Patents

Literature

35results about How to "Avoid sliding wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

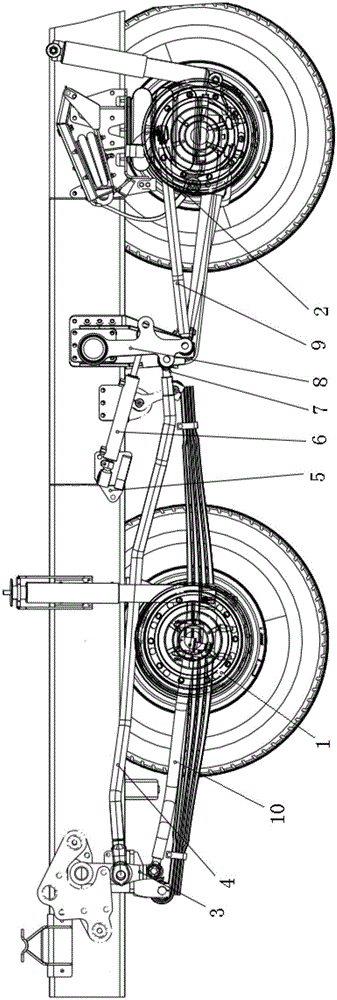

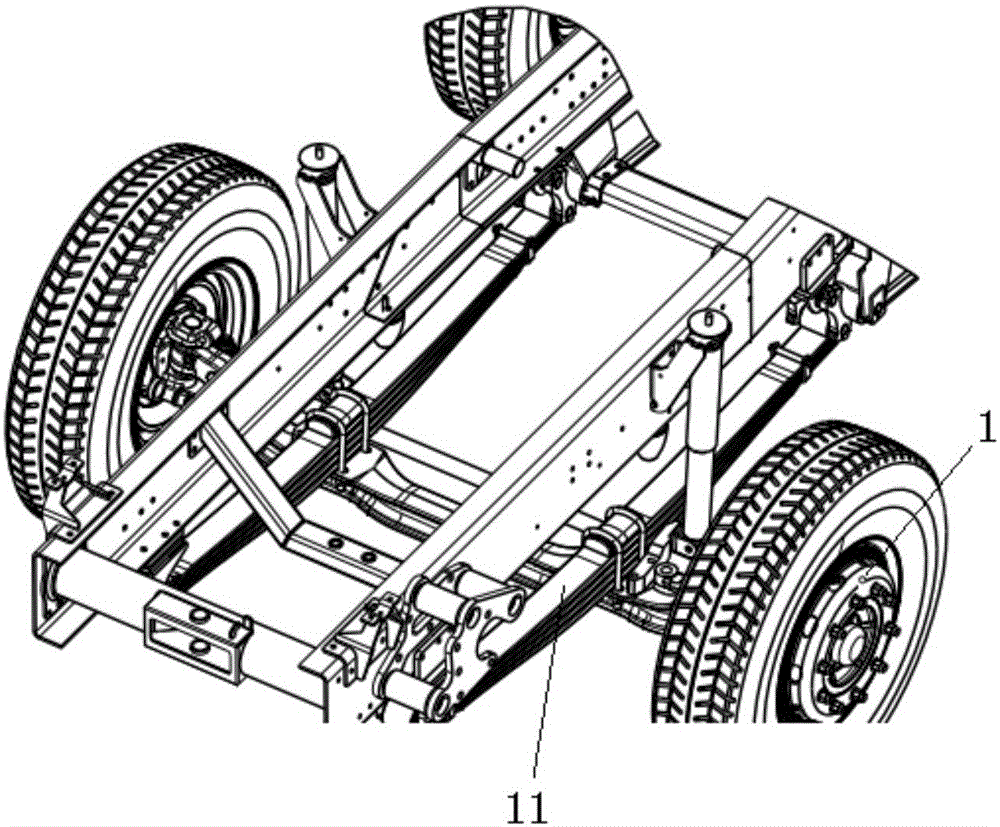

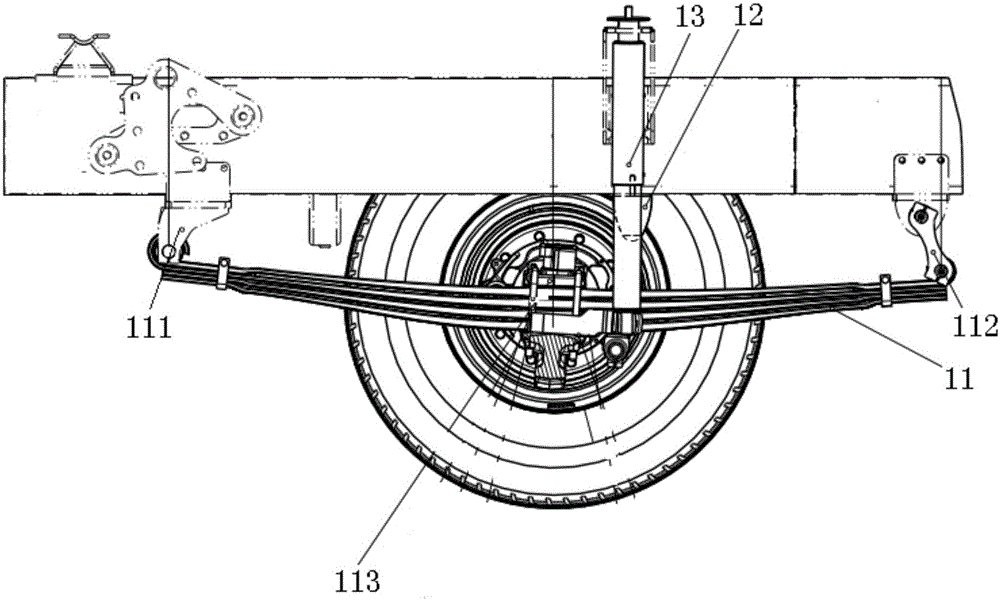

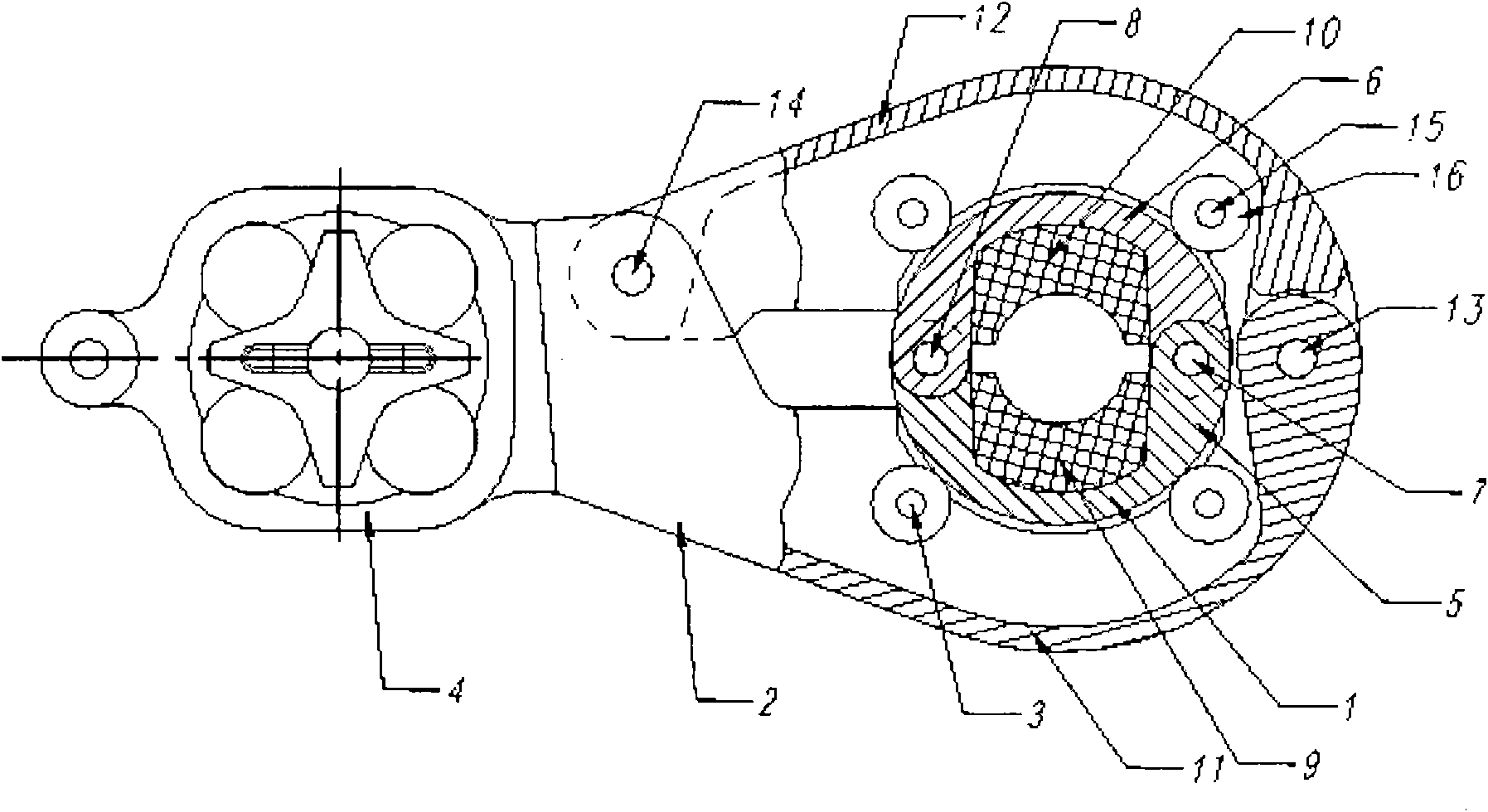

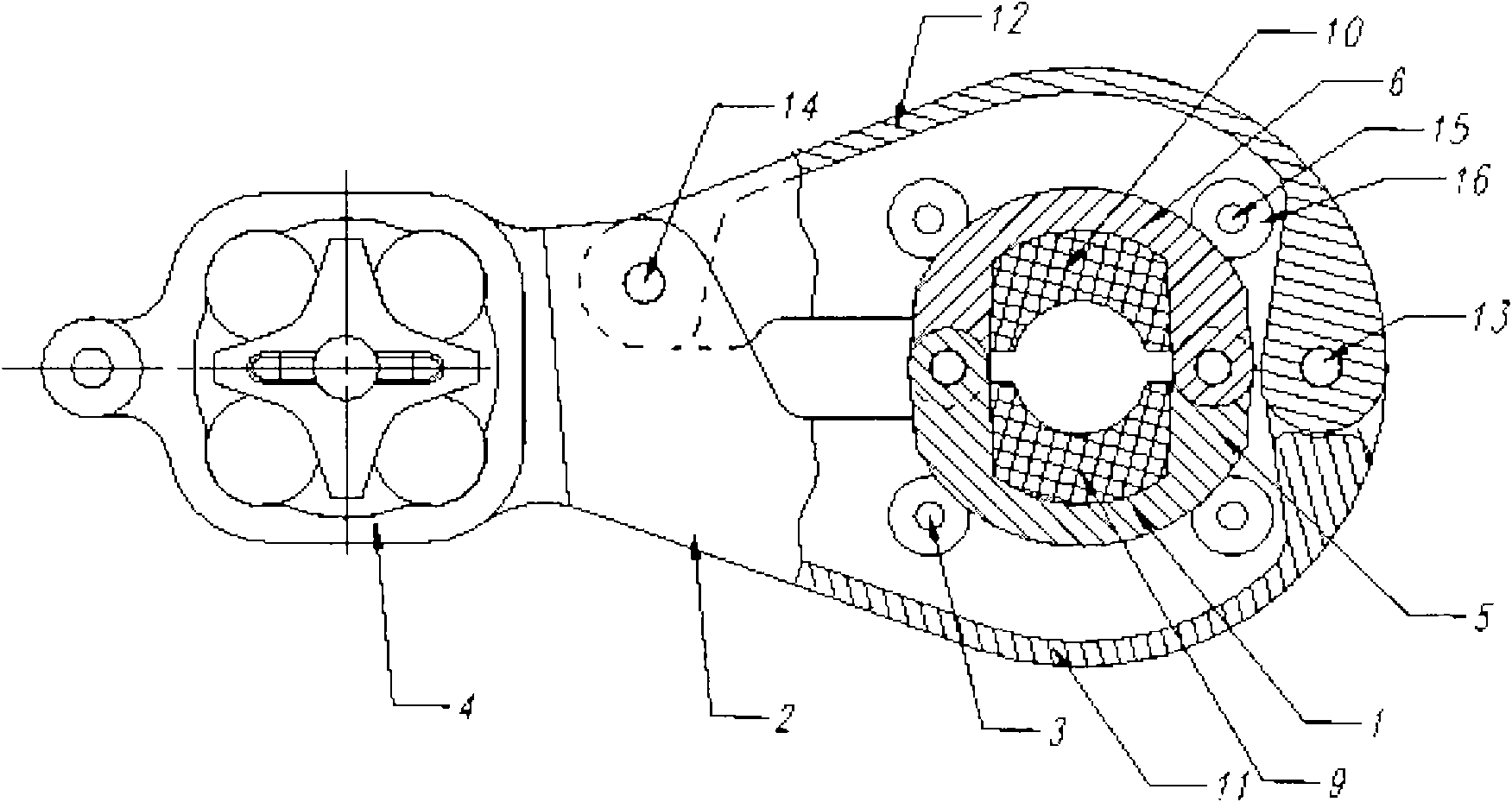

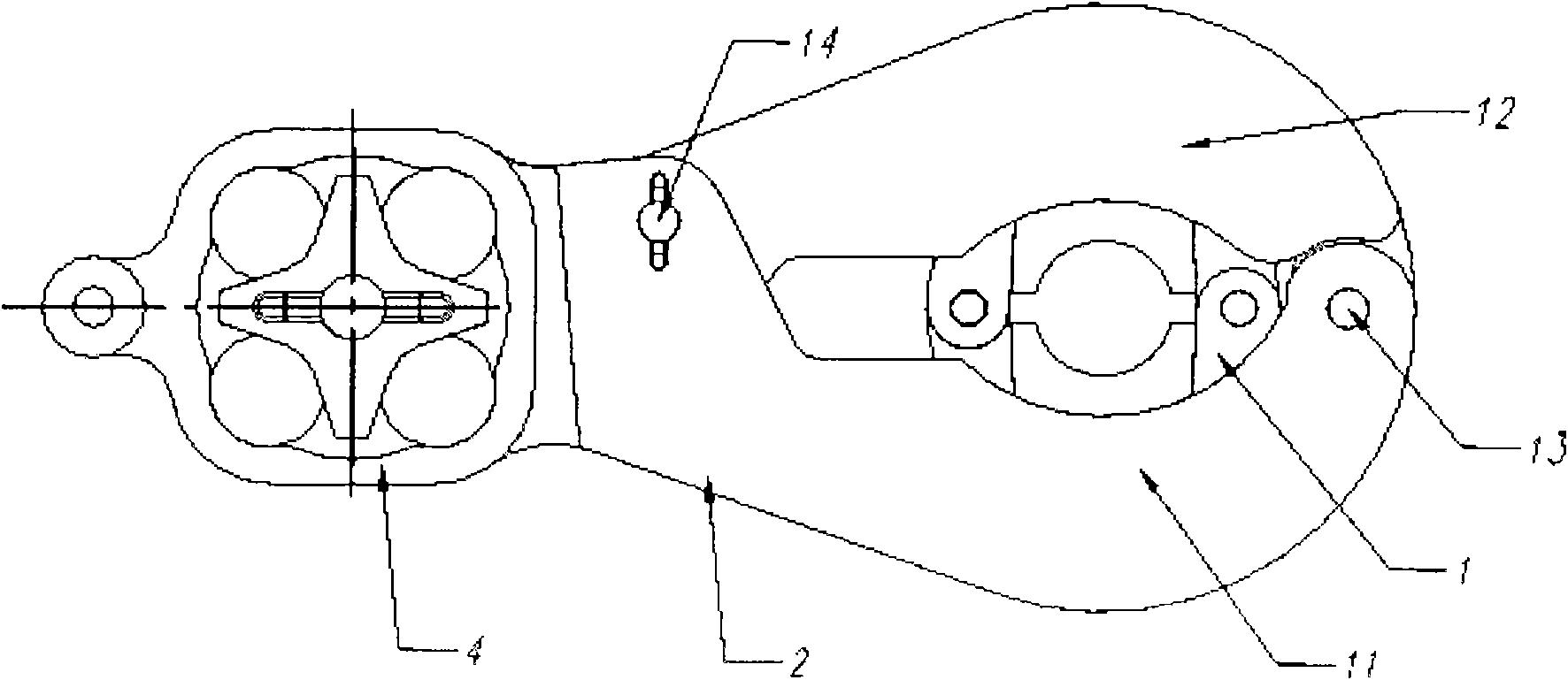

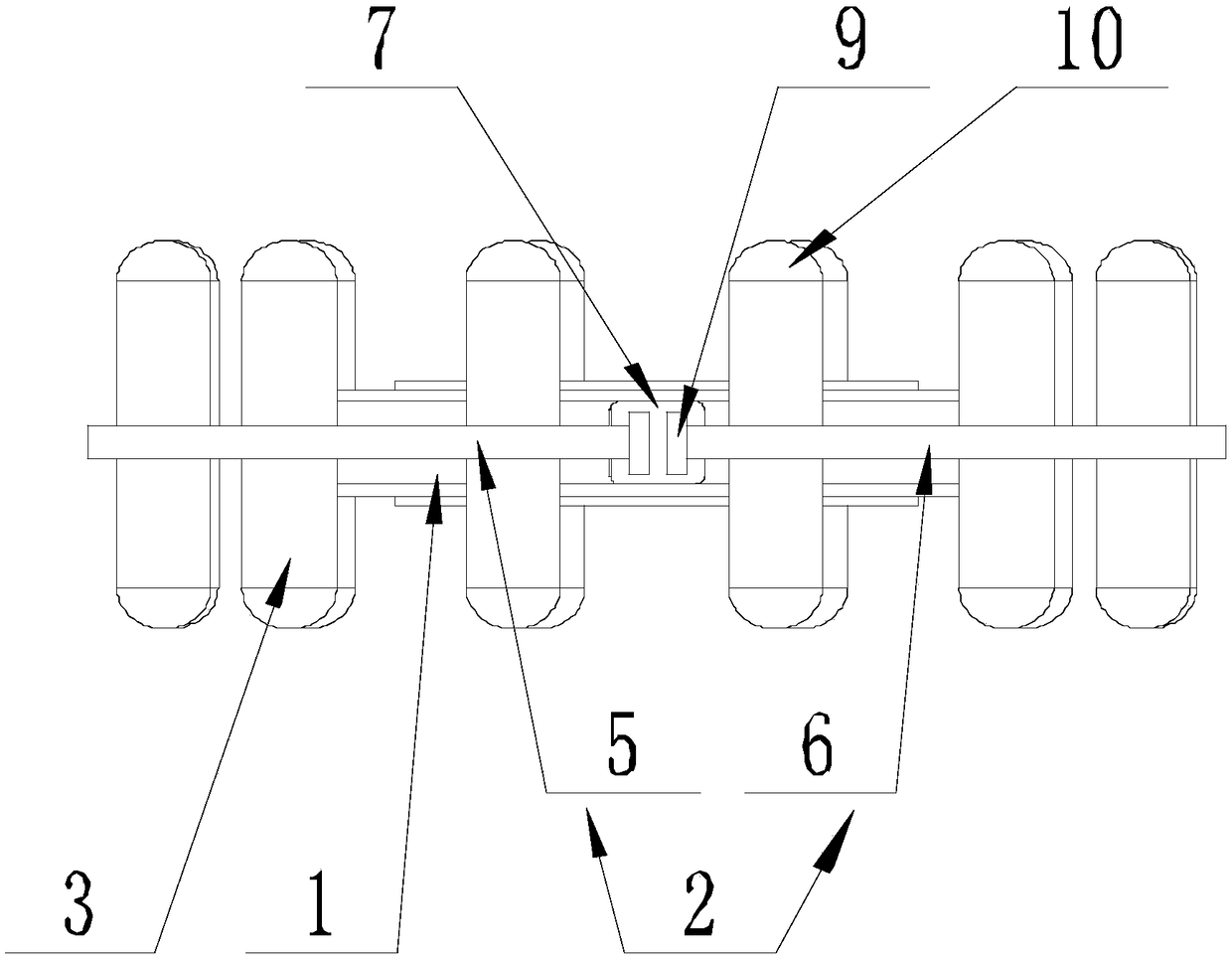

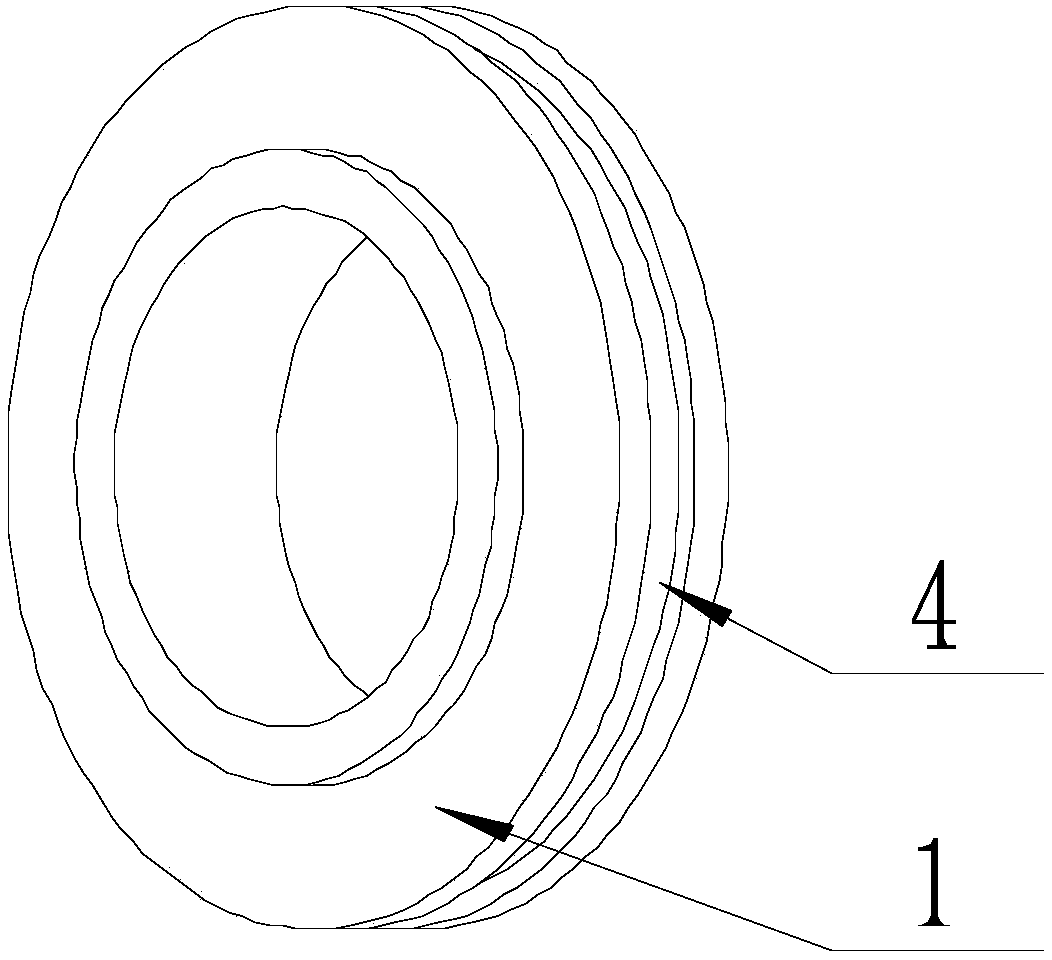

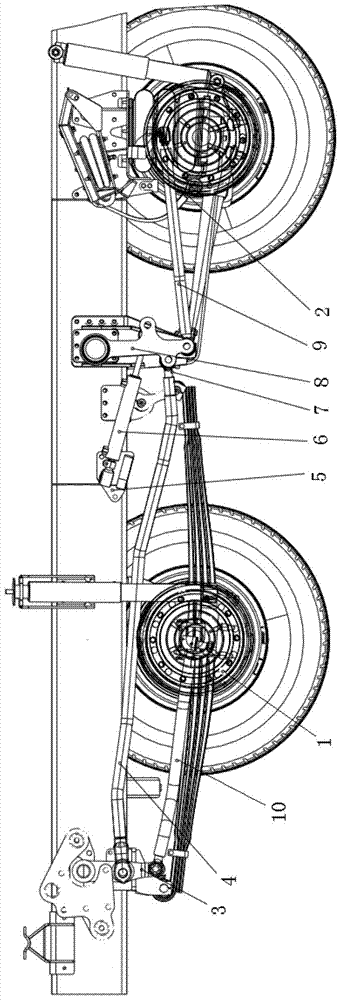

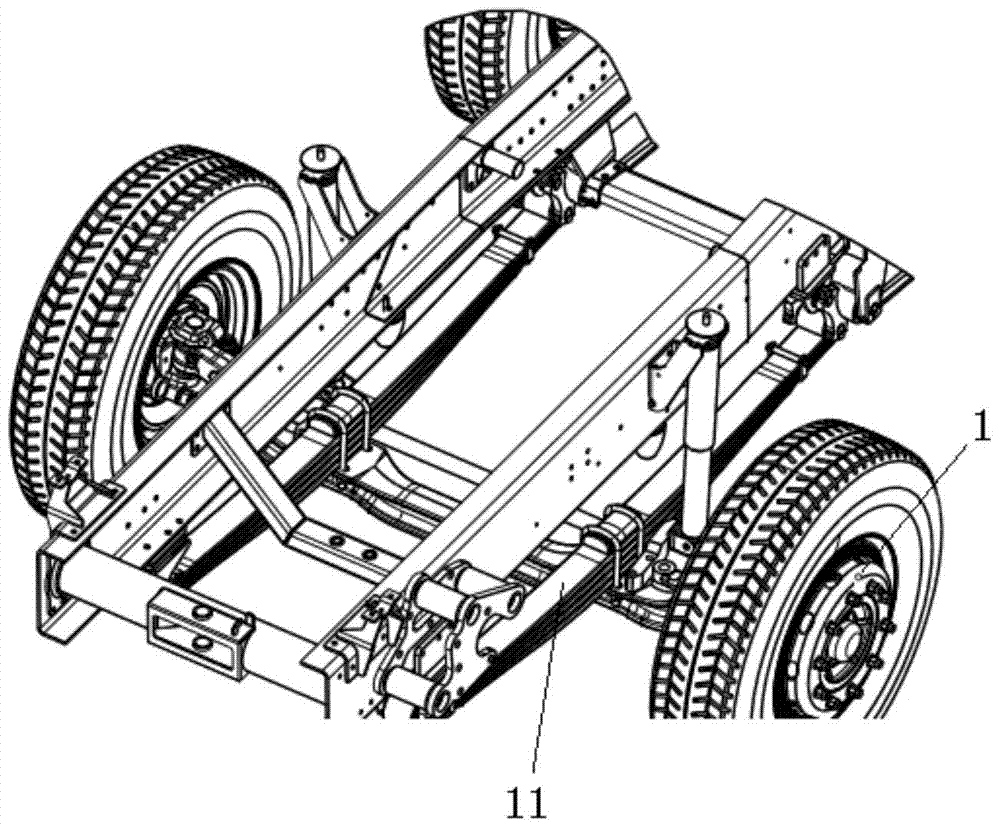

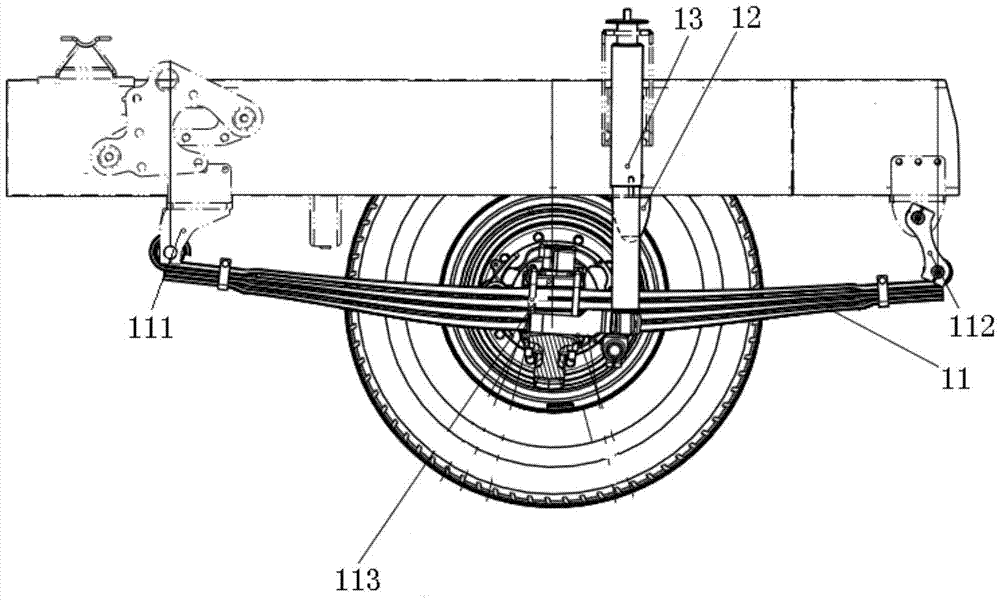

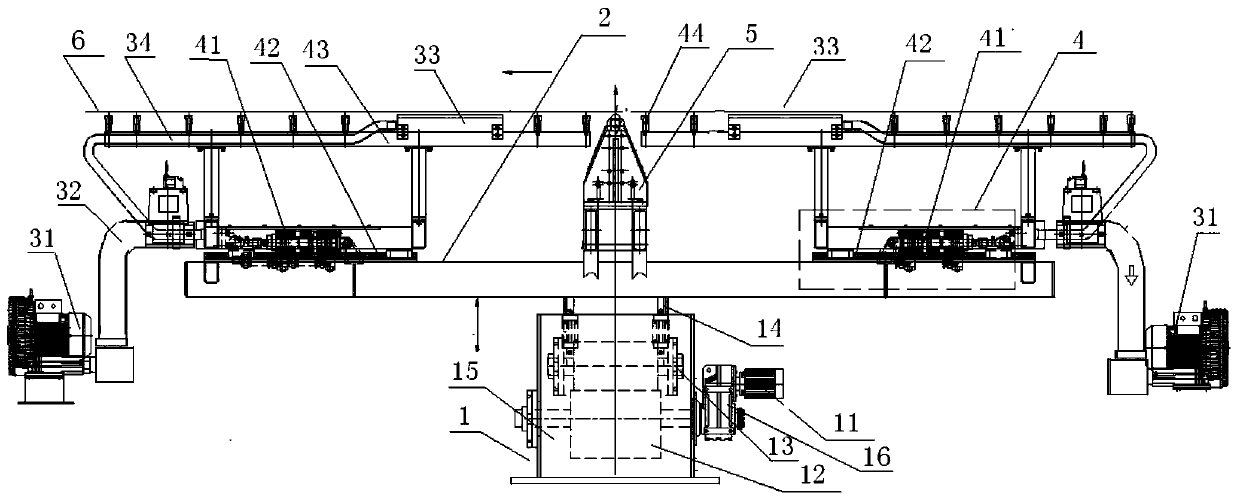

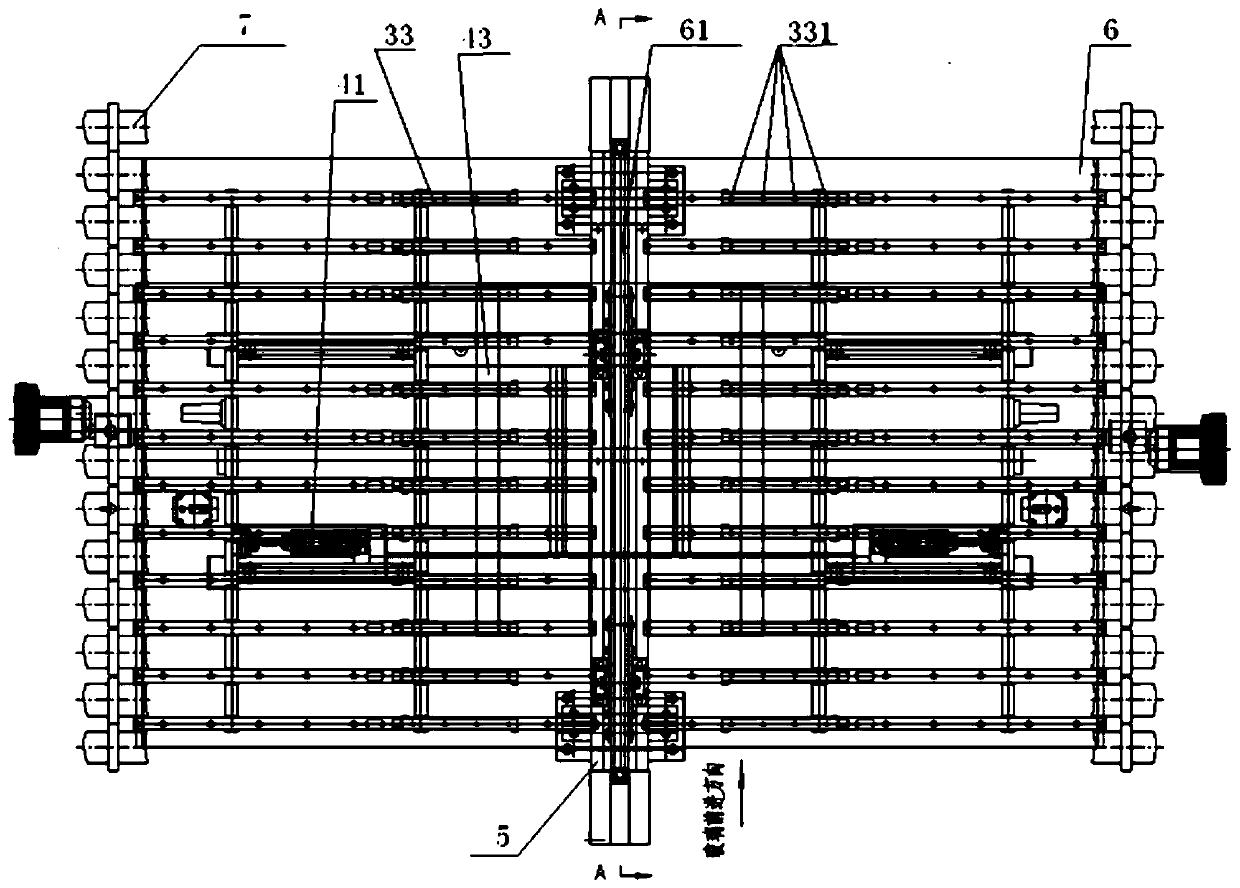

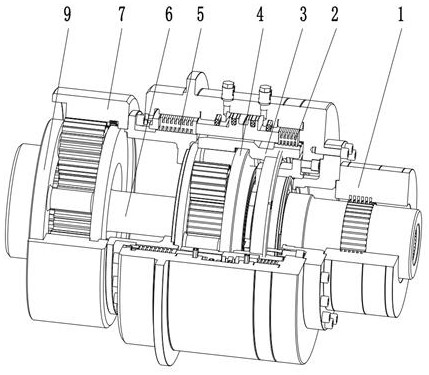

Double-front-axle structure with lifting axle for heavy truck

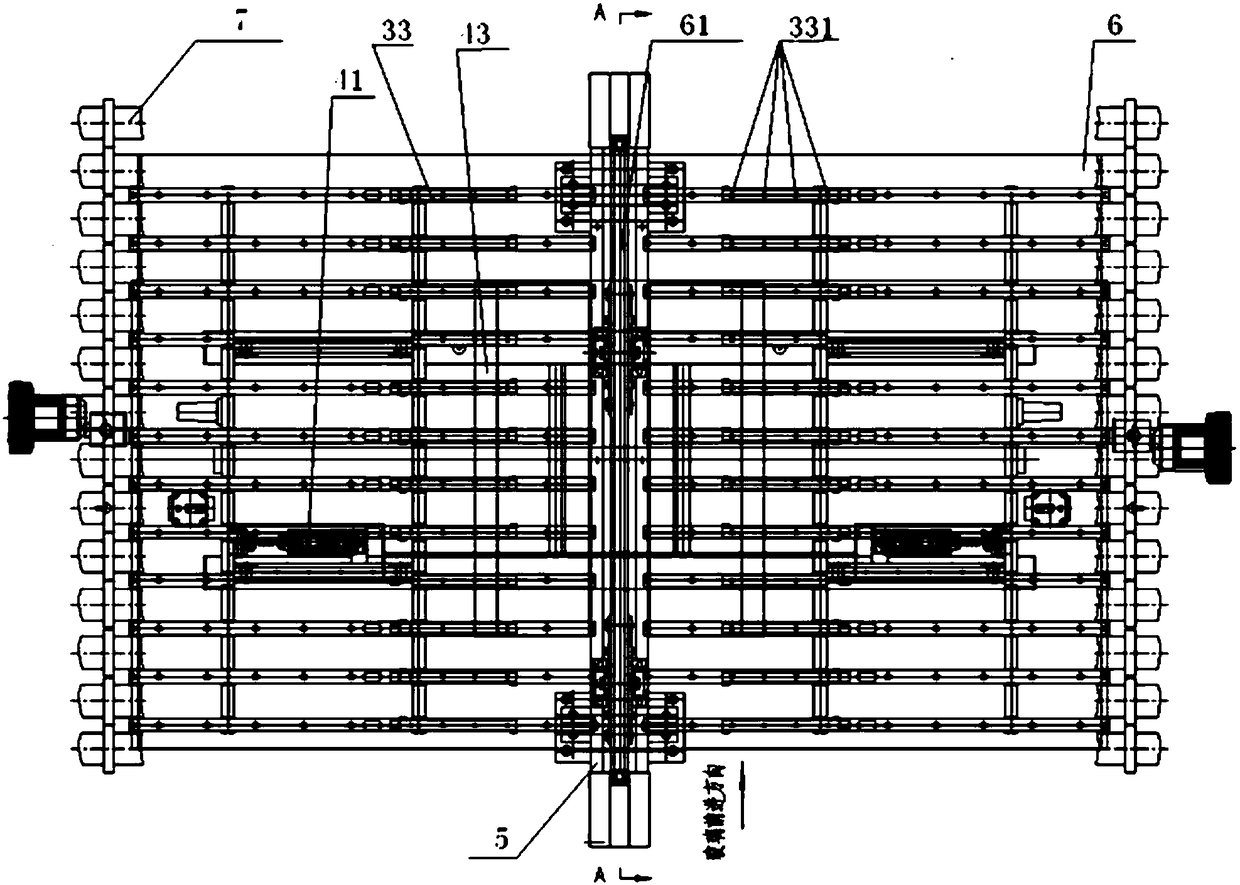

The invention relates to a double-front-axle structure with a lifting axle for a heavy truck. The double-front-axle structure comprises a first front axle, a second front axle, a first front-axle steering pull rod assembly, steering-machine steering knuckle arms, first front-axle steel plate springs, second front-axle lifting air bags, air-bag springs, second front-axle lifting brackets, second front-axle lifting cables and second front-axle steel plate springs. According to the double-front-axle structure disclosed by the invention, through the structural design of the second front-axle lifting air bags, the second front-axle lifting brackets and the second front-axle lifting cables, and through the lifting of the second front-axle lifting air bags, second front-axle tires are separated from a road surface, and the abrasion of the tires is reduced. When the heavy truck turns, the first front axle and the second front axle simultaneously turn, so that the phenomenon that because a second front axle cannot turn, sliding abrasion is caused is avoided. Through the structural design of the first front-axle steel plate springs, the second front-axle steel plate springs and the air-bag springs, the dead weight of the vehicle is effectively reduced.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

