Needle plate

A technology of needle plate and needle sheet, which is applied in deburring devices, textiles and papermaking, fiber processing, etc. It can solve the problems of affecting normal work, long needle changing time, and easy injury of people, so that it is not easy to accumulate deformation, The effect of saving needle changing time and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

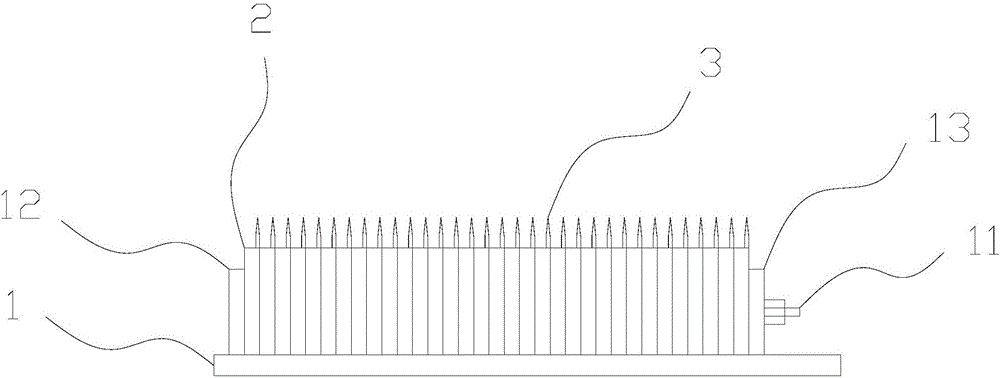

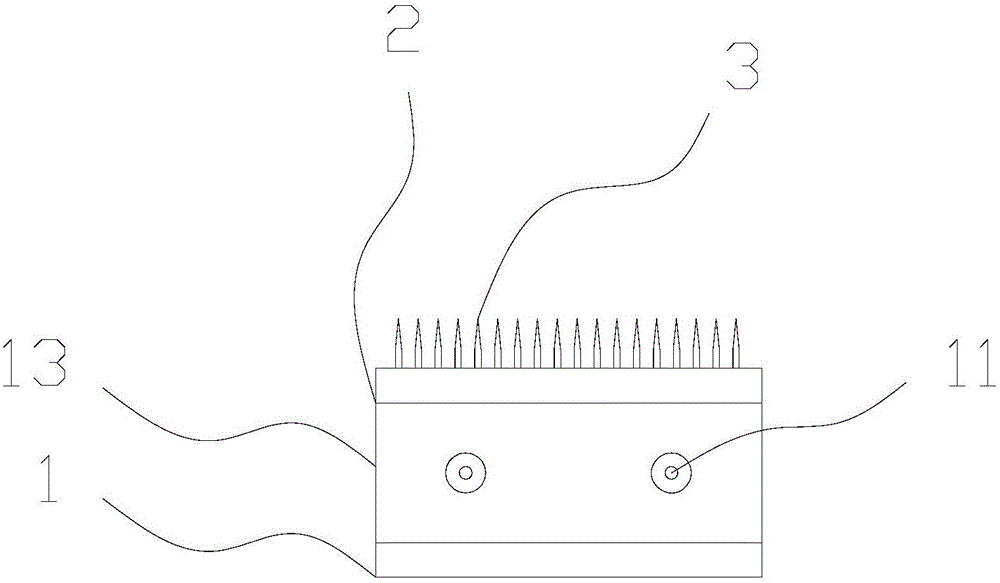

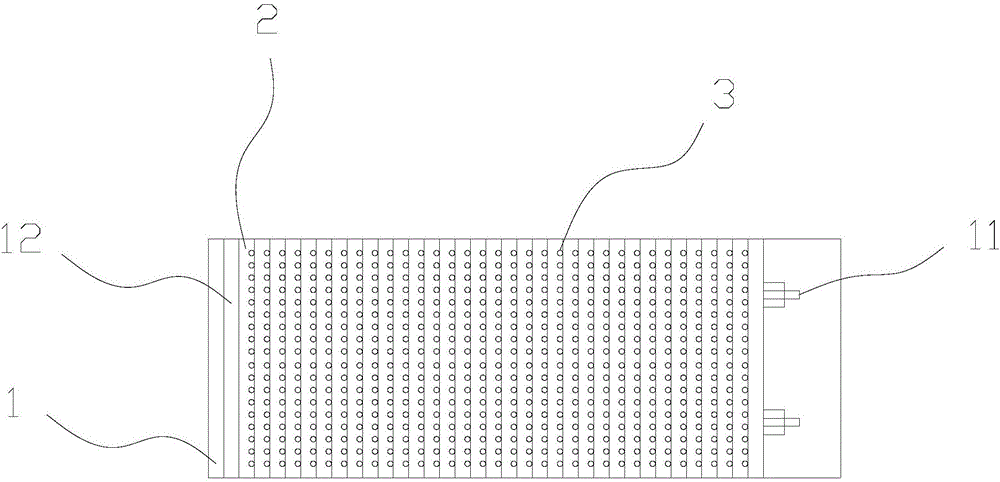

[0019] The present invention comprises a needle plate main body 1 and several needle sheets 2 arranged on the needle plate main body 1. The length direction of the needle plate main body 1 is provided with several connecting rods 11 with threaded ends, and the head ends of the connecting rods 11 are provided with There is a fixed positioning block 12, and a movable positioning block 2 13 is arranged at the end, and the positioning block 2 13 is fixed by a nut. The positioning block 12 and the positioning block 2 13 ensure that the needle piece can be fixed and will not damage the needle. piece;

[0020] One side of the needle sheet 2 is provided with several U-shaped needle placement grooves 21, and the depth and width of the needle placement grooves 21 in the longitudinal direction (in the present invention, the vertical direction from one side of the needle sheet t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap