Product protection circuit for achieving high voltage restraining during engine load dump

A technology for engine load and high pressure suppression, which is applied in the direction of engine starting, engine components, machines/engines, etc., to achieve the effect of small pressure drop and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

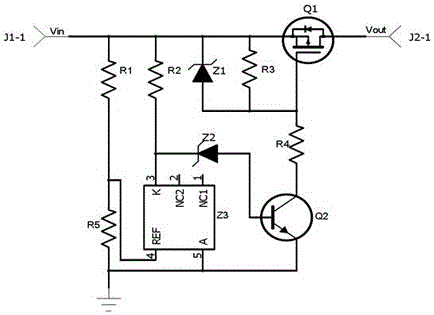

[0018] Such as figure 1 As mentioned above, the product protection circuit for realizing high-voltage suppression when the engine load suddenly drops disclosed in the present invention includes resistors R1-R5, voltage regulator tubes Z1-Z2, voltage reference source TL431, PMOS transistor Q1 and transistor Q2, wherein TL431 is composed of Z3 Mark, the source of the PMOS transistor Q1 is connected to the power input terminal Vin, the drain is used as the power output terminal Vout, and the gate is grounded through the resistor R4 and the transistor Q2 in turn; the resistors R1 and R5 are connected in series between Vin and the ground to form a voltage dividing sampling circuit , the sampling voltage output is connected to the REF terminal of TL431, the anode of TL431 is grounded, the cathode is respectively connected to Vin through resistor R2, and the base of transistor Q2 is connected through regulator Z2, and the power input terminal Vin is also connected through parallel reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com