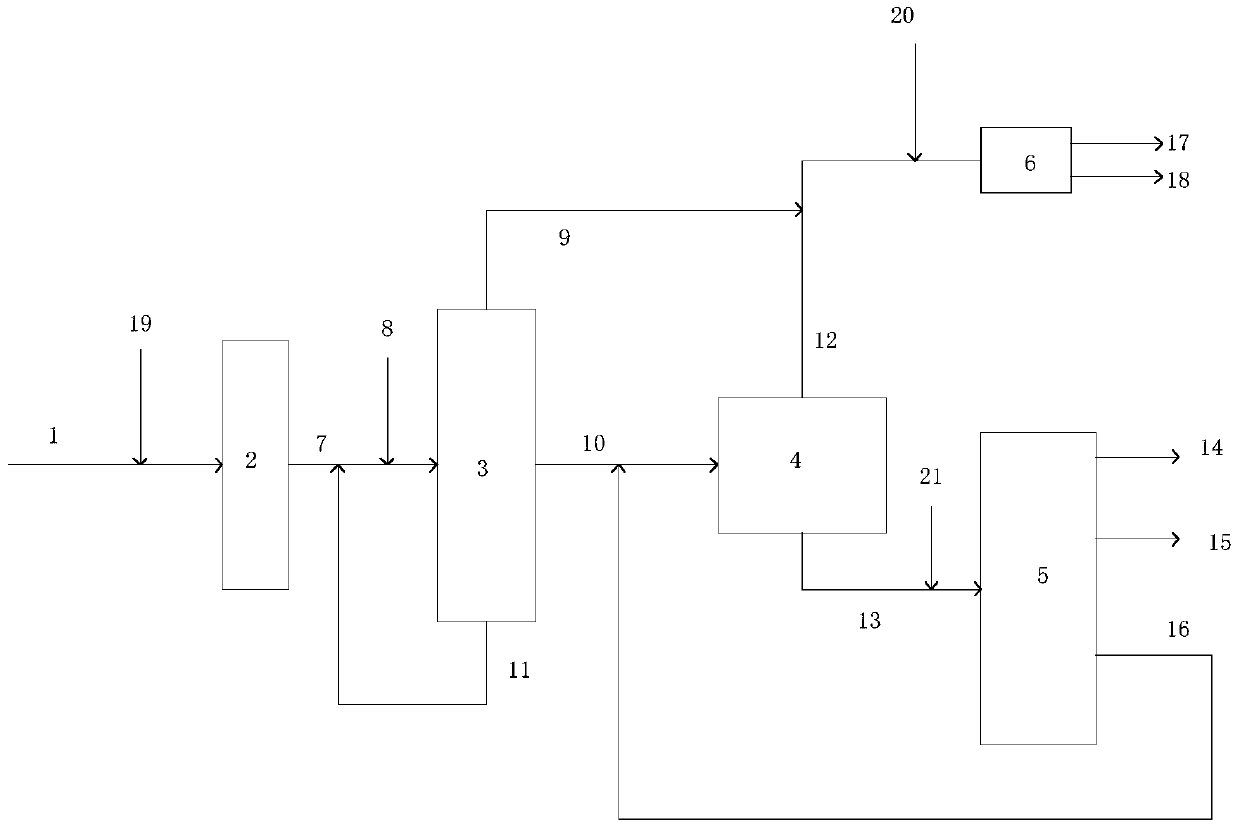

Method used

Image

Examples

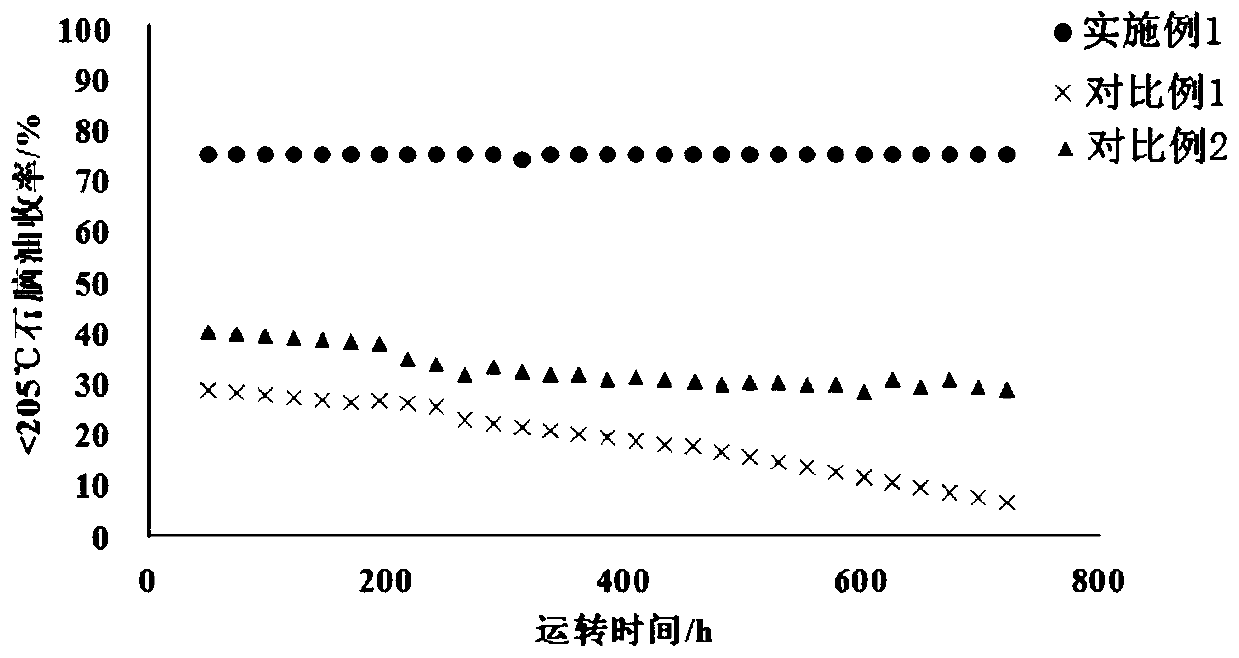

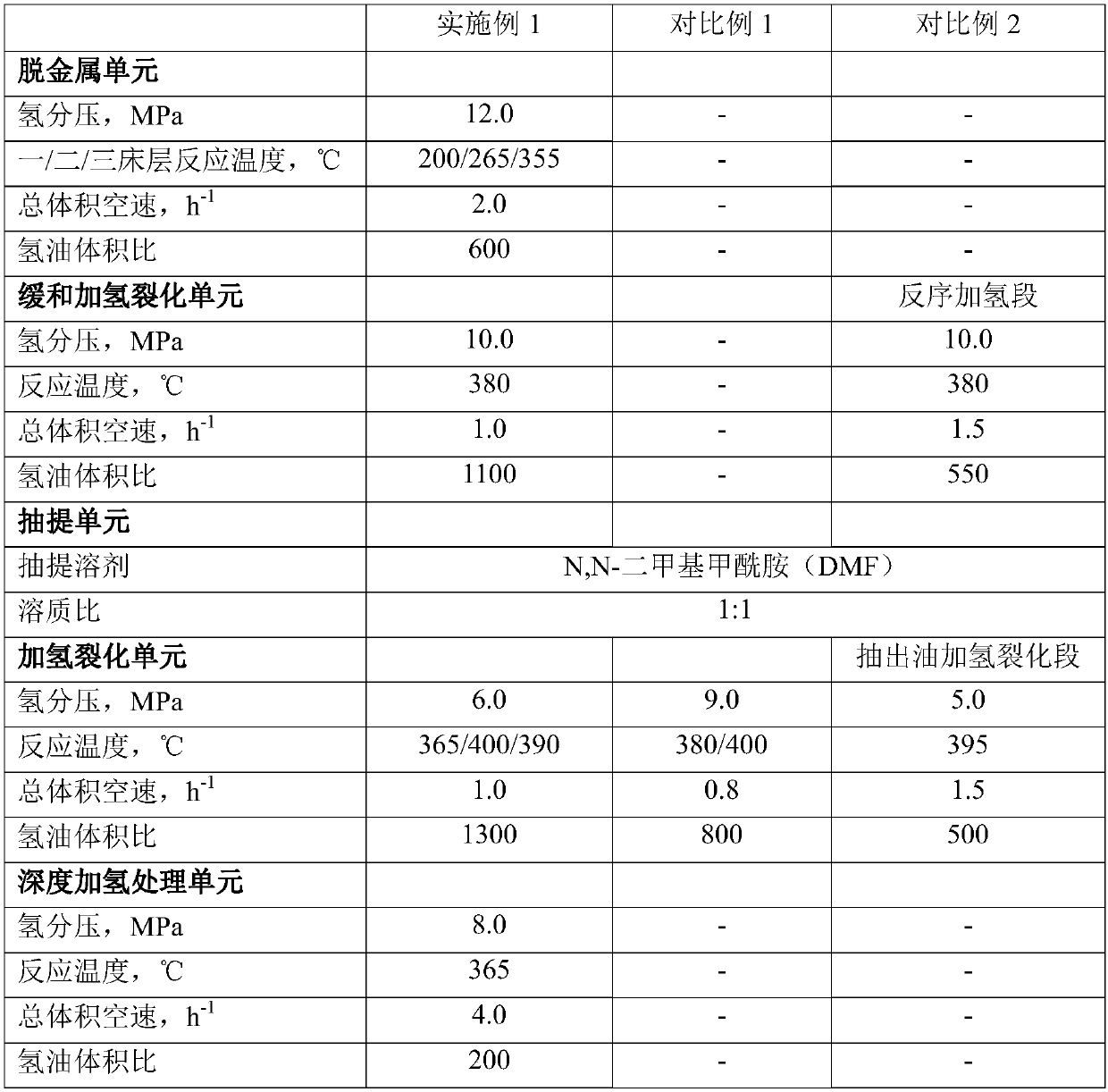

Embodiment 1

[0119] According to the method described in the present invention: after mixing the coal-based inferior raw material with hydrogen, introduce in turn containing 10RG-20, RG-30A, RG-30B, RG-1, large particle size RDM-35 (diameter is 2.5mm), small The demetallization unit of particle size RDM-35 (diameter is 1.1mm), large particle size RDM-35 (diameter is 2.5mm), small particle size RDM-35 (diameter is 1.1mm) and RN-32V reacts, wherein, The loading volume ratio of large particle size RDM-35 and small particle size RDM-35 in each stage of the demetallization unit is 1:2, and the RN-32V catalyst accounts for 12% of the total catalyst volume in the demetallization unit; The reaction product of the demetallization unit and the self-recycled tail oil from the mild hydrocracking unit are mixed with hydrogen and then introduced into the mild hydrocracking unit containing RN-32V and catalyst Φ in sequence, wherein the mild hydrocracking unit The loading volume ratio of the RN-32V and th...

