Flow control electromagnetic valve

A flow control and solenoid valve technology, applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of unsuitable macro-adjustable working conditions, poor reliability, complex structure, etc., and achieve simple structure, stable flow, and simple control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

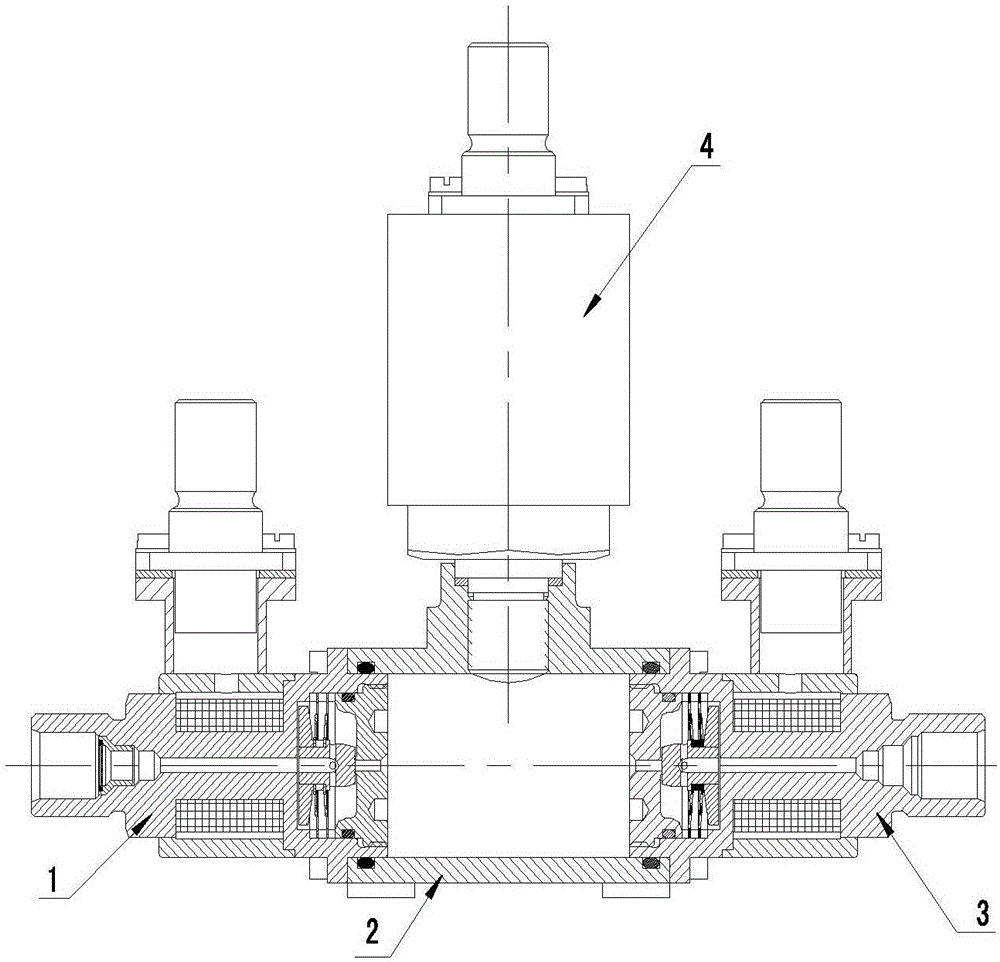

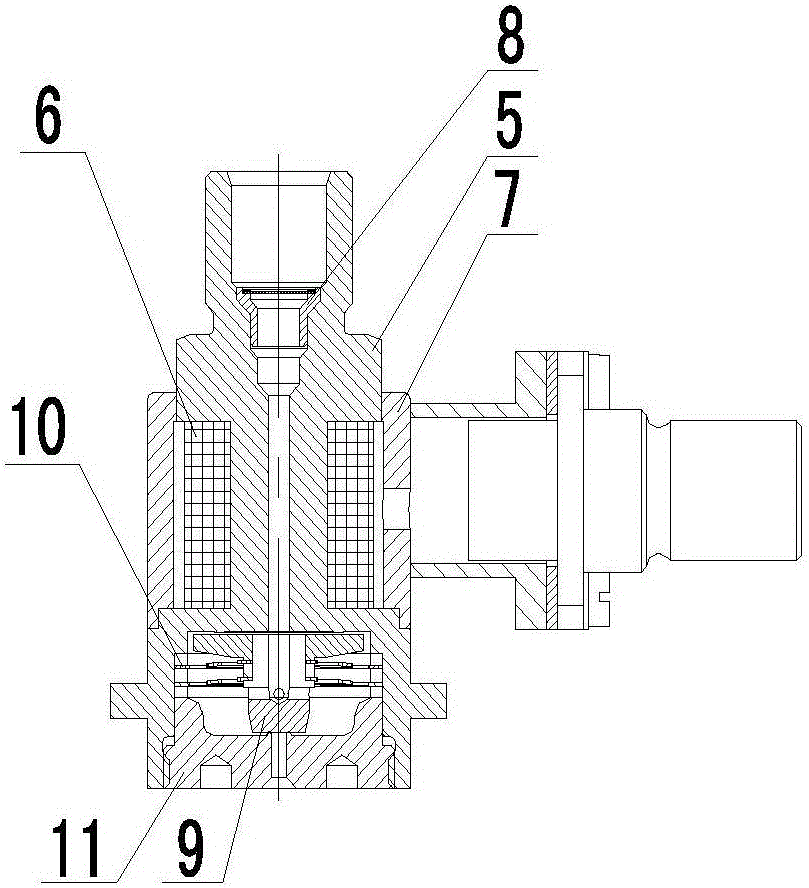

[0016] like figure 1 As shown, the present invention provides a flow control solenoid valve, including a first frictionless solenoid valve 1 , a cavity base 2 , a second frictionless solenoid valve 3 , and a pressure sensor 4 . The first frictionless solenoid valve 1 and the second frictionless solenoid valve 3 are symmetrically installed on both sides of the cavity base 2 through a square flange. When work is required, the first frictionless solenoid valve 1 is energized first, and the valve core 9 overcomes the medium force and frictional force movement, open the medium inlet, and the upstream medium pressurizes the cavity base 2; then the first frictionless solenoid valve 1 is de-energized, the medium inlet is closed, the second frictionless solenoid valve 3 is energized, the medium outlet is opened, and the cavity The medium in the medium is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com