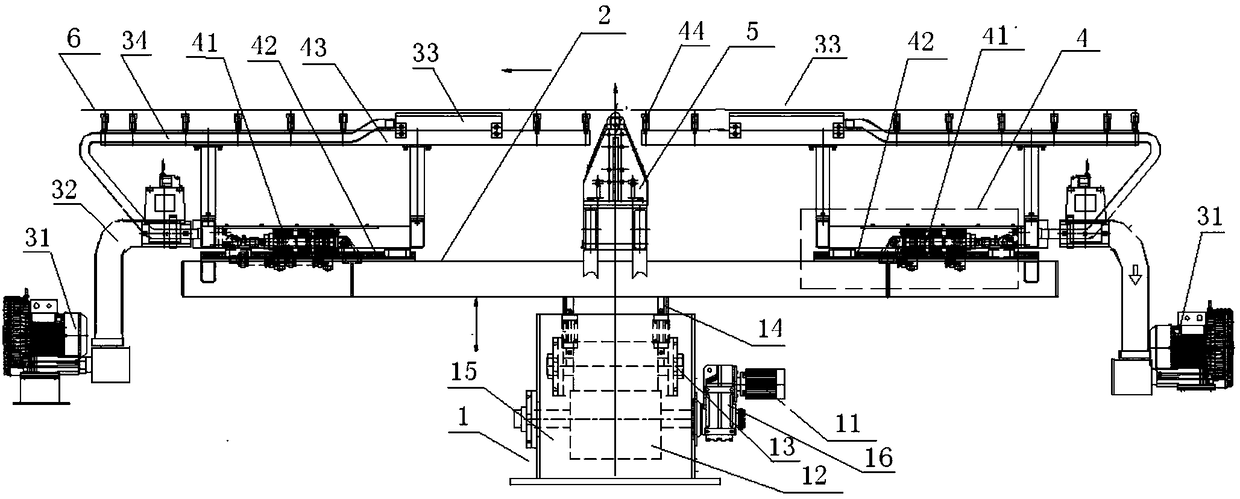

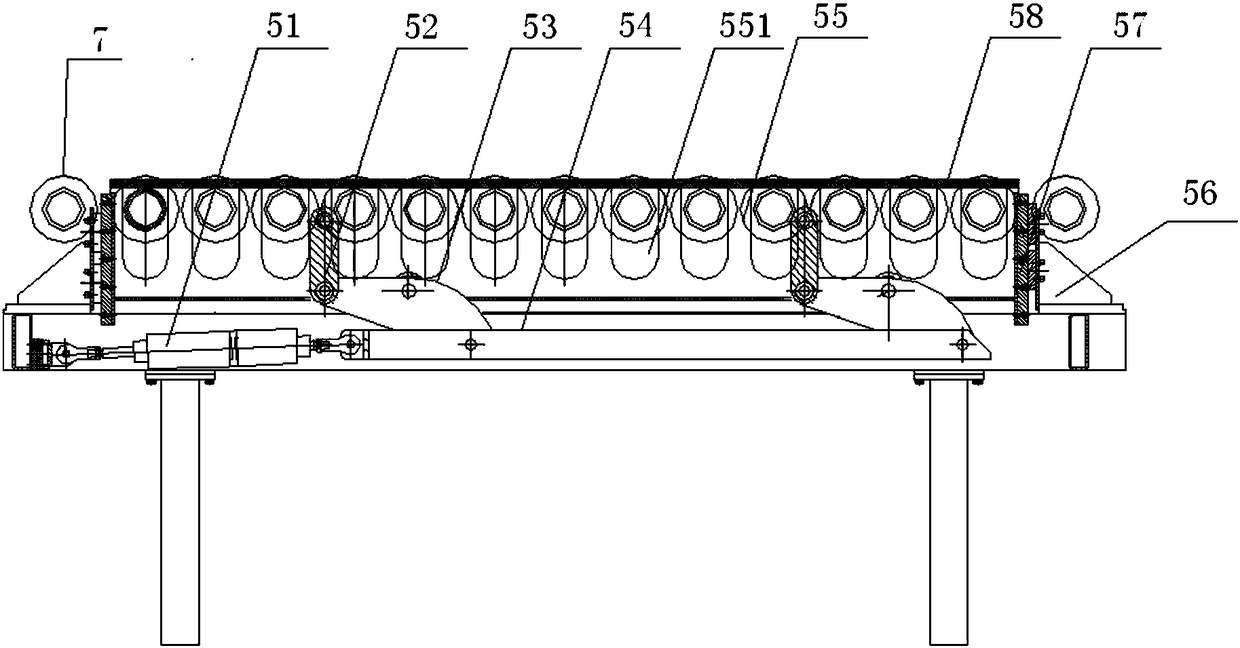

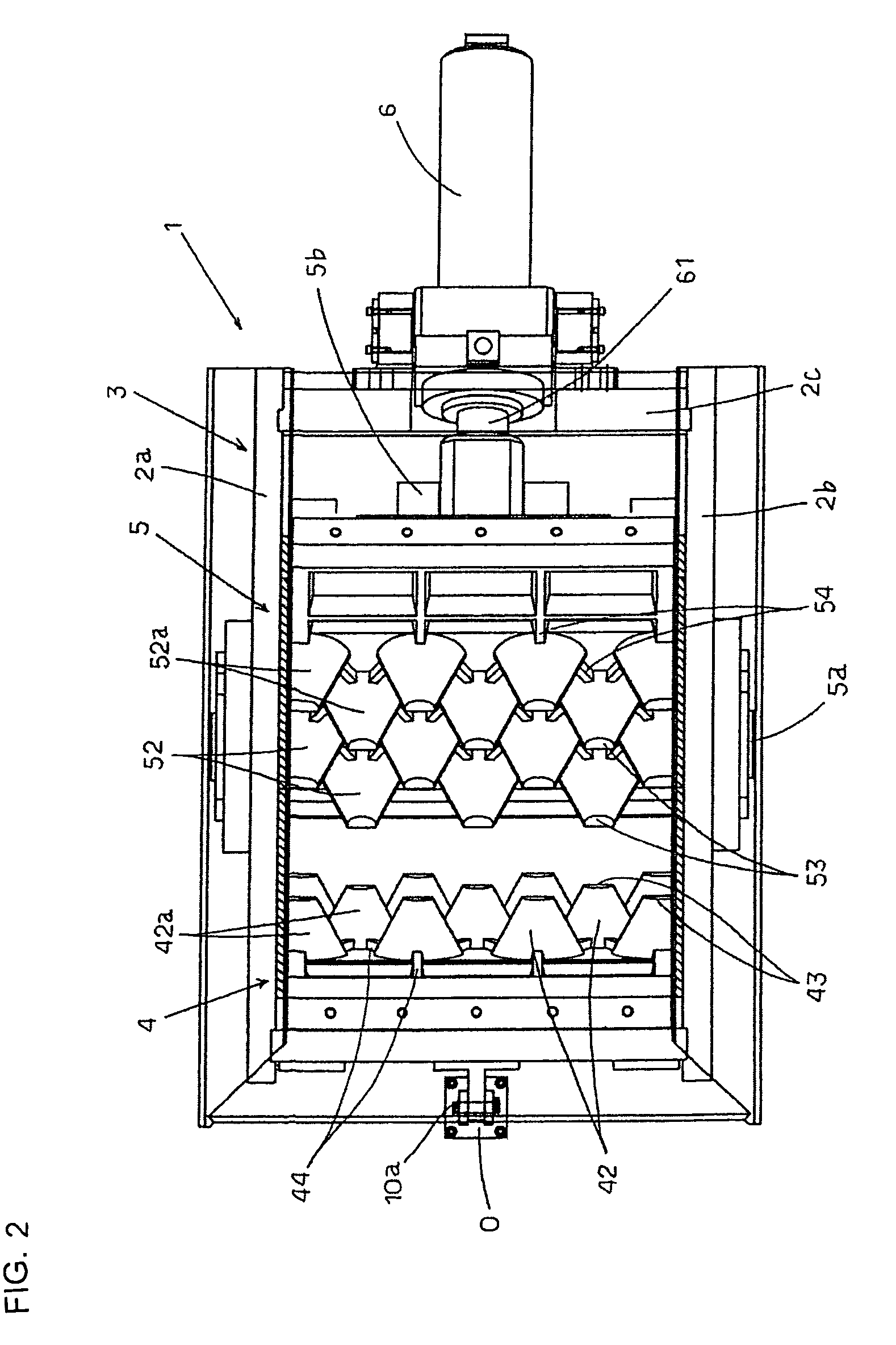

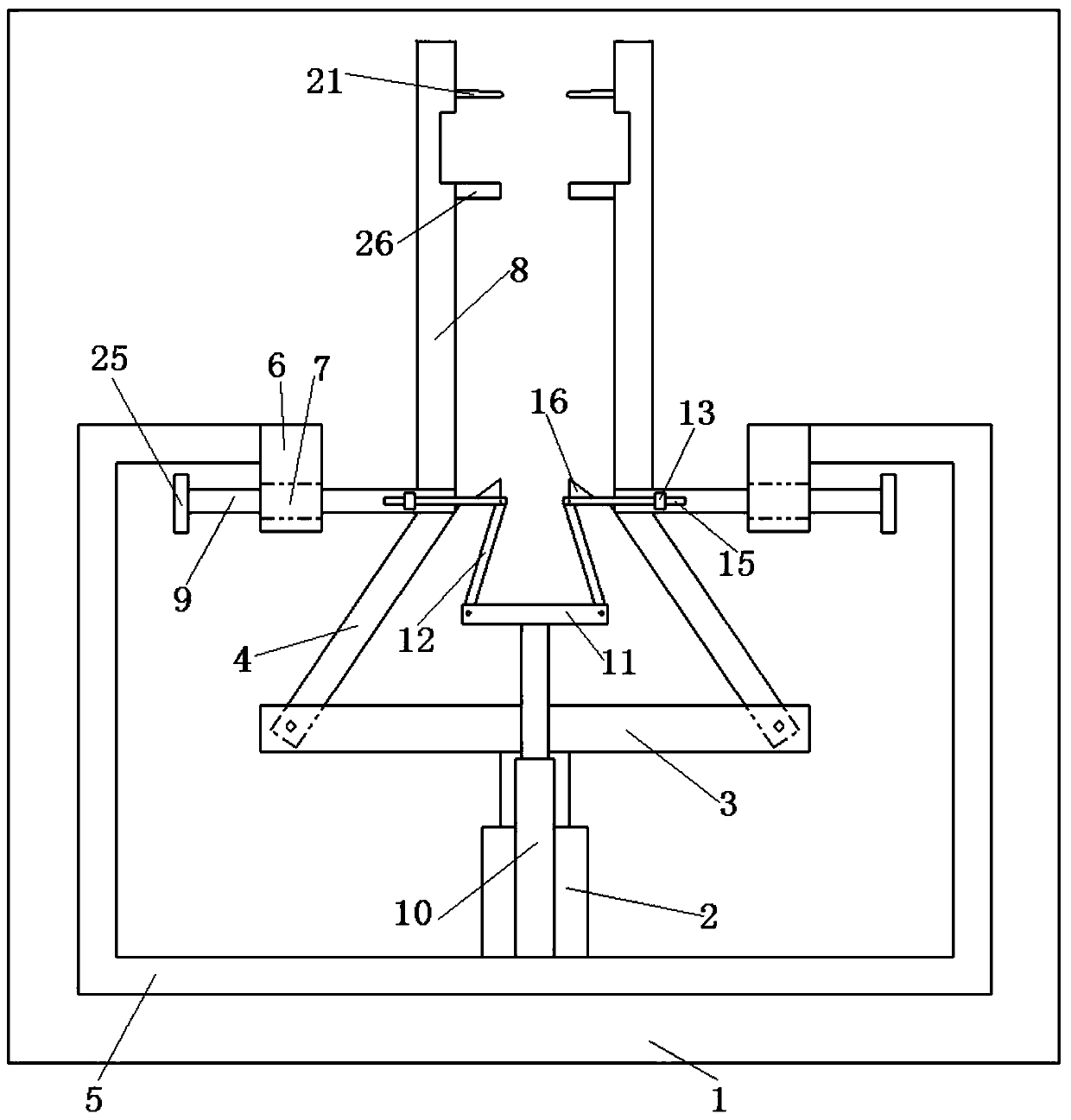

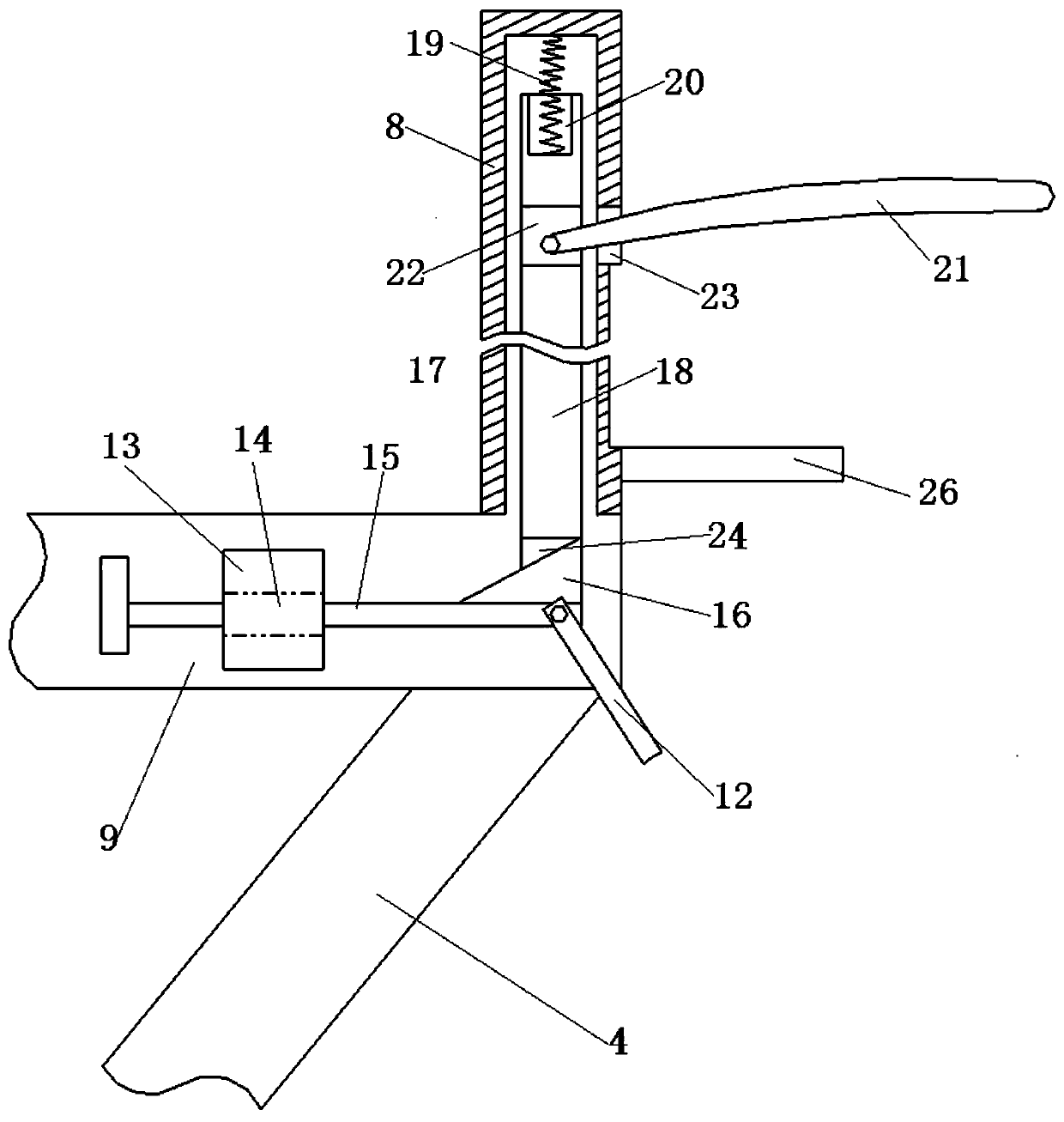

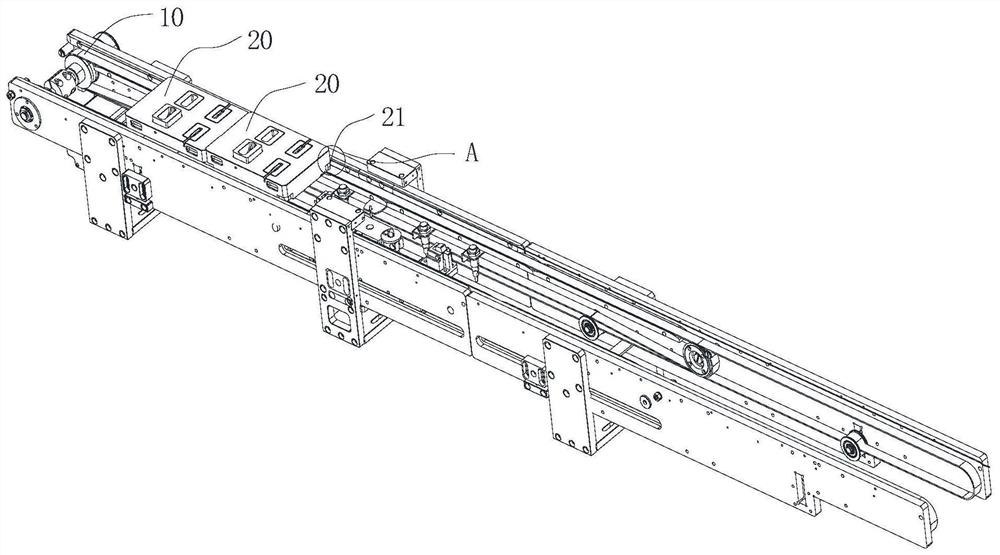

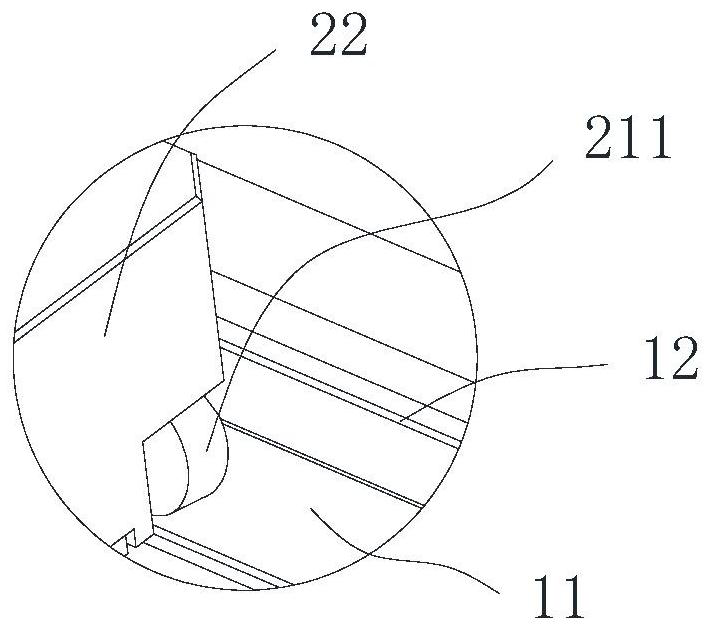

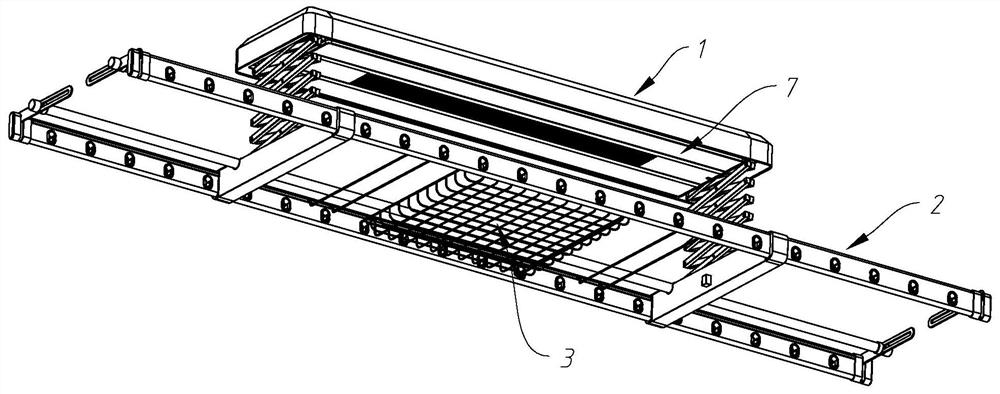

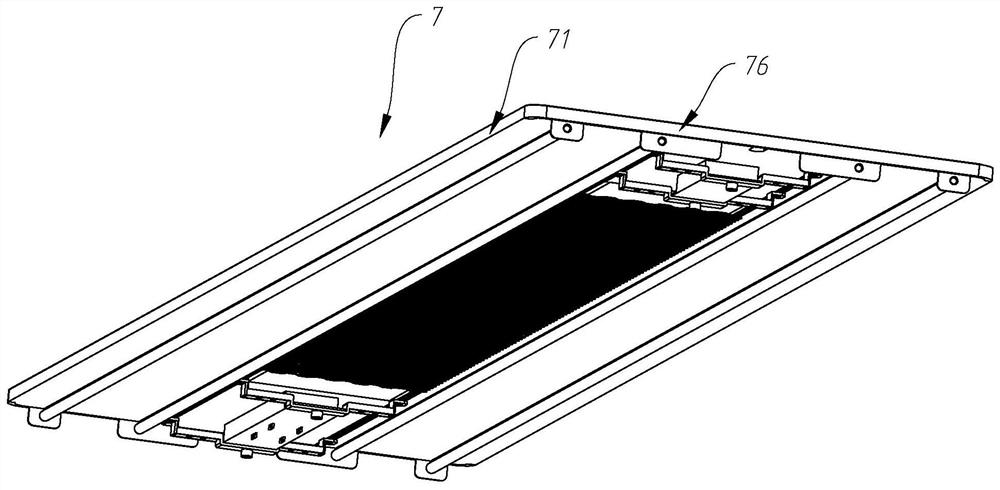

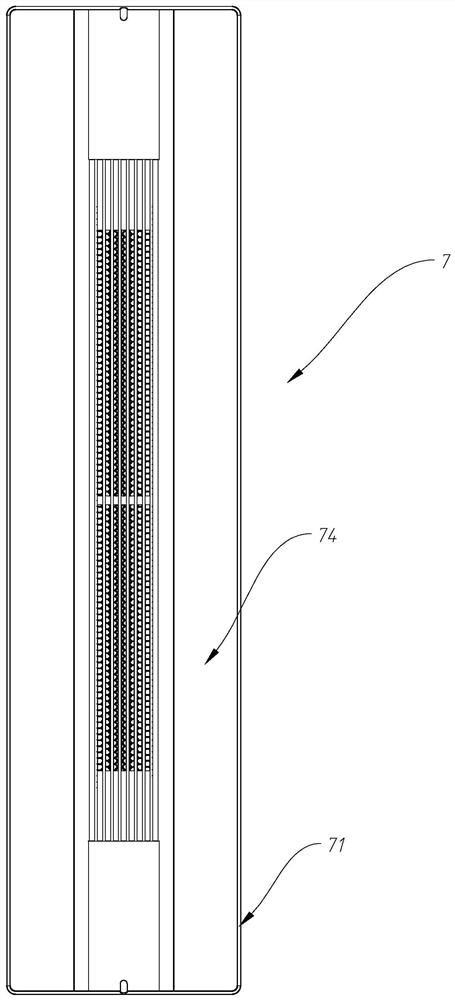

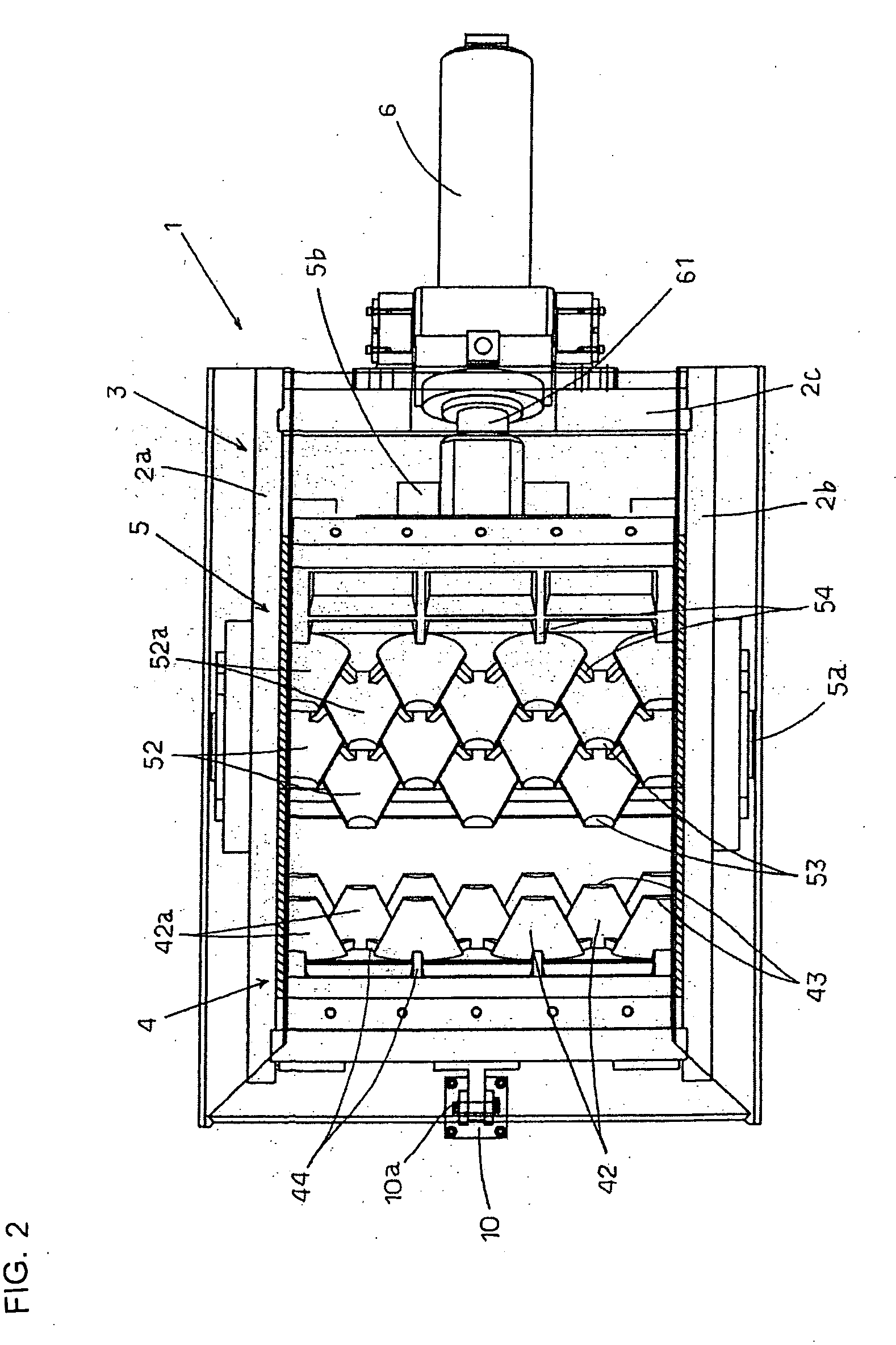

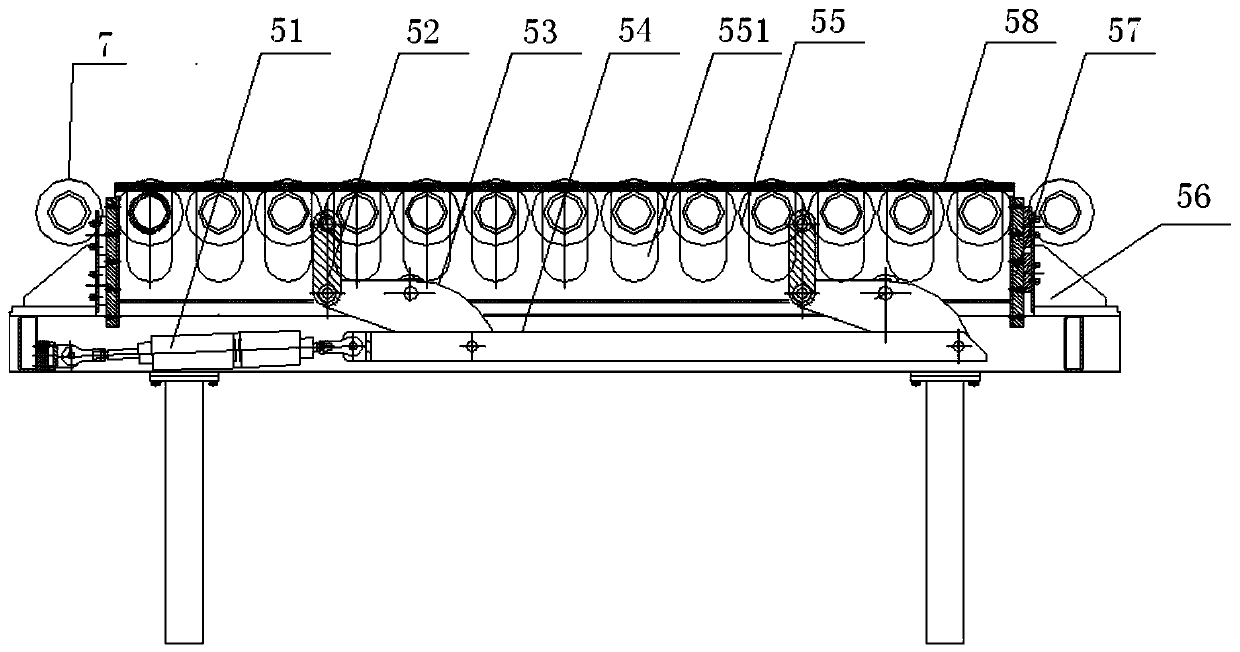

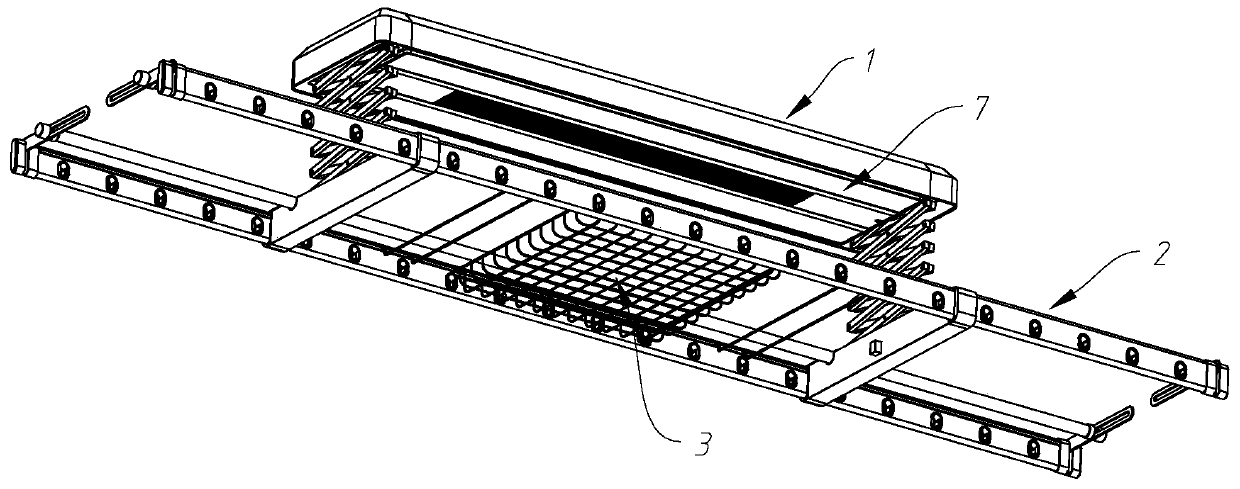

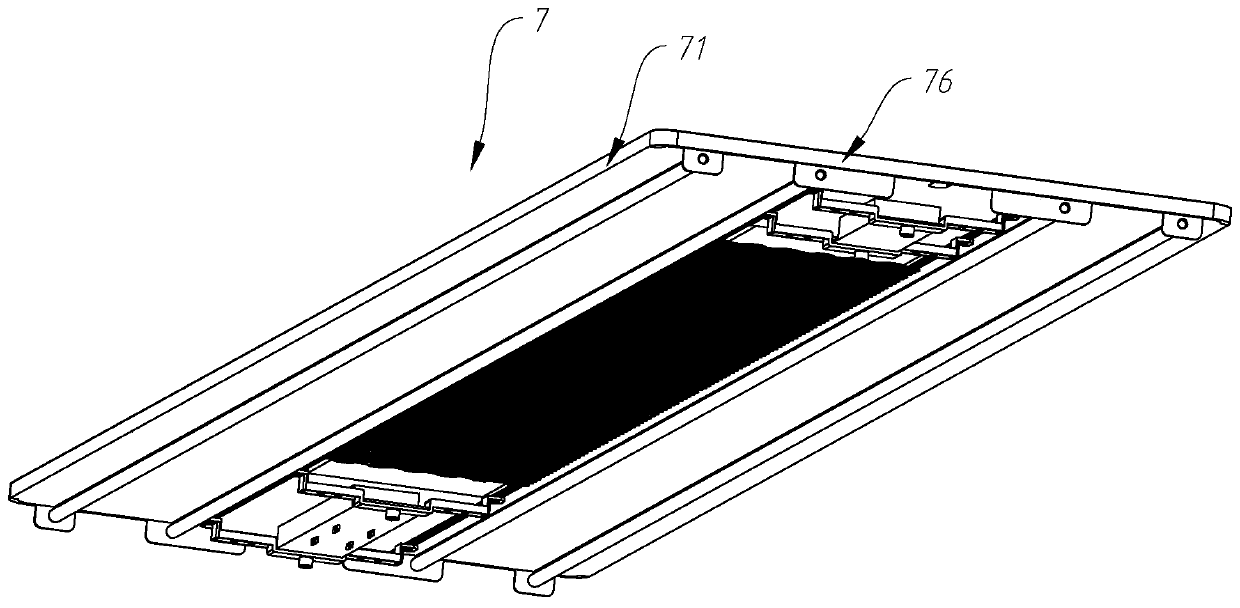

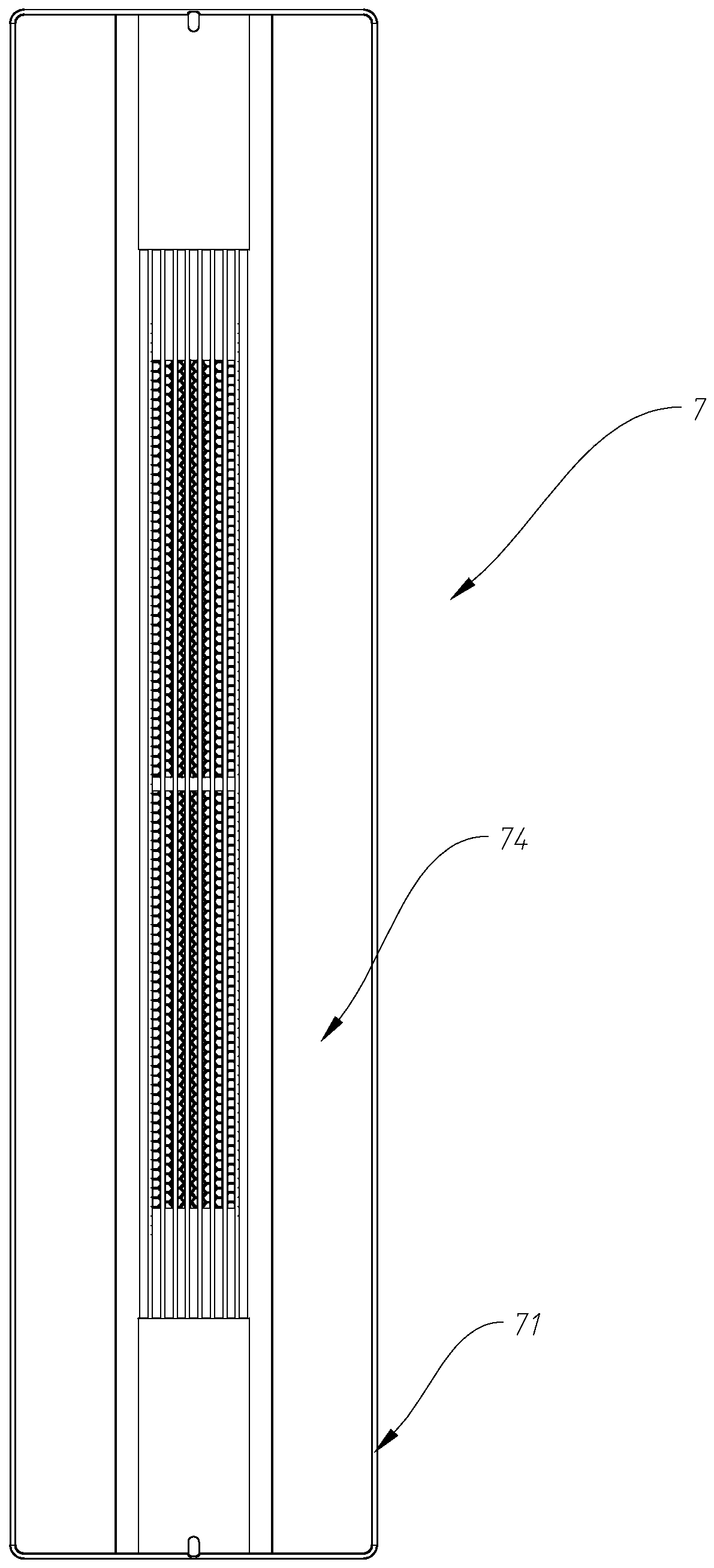

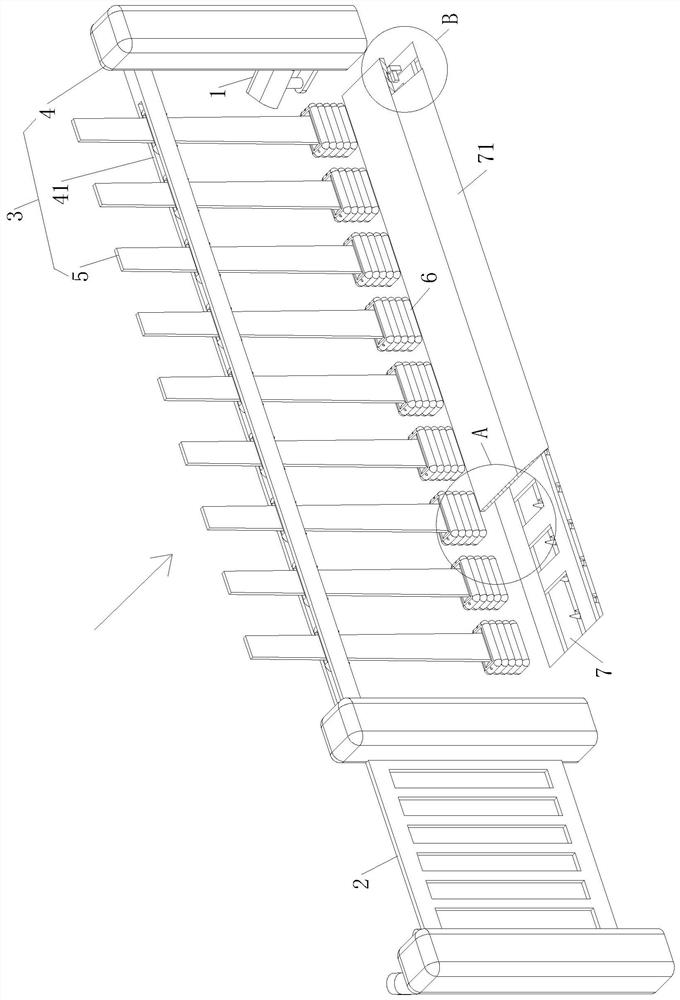

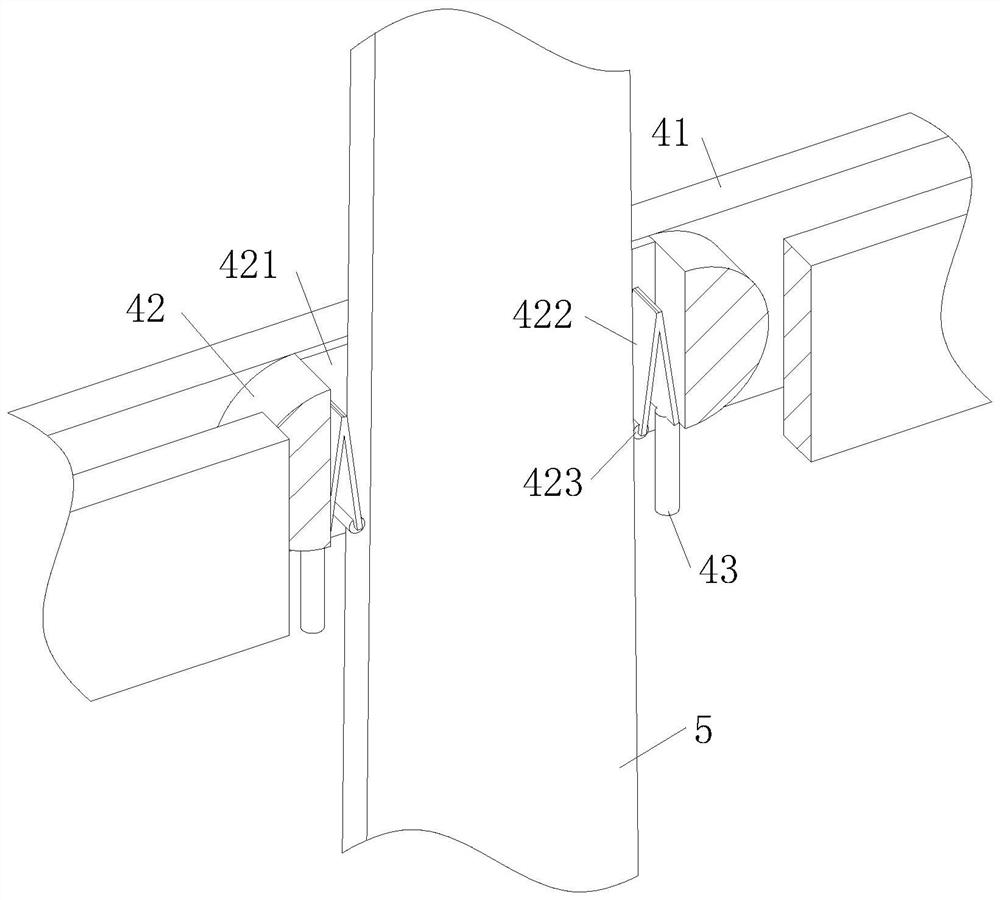

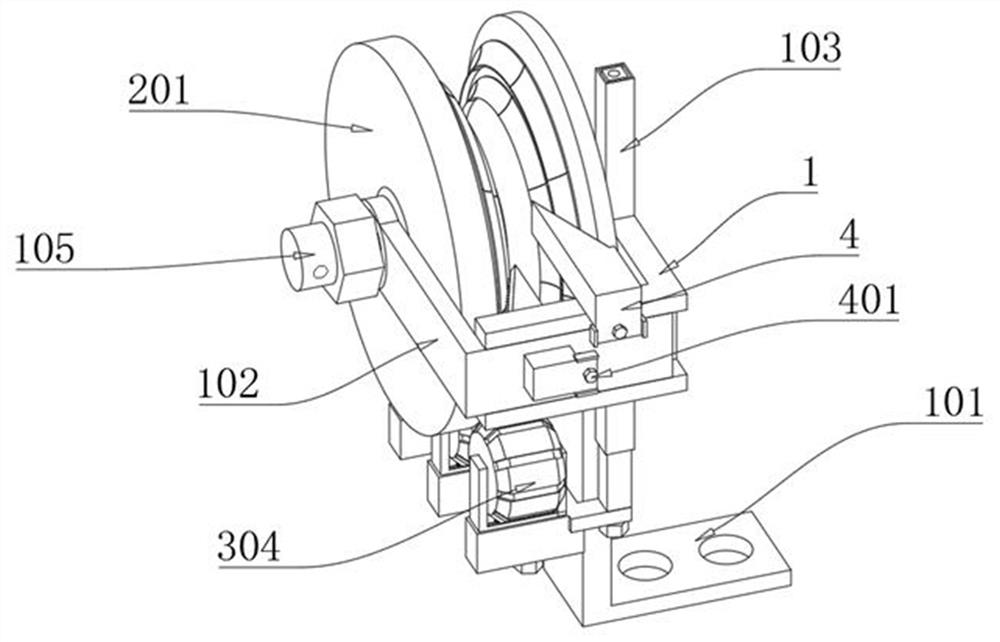

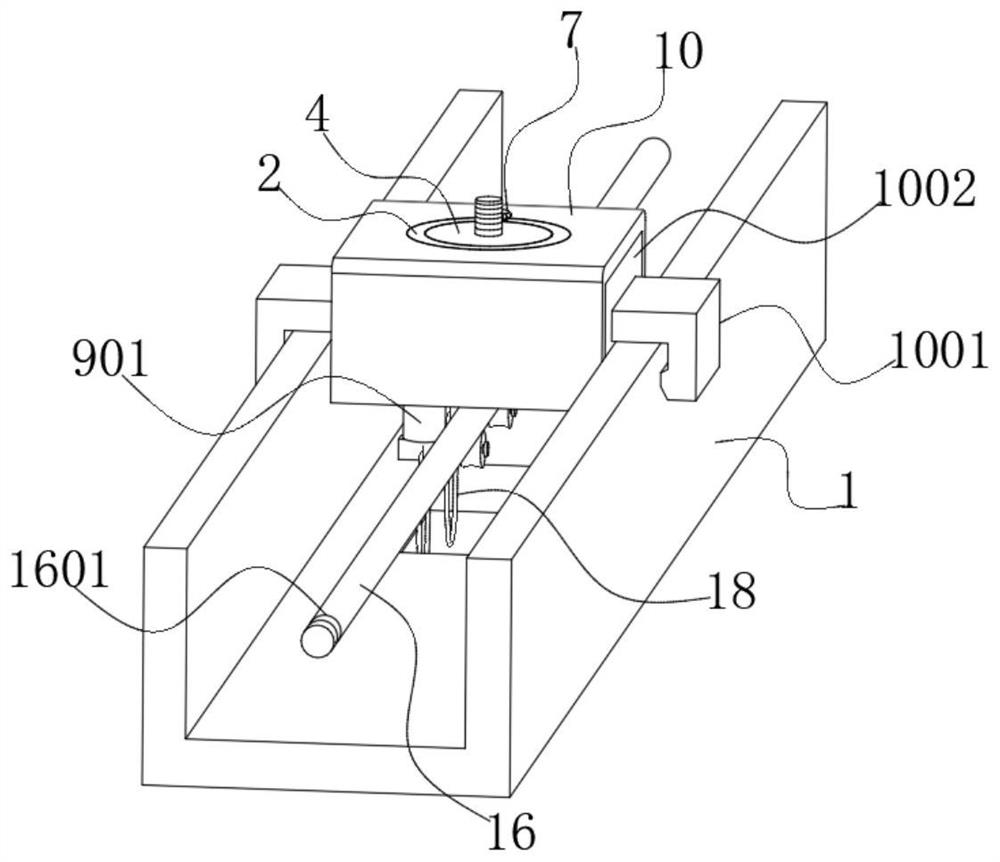

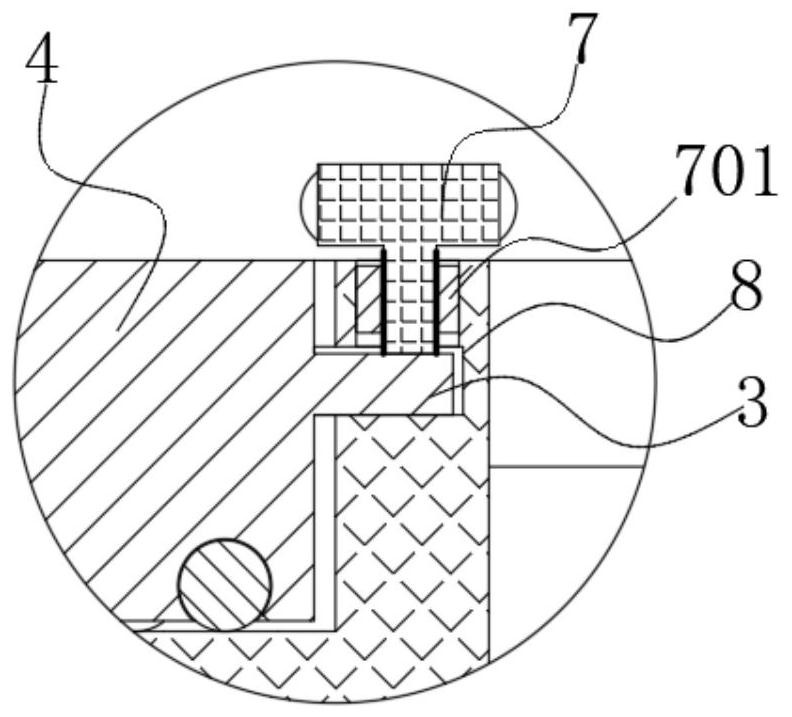

Adsorption type longitudinal glass breaking and separating device

ActiveCN108099024AImprove product qualityAvoid sliding wearWorking accessoriesStone-like material working toolsVacuum pumpingEngineering

