A high-temperature water sprayer for spraying water in engine cylinder

A technology for engine cylinders and sprinklers, applied to engine components, machines/engines, mechanical equipment, etc., can solve the problems of sprinklers not working properly, poor thermal stability, needle valve sticking, etc., and achieve long-term stability work, improved reliability, and high cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

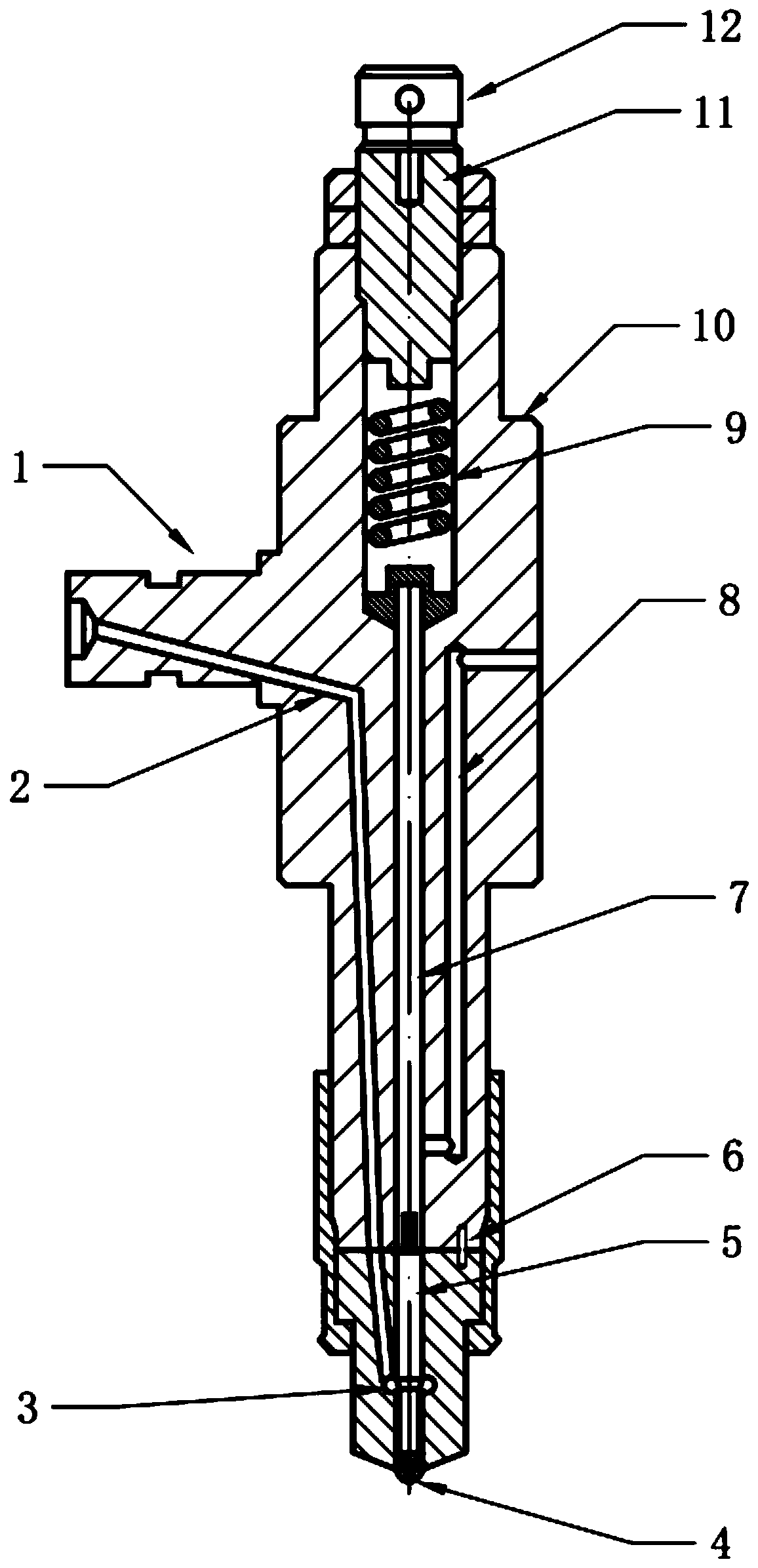

[0018] A high-temperature sprinkler for spraying water in the engine cylinder, such as figure 1 As shown, it includes a return pipe joint 12, a pressure regulating screw 11, a pressure regulating spring 9, a push rod 7, a sprinkler body 10, a needle valve 5, a positioning pin 6, a water inlet pipe joint 1, a water inlet pipe 2, and a cooling water inlet pipe 8. High-temperature and high-pressure water flows into the water inlet pipe 2 through the water inlet pipe joint 1 and enters the pressure chamber 3. The water pressure acts on the pressure-bearing cone surface of the needle valve 5 to generate an upward thrust. The adjusting screw 11 can adjust the pre-tightening force to control the When the thrust exceeds the pre-tightening force of the pressure regulating spring 9, the needle valve rises and the nozzle hole 4 is opened, and high-temperature water is sprayed from the nozzle hole 4. The cooling water introduction pipe 8 is connected to the gap between the push rod and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com