Embodiment 2

[0134] This embodiment is carried out using the same process flow as in Example 1, the difference is that the RN-32V catalyst in the demetallization unit of this embodiment accounts for 15% of the total volume of the catalyst in the demetallization unit, and the demetallization catalyst adopts Three-stage circulation (big-small-big-small-big-small) is used for filling, and the filling volume ratio of large particle size RDM-35 and small particle size RDM-35 in each stage is 1:3, and The total volume of the demetallization catalyst is the same as in Example 1. Table 4 shows the main reaction conditions of the demetallization unit, mild hydrocracking unit, extraction unit, deep hydroprocessing unit and hydrocracking unit. Table 5 shows the yield and main properties of clean naphtha product, clean diesel product, light gasoline fraction and heavy gasoline fraction.

Embodiment 3

[0136] This embodiment is carried out using the same process flow as in Example 2, the difference is that the RN-32V catalyst in the demetallization unit of the present embodiment accounts for 8% of the total volume of the catalyst in the demetallization unit, and the demetallization catalyst adopts Two-stage circulation (big-small-big-small) is used for loading, the volume ratio of the large particle size RDM-35 and small particle size RDM-35 in each stage is 1:4, and the demetallization catalyst The total volume is the same as in Example 1. Table 4 shows the main reaction conditions of the demetallization unit, mild hydrocracking unit, extraction unit, deep hydroprocessing unit and hydrocracking unit. Table 5 shows the yield and main properties of clean naphtha product, clean diesel product, light gasoline fraction and heavy gasoline fraction.

[0137]

[0138] Table 4

[0139] table 5

[0140] The yield and properties of each fraction of the product

[0141]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com