The invention provides an adsorption type longitudinal glass breaking and separating device. The adsorption type longitudinal glass breaking and separating device includes: a support platform and a lifting mechanism for driving the supporting platform to lift; a glass breaking mechanism arranged on the center of the supporting platform; two groups of glass separating mechanisms which are symmetrically distributed on two sides of the glass breaking mechanism; two groups of adsorption mechanisms which are symmetrically distributed on two sides of the glass breaking mechanism, wherein each adsorption mechanism includes an adsorption bracket, a vacuum-pumping system and a vacuum breaker valve, the adsorption bracket is fixedly connected to a movable platform, a top surface of the adsorption bracket is an adsorption surface contacting glass and has a plurality of adsorption holes, the adsorption holes are connected to the vacuum-pumping system through an adsorption channel, and the vacuum breaker valve is arranged on the adsorption channel. During a whole glass breaking and separating process, the glass does not contact glass conveying rollers, sliding abrasion between a bottom surfaceof the glass and the glass conveying rollers can be avoided, and the production quality of the glass is improved.

Owner:CHINA TRIUMPH INT ENG

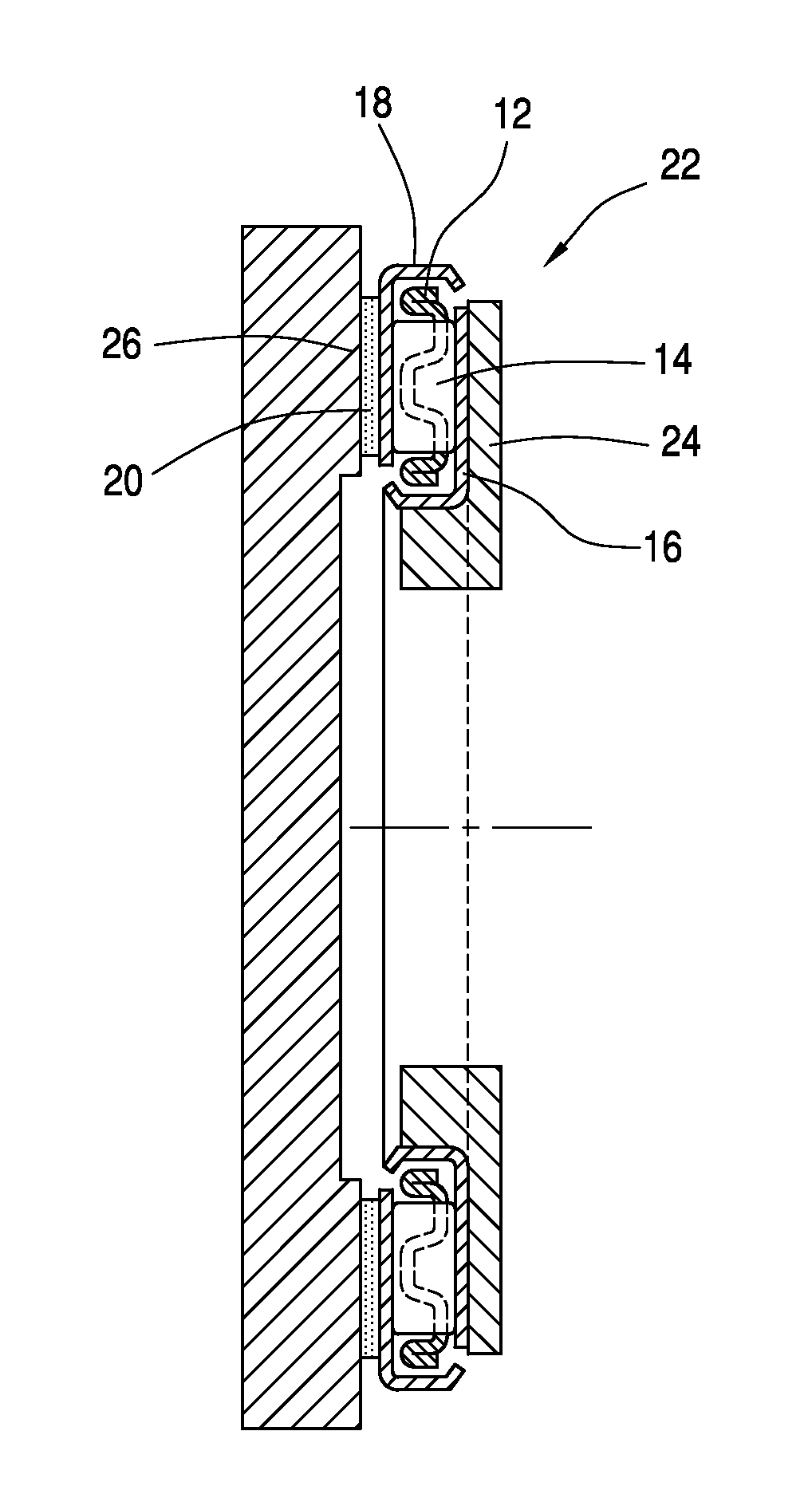

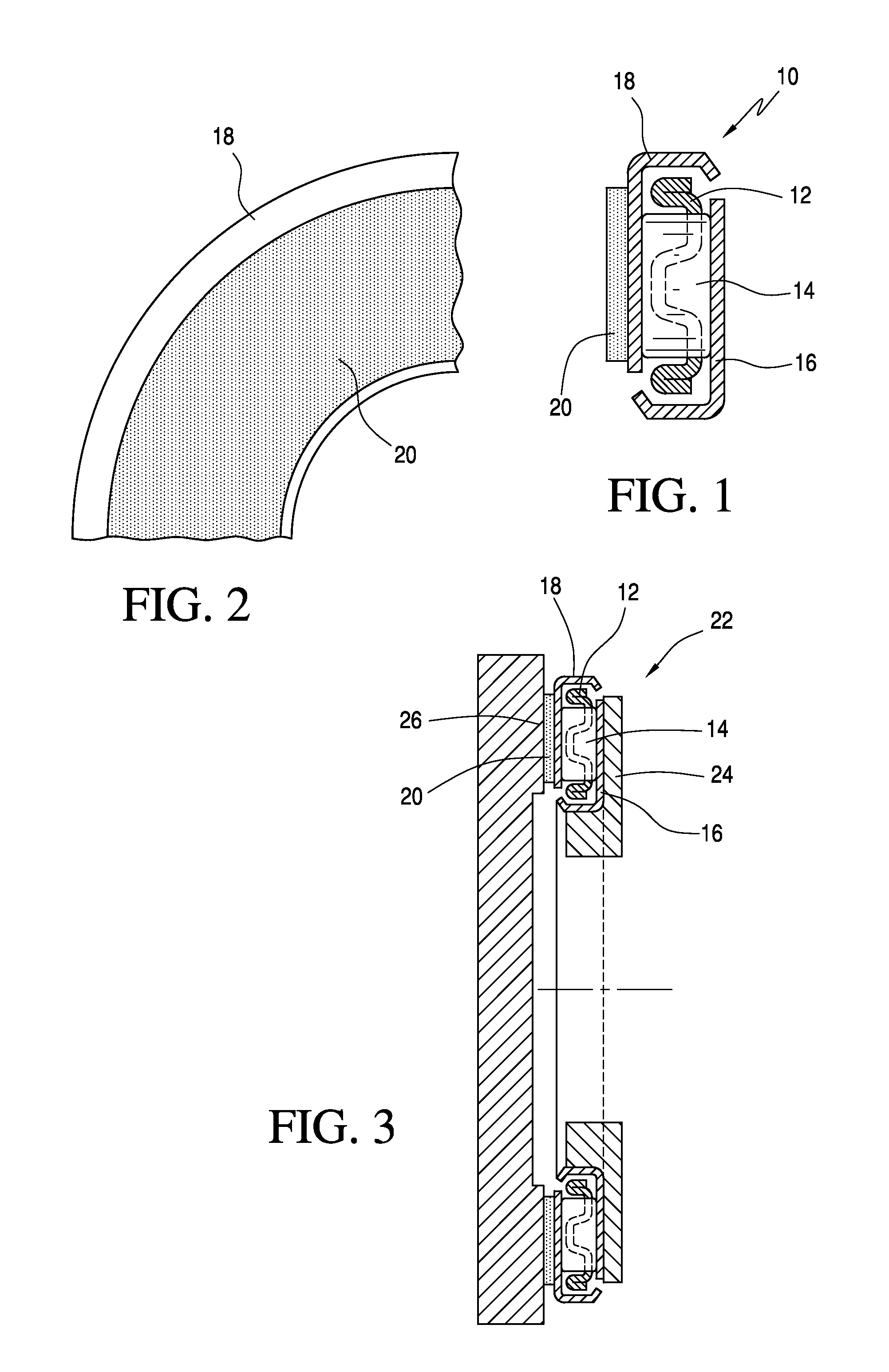

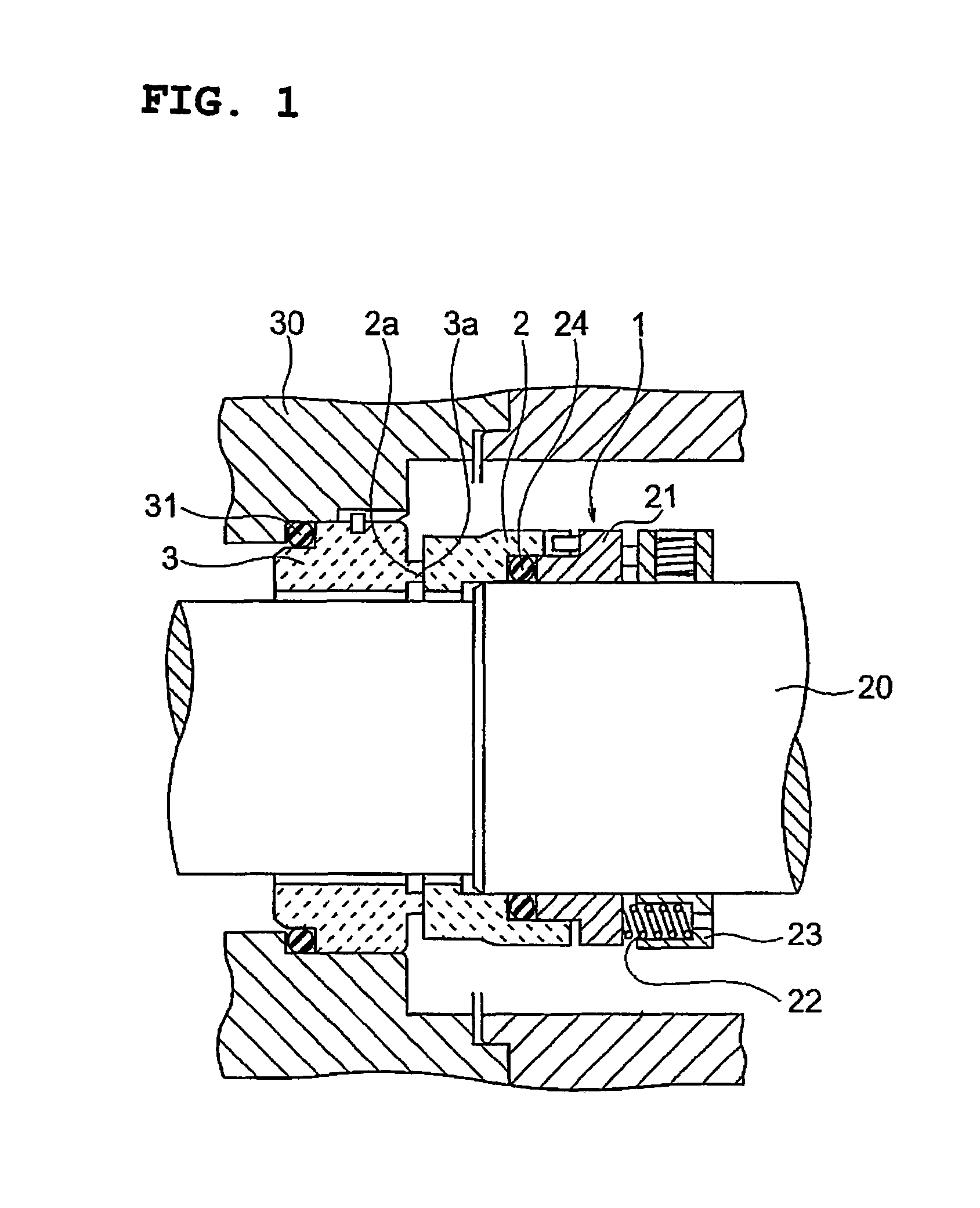

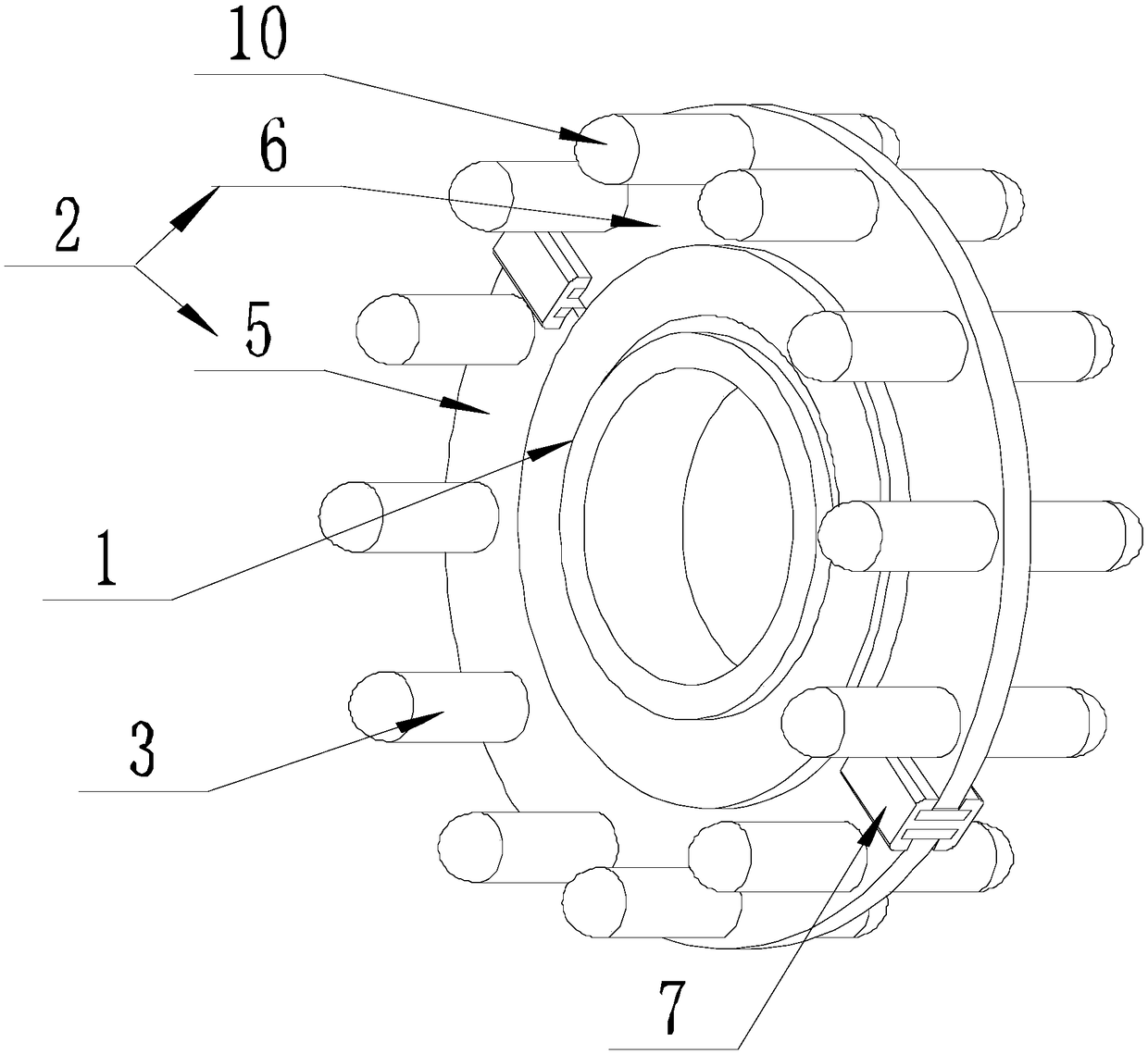

Thrust needle roller bearing with isolating layer

InactiveUS20110182542A1Prevent creepAvoid sliding wearBearing componentsNeedle bearingsNeedle roller bearingAdhesive

A thrust needle bearing with an isolating layer has a cage with rollers, washers on which the rollers run, at least one of the washers is attached to the cage, backup surfaces fixed external to each of the washers and an isolating layer attached to at least one of the washers, which is interposed between the at least one of the washers and at least one of the backup surfaces of the bearing. The isolating layer is a layer of vibration-attenuating material. Alternatively, the isolating layer is a layer of material which has properties that prevent creep or sliding wear for at least one of the backup surfaces. The isolating layer is attached to the washers by bonding, use of adhesives or mechanical means.

Owner:SCHAEFFLER TECH AG & CO KG

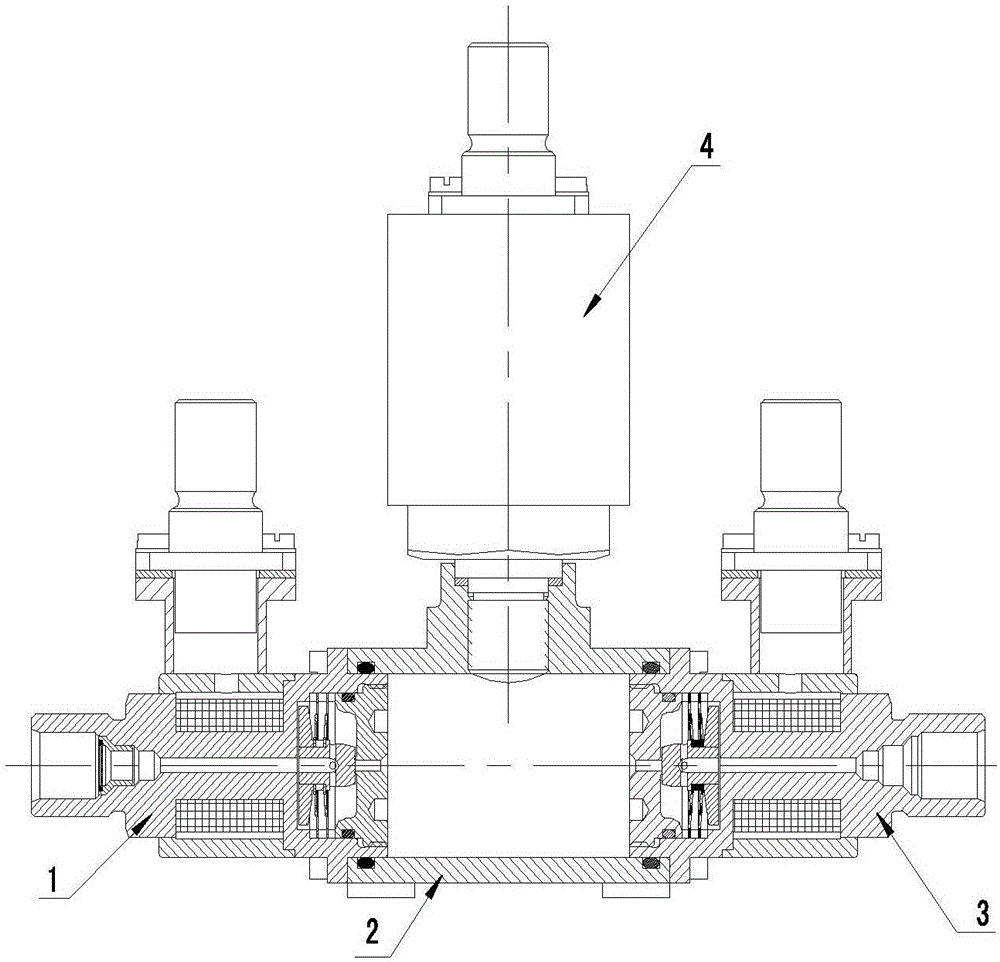

Flow control electromagnetic valve

ActiveCN106523723AExtended service lifeAvoid sliding wearOperating means/releasing devices for valvesLift valveEngineeringControl valves

The invention aims to achieve the technical effect of providing a flow control electromagnetic valve which can overcome the defects that in the prior art, structures are complex, the reliability is poor, and valves are not suitable for macroscopical adjustable working conditions. The flow control electromagnetic valve comprises a cavity substrate, a first electromagnetic valve body and a second electromagnetic valve body. The first electromagnetic valve body and the second electromagnetic valve body are arranged on the two sides of the cavity substrate correspondingly. A medium enters the cavity substrate through the first electromagnetic valve body and then flows out of the second electromagnetic valve body. Due to the fact that the friction-free electromagnetic valve combination is adopted for flow control, sliding abrasion between a valve element and a guiding face of a traditional direct operated type electromagnetic valve is completely avoided, the service life of the electromagnetic valve is greatly prolonged, and compared with traditional flow control valves, the electromagnetic valve is simple in structure, easy to control, stable in flow, reliable in operation, long in service life and good in economical efficiency.

Owner:XIAN AEROSPACE PROPULSION INST

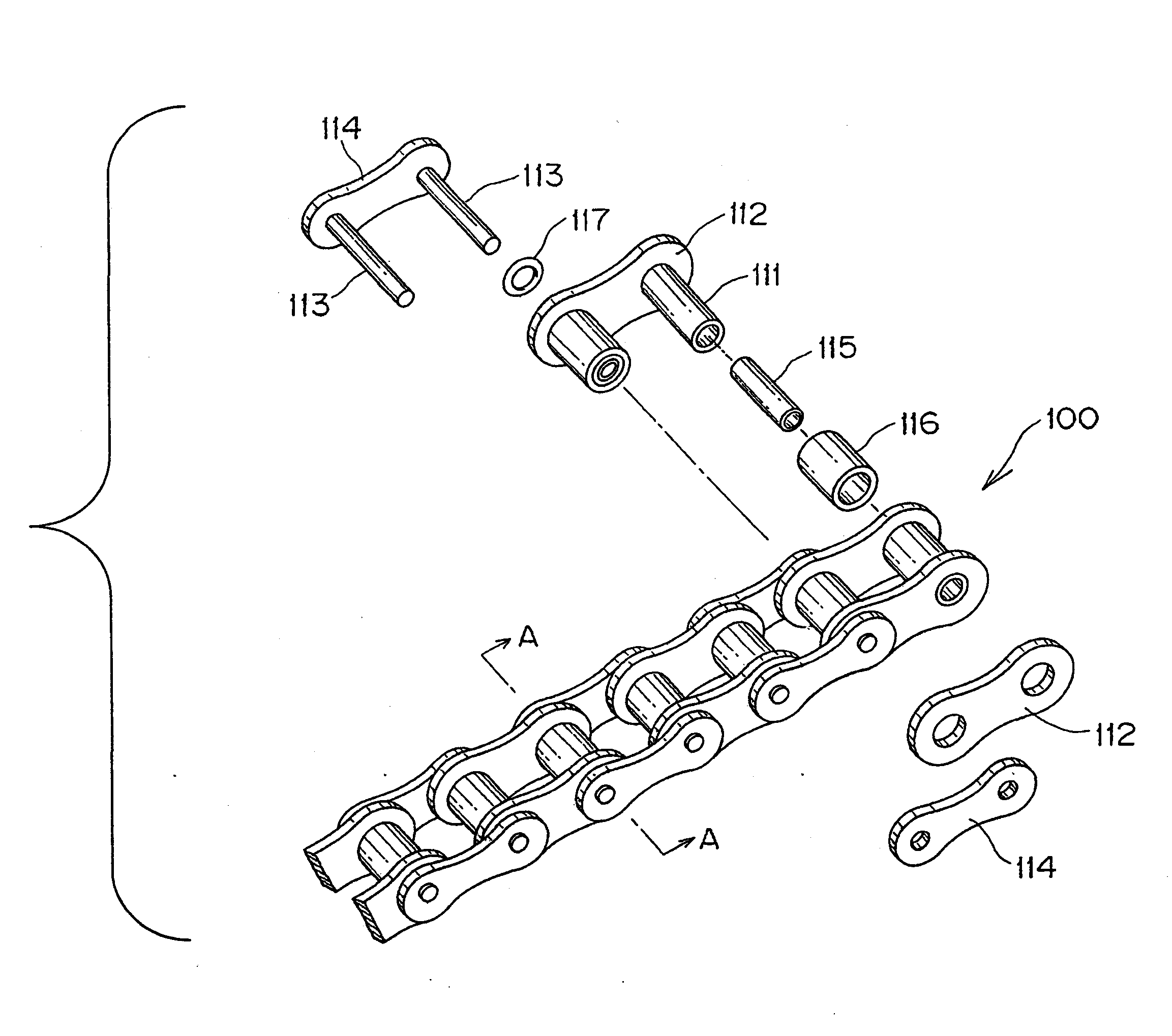

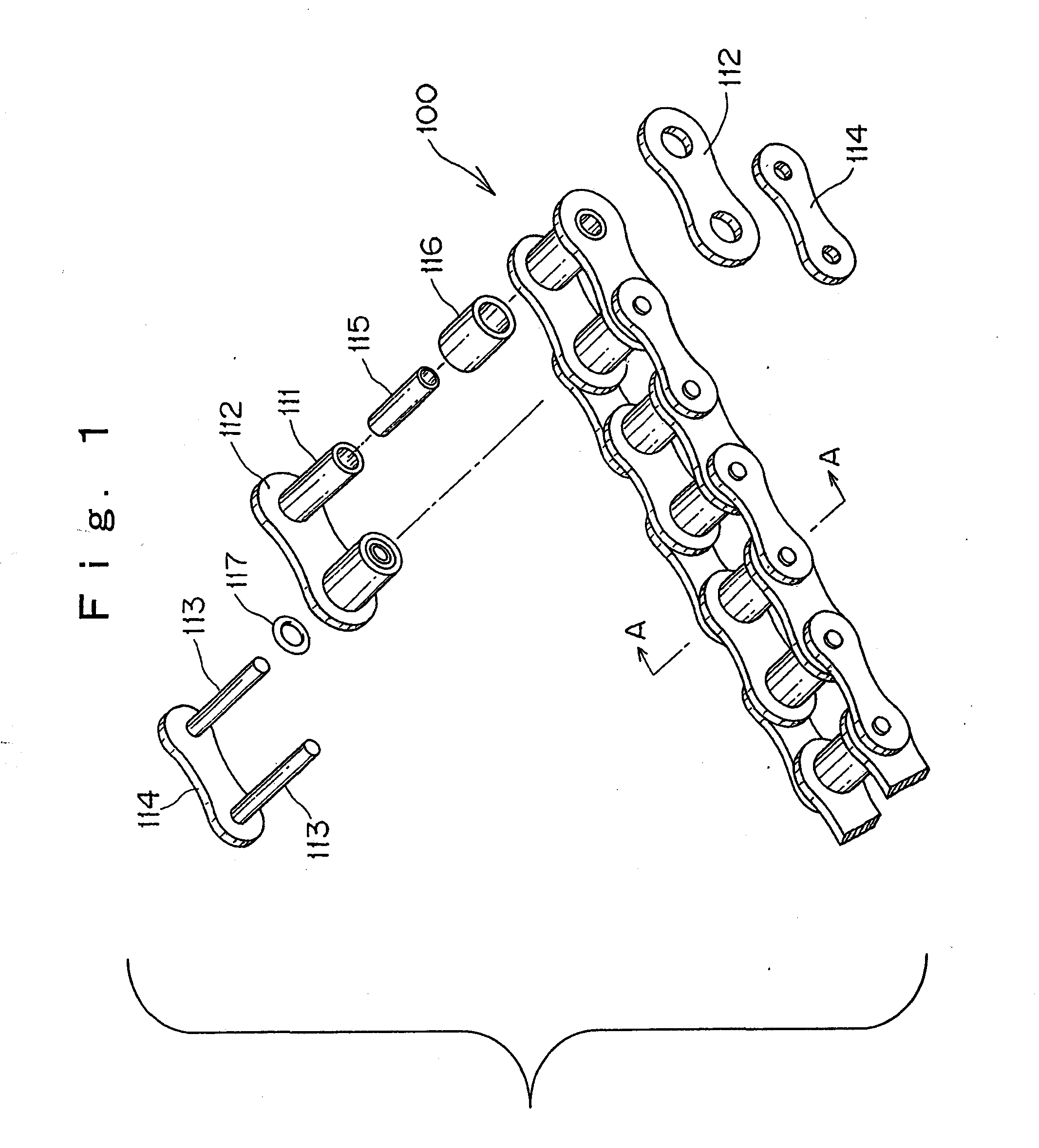

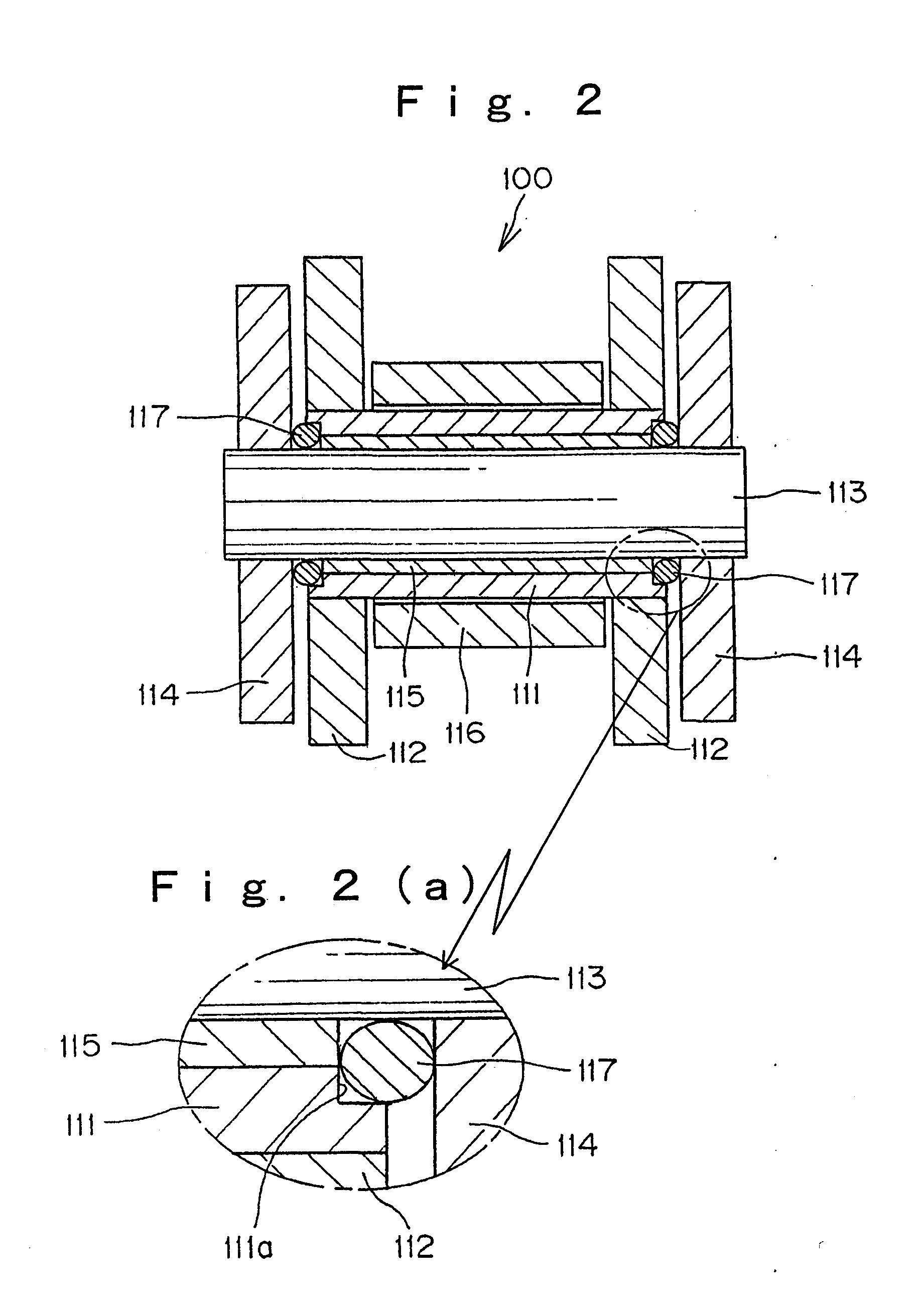

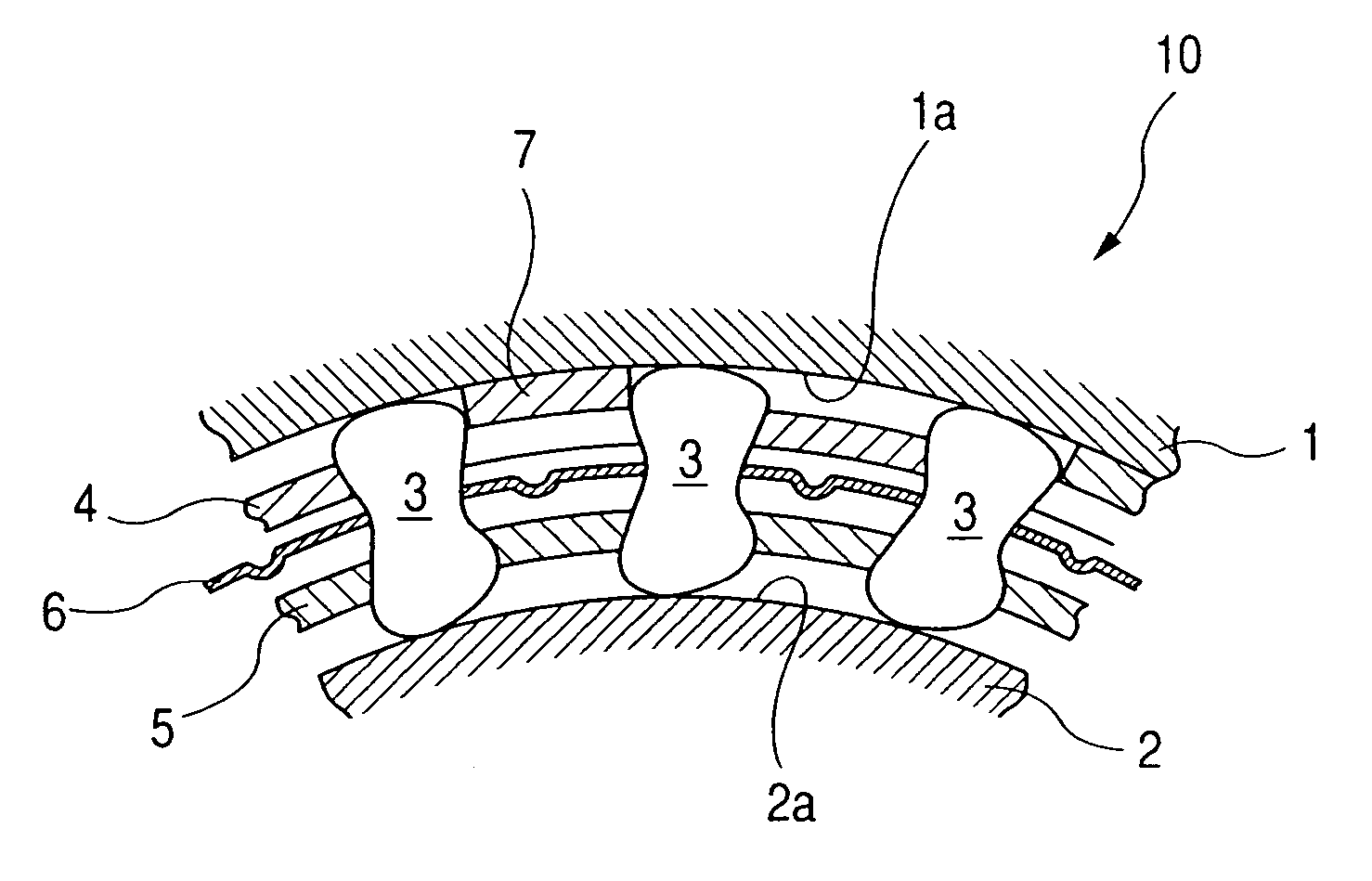

Solid lubrication oil-free chain

InactiveUS20100285912A1Avoid sliding wearImprove the lubrication effectDriving chainsOil freeRoller chain

An oil-free chain that includes excellent lubricating properties, and satisfactorily maintains the lubricating properties even in high temperature atmosphere and dust particle atmosphere so that a stable lubrication effect can be maintained for a long period of time. The chain is a bush chain having a pair of inner plates into which the opposite ends of a bush are fitted, and a pair of outer plates which mount the opposite ends of a pair of pins. The pins are rotatably fit-inserted into the bushes of adjoining outer link plates. The inner and outer plates are connected in alternation to form the roller chain in which a roller is rotatably mounted on the outer surface of each bush. A sliding member formed of a 100% graphite sheet is provided between the bush and the pin and / or between the bush and the roller.

Owner:AOKI TOSHIHIKO

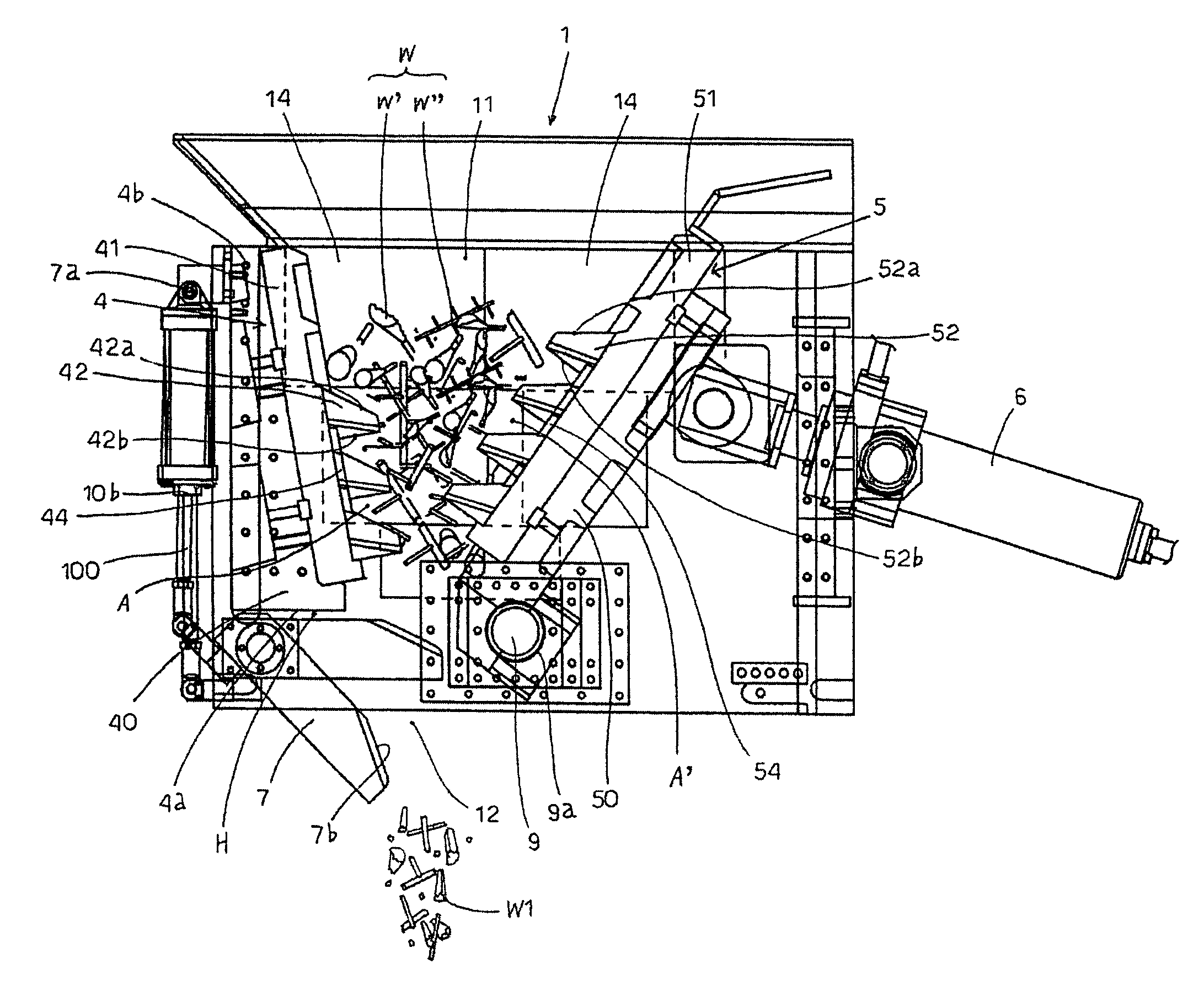

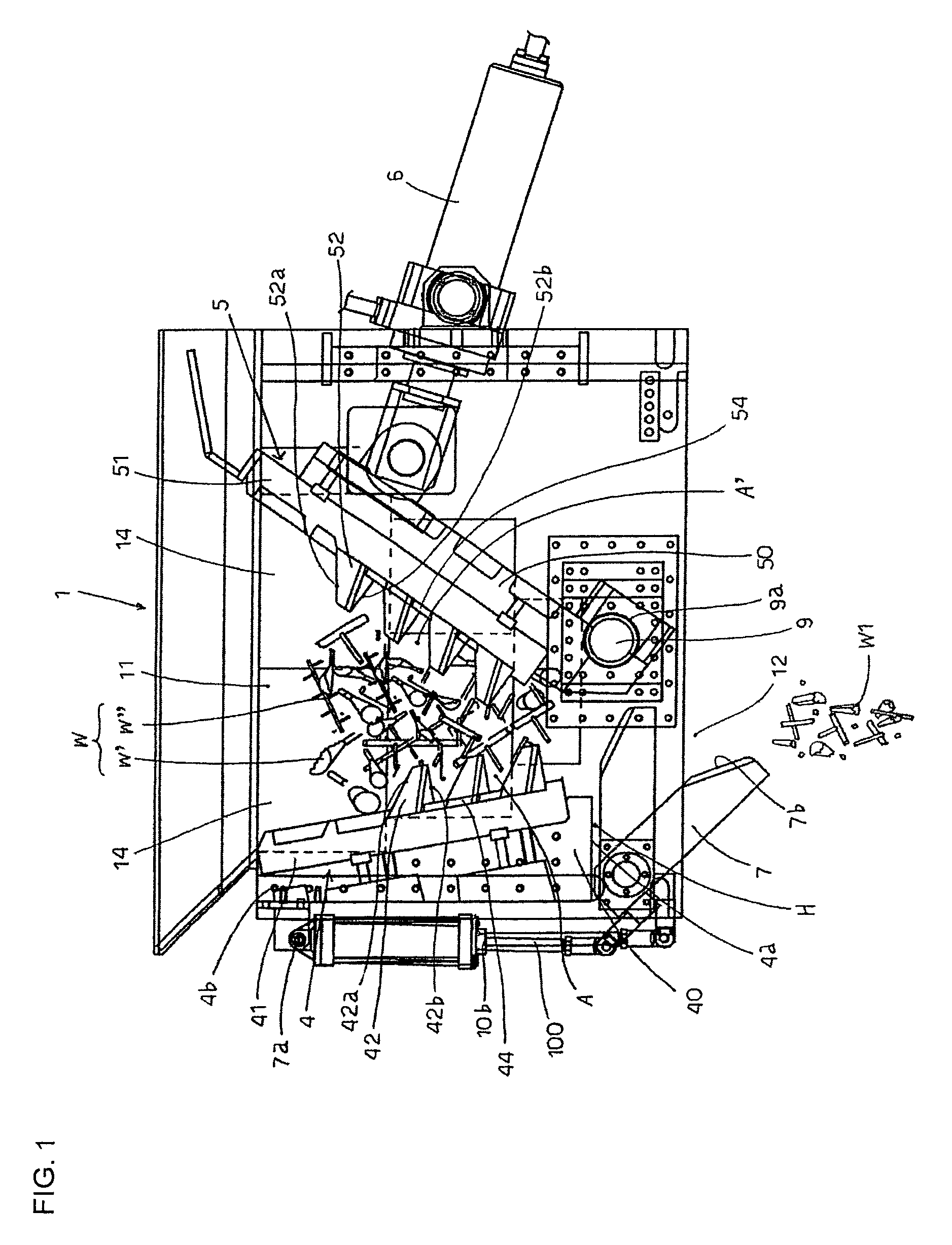

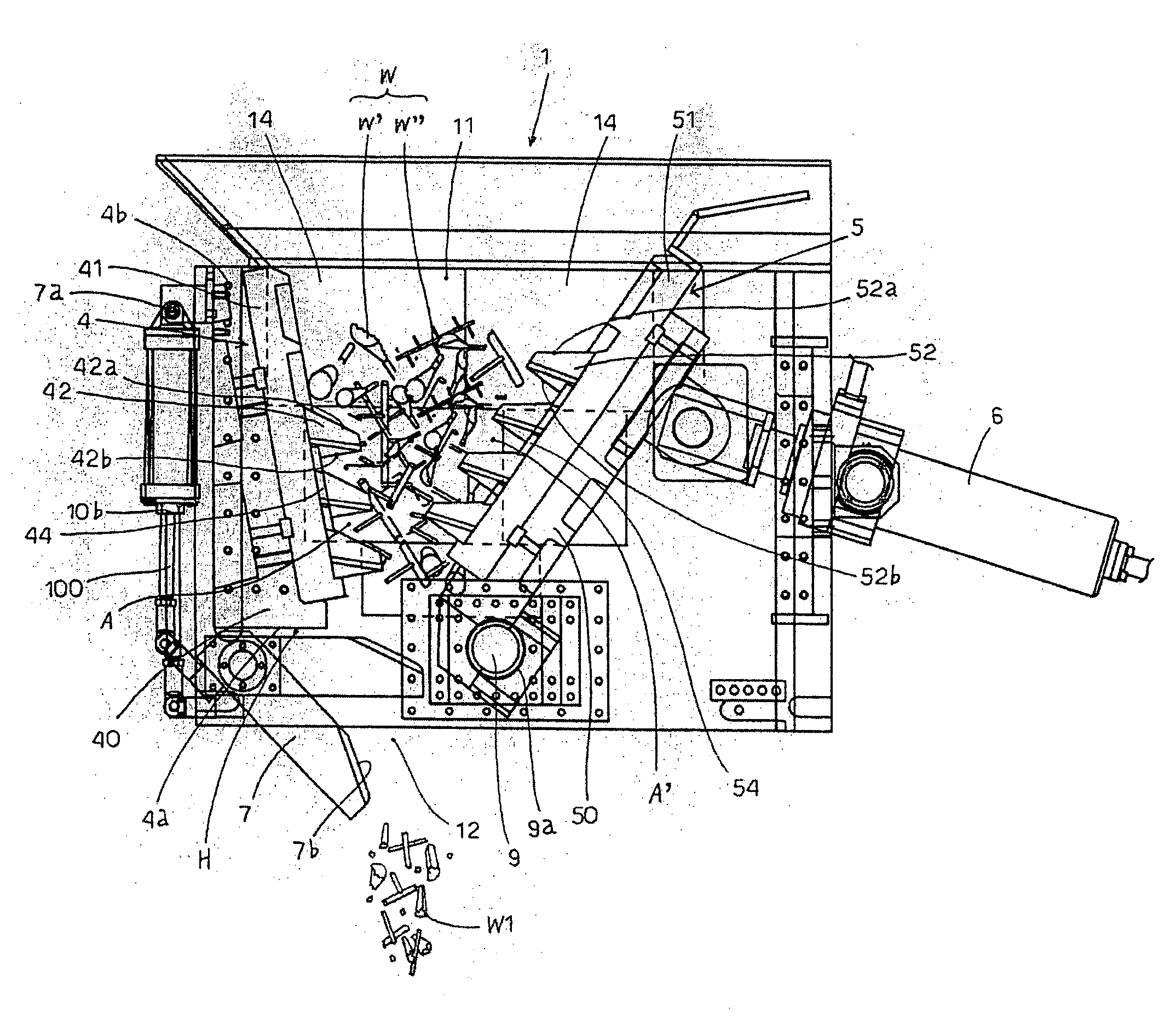

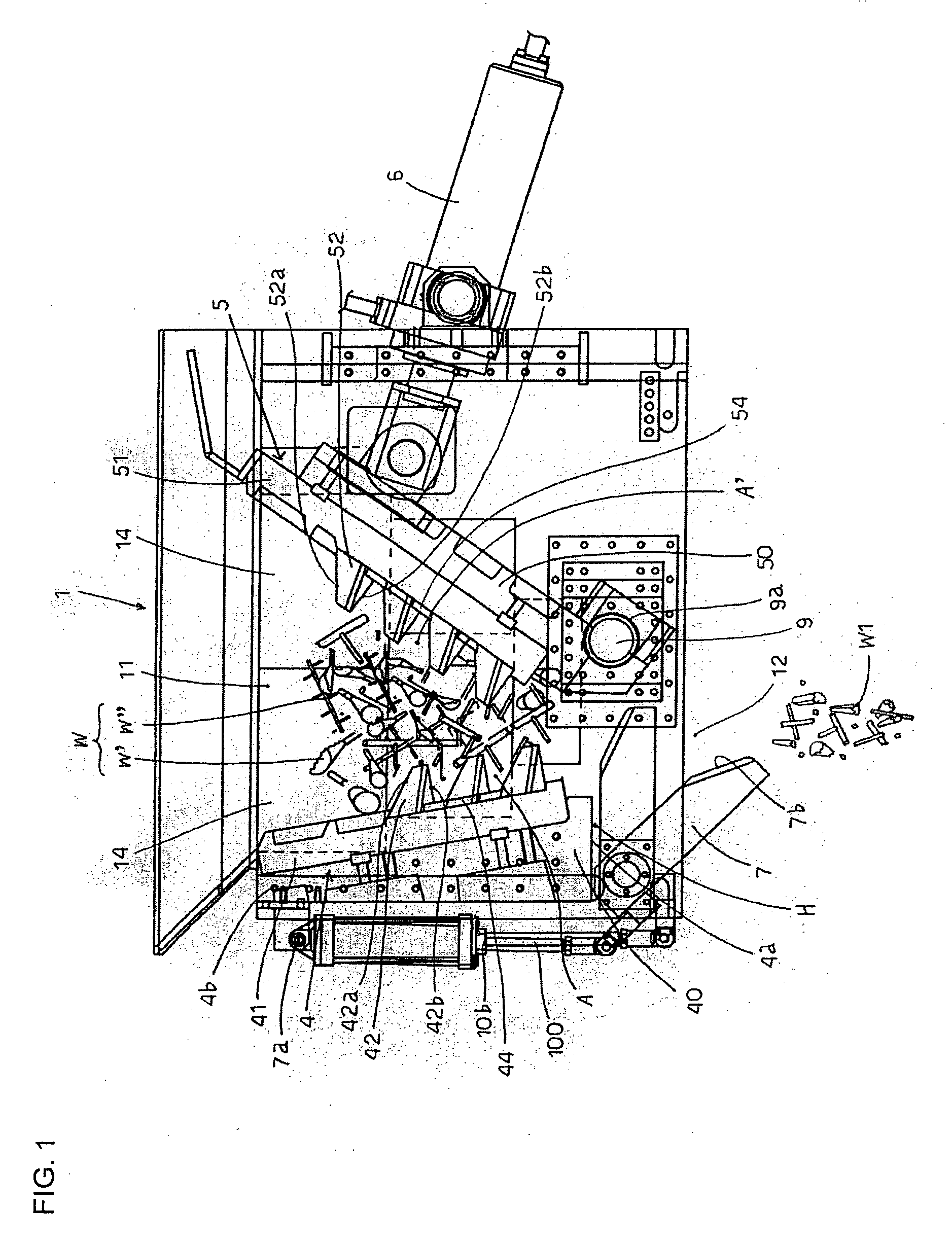

Other side tool support base and/or other side tool post mounted to casting breaking apparatus, and bearing of the other side tool support base

ActiveUS8262007B2Avoid wear and tearAvoid sliding wearBearing componentsGrain treatmentsSliding contactWaste material

A tool support base and a tool post for cutting a casting, in which contact surfaces in sliding contact with both side plates are formed on both sides of the tool support base and the tool post. A cut recess is formed in the sliding contact surface so as to vertically extend in the surface. Deposit welding is applied to the cut recess and a ridge of weld deposit generally flush with the contact surface is formed by grinding means that makes the weld deposit, formed by the deposit welding, flush with the contact surface. The construction minimizes wear of the contact surface as much as possible, and even if particles of casting waste materials enter gaps between the tool support base and the tool post and the side plates, the construction can avoid wear by such particles.

Owner:OKUYA YASUAKI

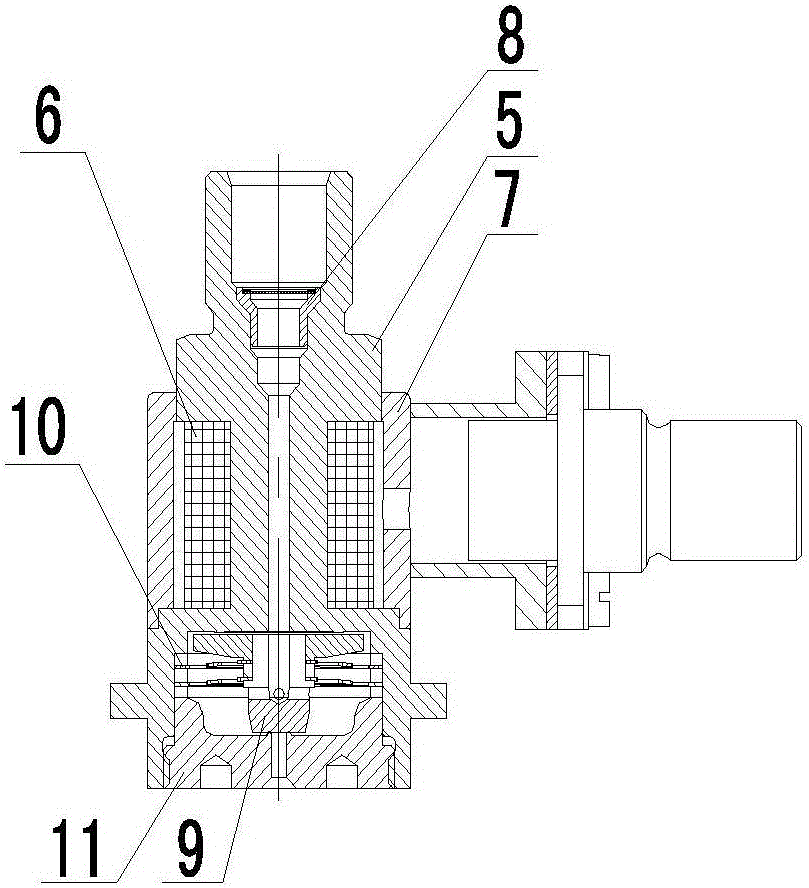

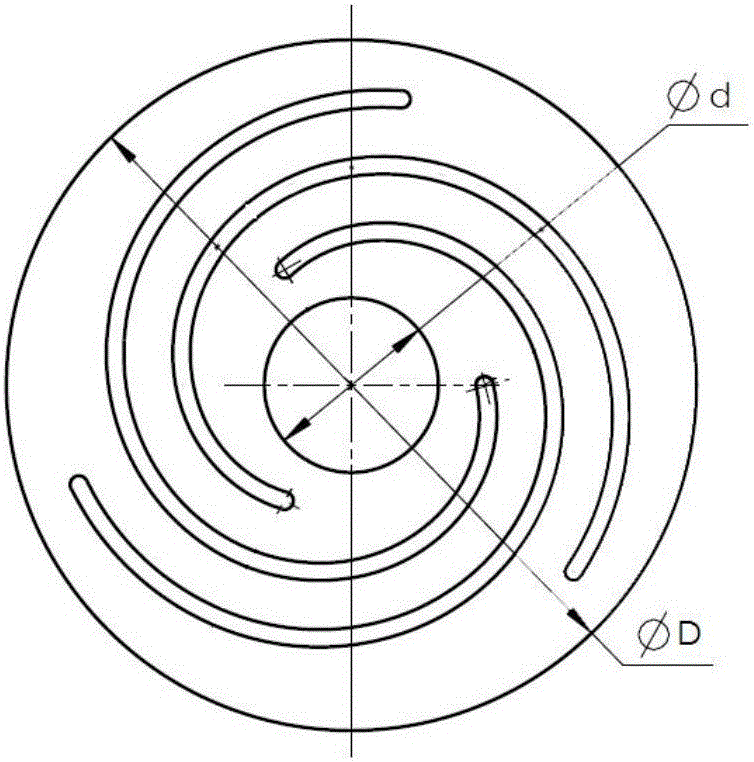

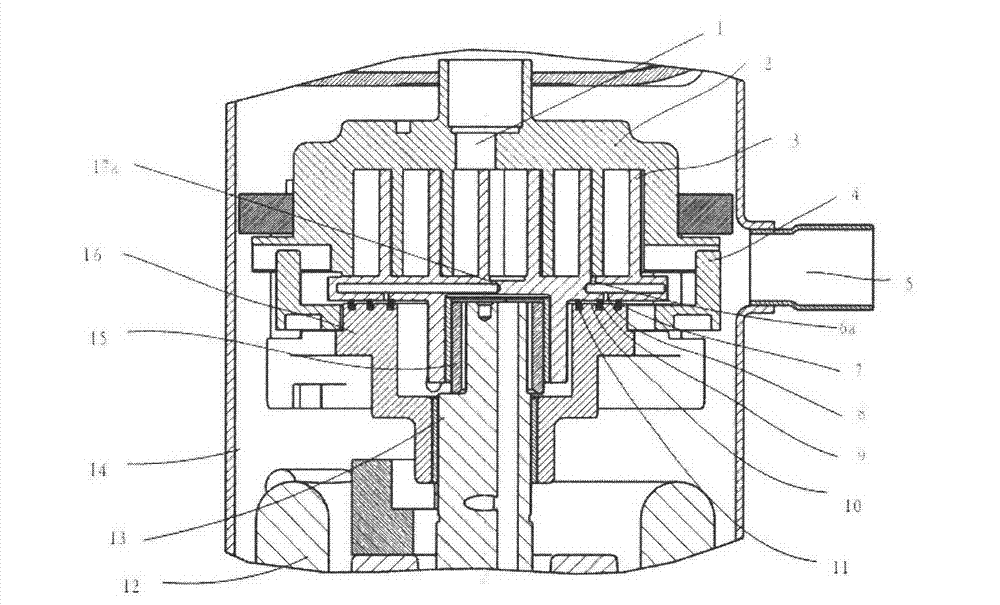

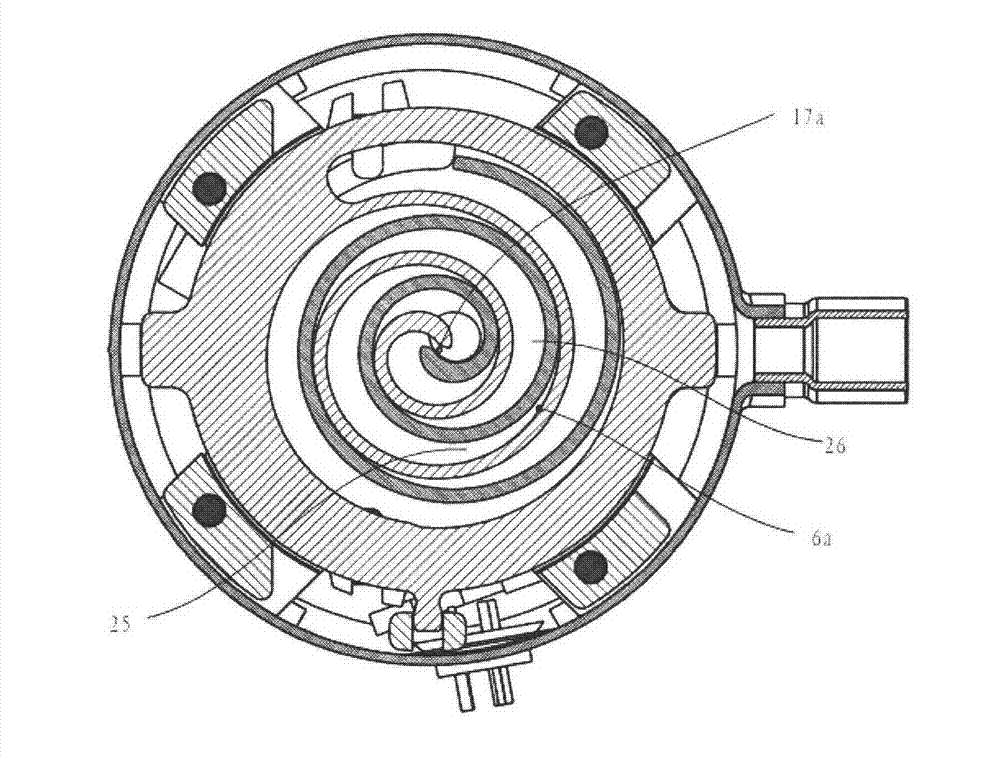

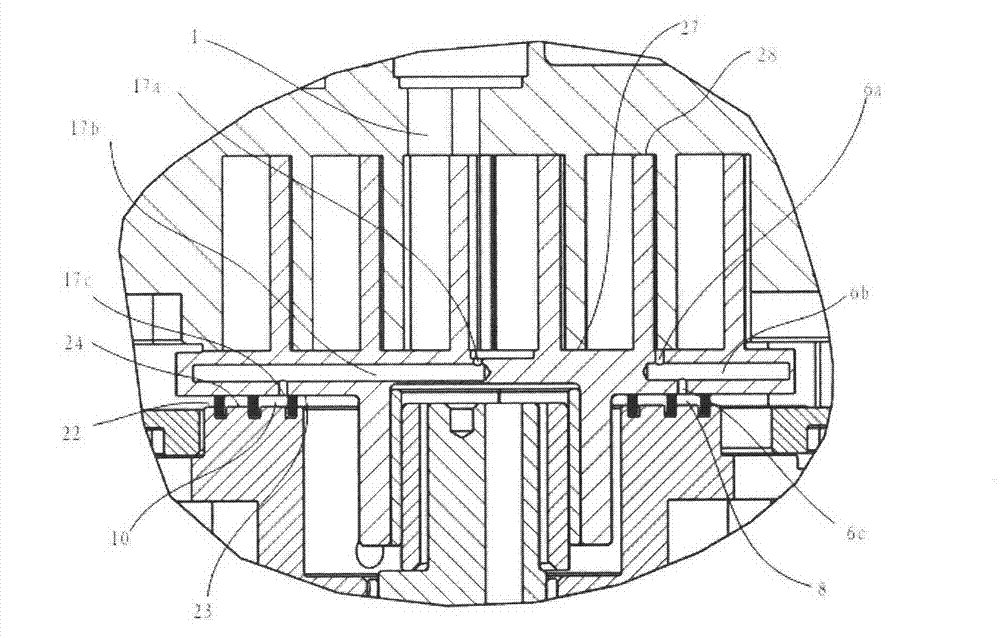

Scroll compressor with axially flexible seal

InactiveCN102889208AReduce side leakageReduced face leakageSealing arrangement for pumpsRotary piston pumpsEngineeringMechanical engineering

The invention discloses a scroll compressor with an axially flexible seal. Two backpressure cavities are arranged between a dynamic vortex plate 3 and a support frame 16, and are respectively communicated with a scroll compression cavity and an exhaust cavity, the dynamic vortex plate 3 and a static vortex plate 2 are axially close, so that an axial seal of the dynamic vortex plate 3 and the static vortex plate 2 is realized, and sliding abrasion and power consumption between the dynamic vortex plate 3 and a thrust surface 24 of the support frame 16 can be reduced.

Owner:SUZHOU INVOTECH SCROLL TECH

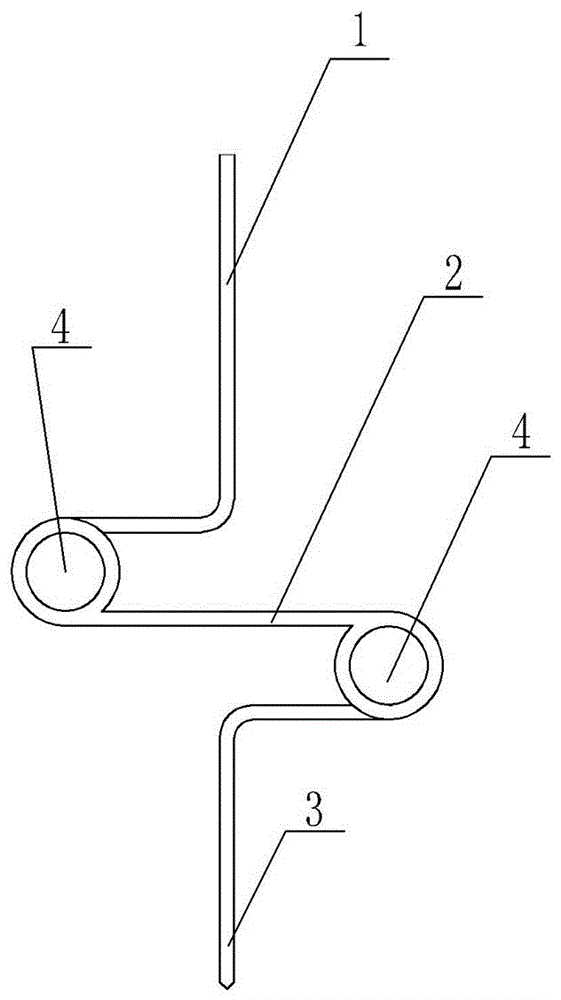

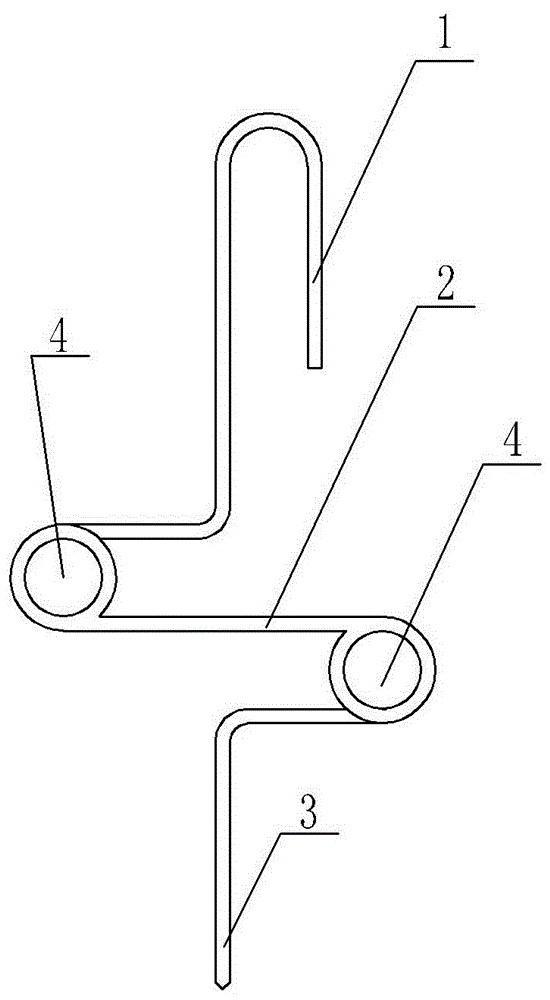

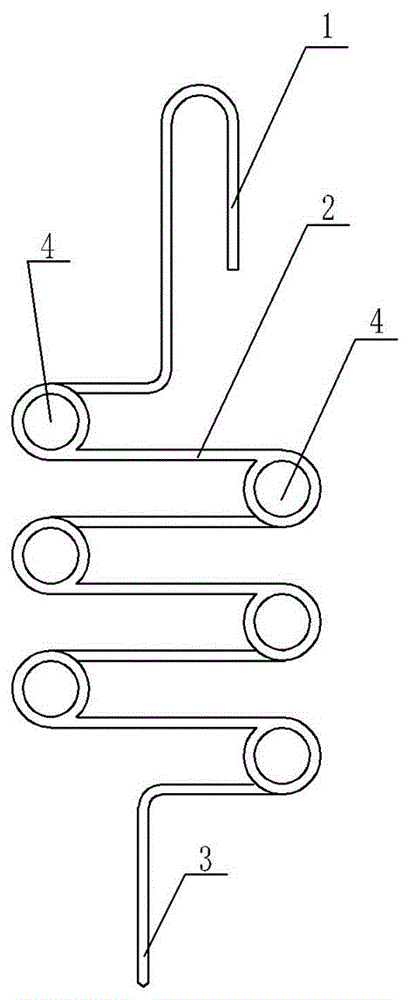

Conductor spacer rotation wire clip

InactiveCN102386598AAvoid sliding wearExtended service lifeMaintaining distance between parallel conductorsDevices for damping mechanical oscillationsTransmission lineEngineering

The invention relates to a conductor spacer rotation wire clip which is used for spacing leads on an overhead transmission line, and mainly comprises a central wire clip, a tong-shaped arm and a plurality of rollers, wherein the central wire clip is provided with a wire pressing groove for fixing leads; one end of the tong-shaped arm is provided with a tong-shaped buckle; the central wire clip is fixed in the tong-shaped buckle through the plurality of rollers installed at the inner side, and can rotate in the tong-shaped buckle of the tong-shaped arm by taking the leads as the axis; and the other end of the tong-shaped arm has a handle-shaped structure, and can be connected with a spacer bracket. By adopting the conductor spacer rotation wire clip for an overhead transmission line, the leads clamped have rotation freedom and can twist freely along with the central wire clip under the eccentric force of eccentric ice coating, so that the eccentric ice coating can not be formed finally, and the aim of preventing the transmission line from waving can be achieved. Compared with the prior art, the central wire clip of the conductor spacer rotation wire clip and the tong-shaped arm are connected by adopting the rollers, and has the advantages of wear resistance, flexible rotation, hard freezing and the like.

Owner:GULIFA GRP CO LTD +1

One-way clutch

InactiveUS20070029153A1Adequate engaging abilityReduce rotationFriction clutchesCouplingsControl theoryClutch

The present invention provides a one-way clutch comprising an outer race, an inner race rotatable relative to the outer race and torque transmitting members for transmitting torque between the outer race and the inner race and wherein a plurality of grooves extending substantially in a circumferential direction are formed in an outer peripheral track surface of the inner race.

Owner:NSK WARNER

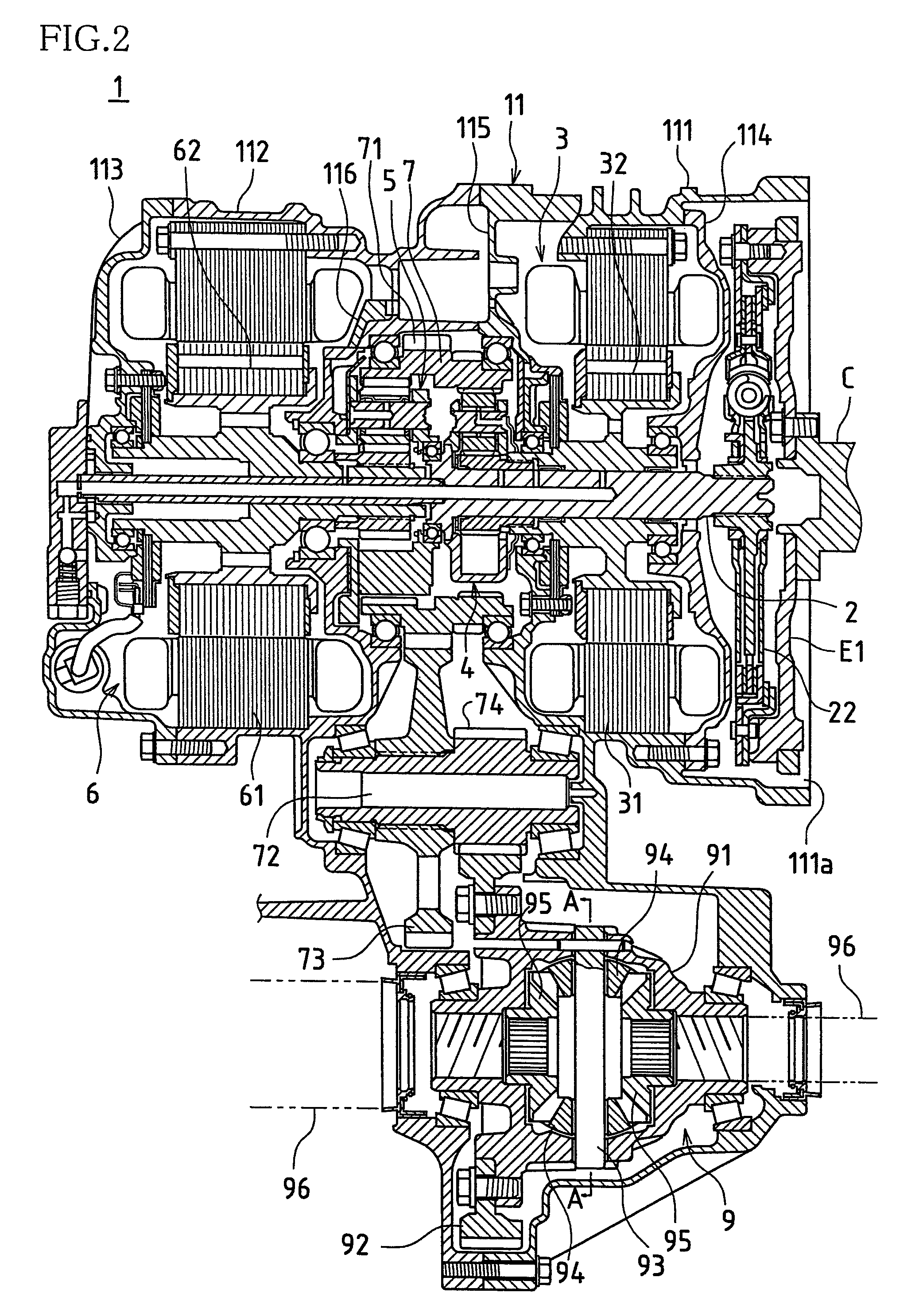

Differential device

InactiveUS7789786B2Simple configurationSure and reliable mannerElectric propulsion mountingGear lubrication/coolingGear wheelPinion

Owner:TOYOTA JIDOSHA KK

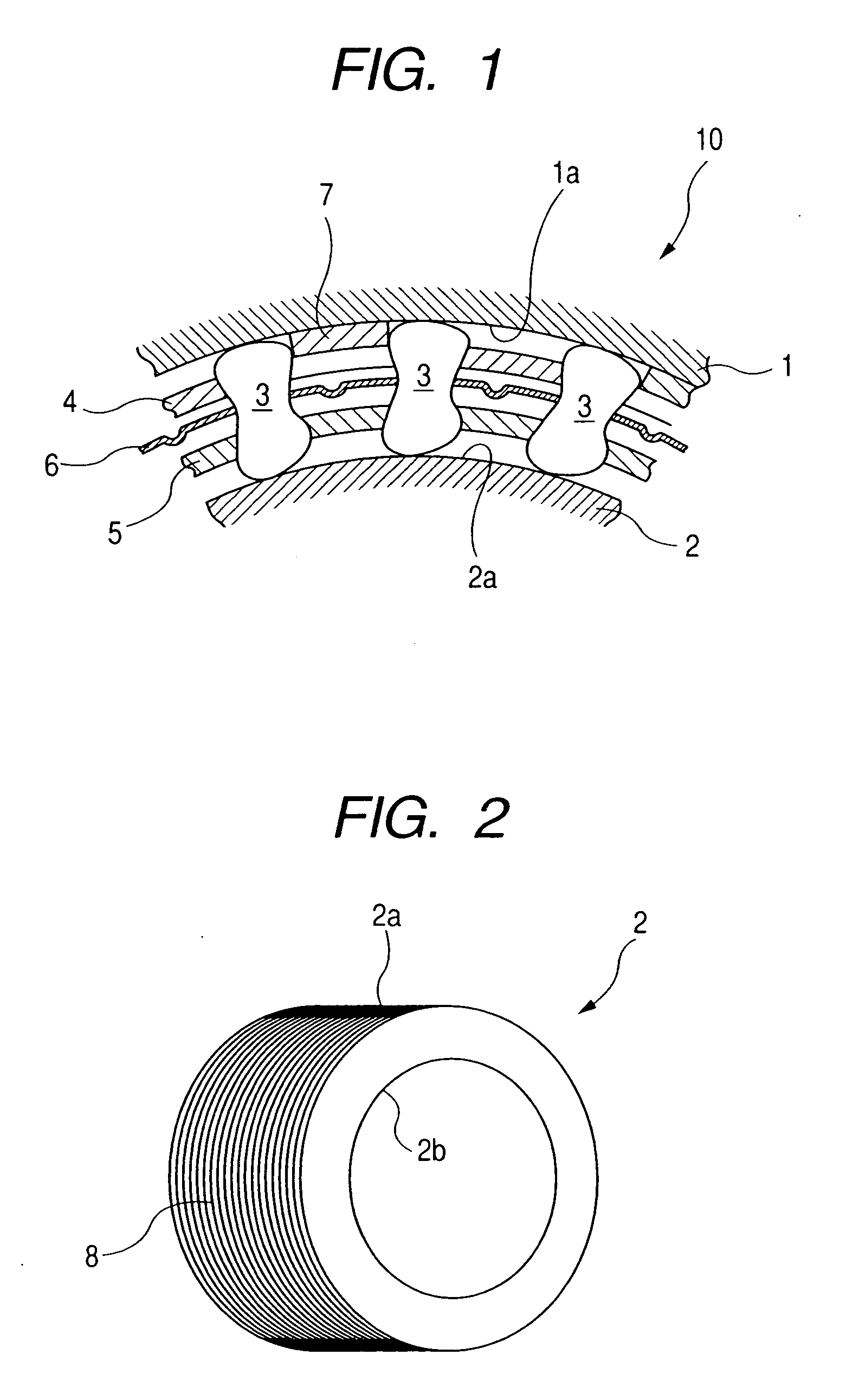

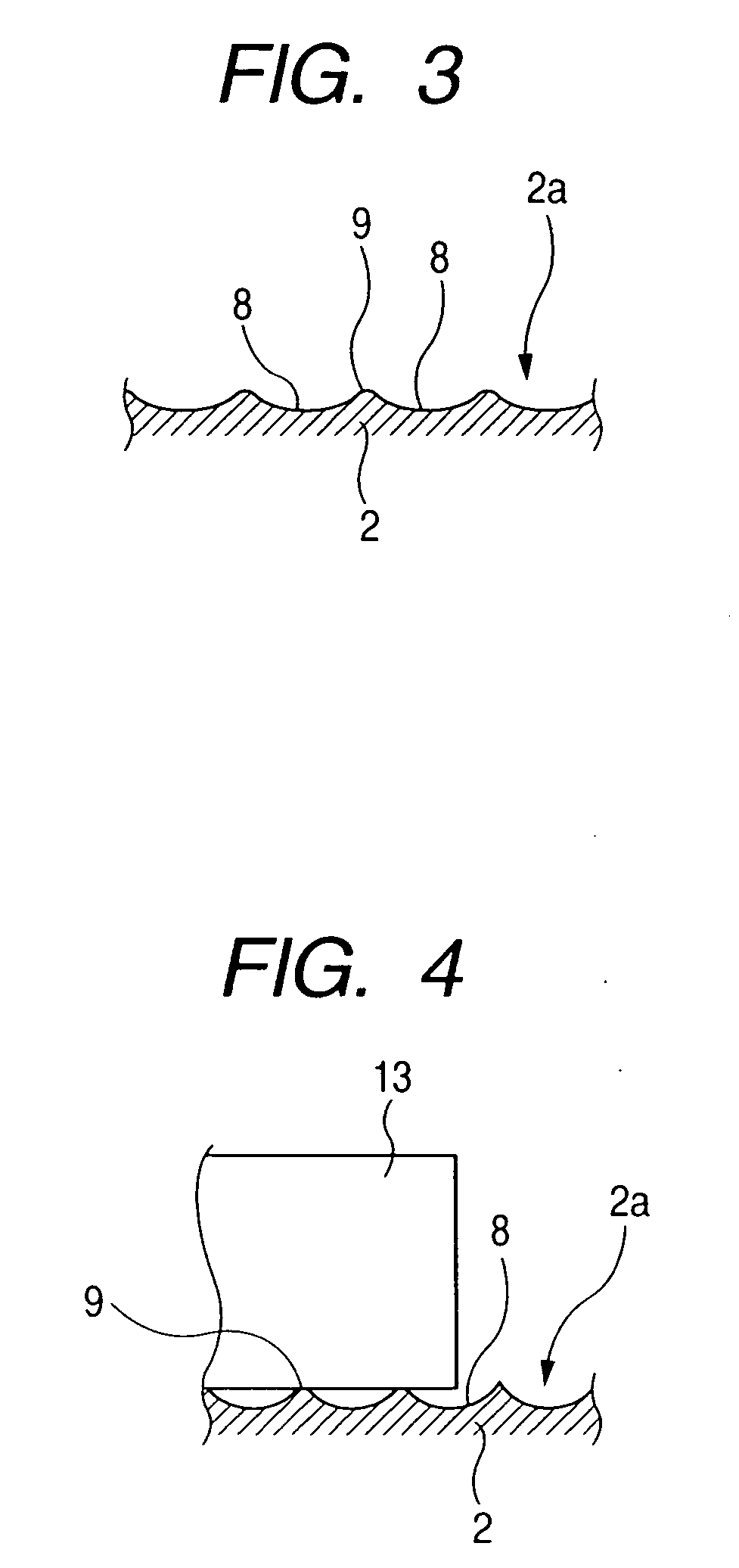

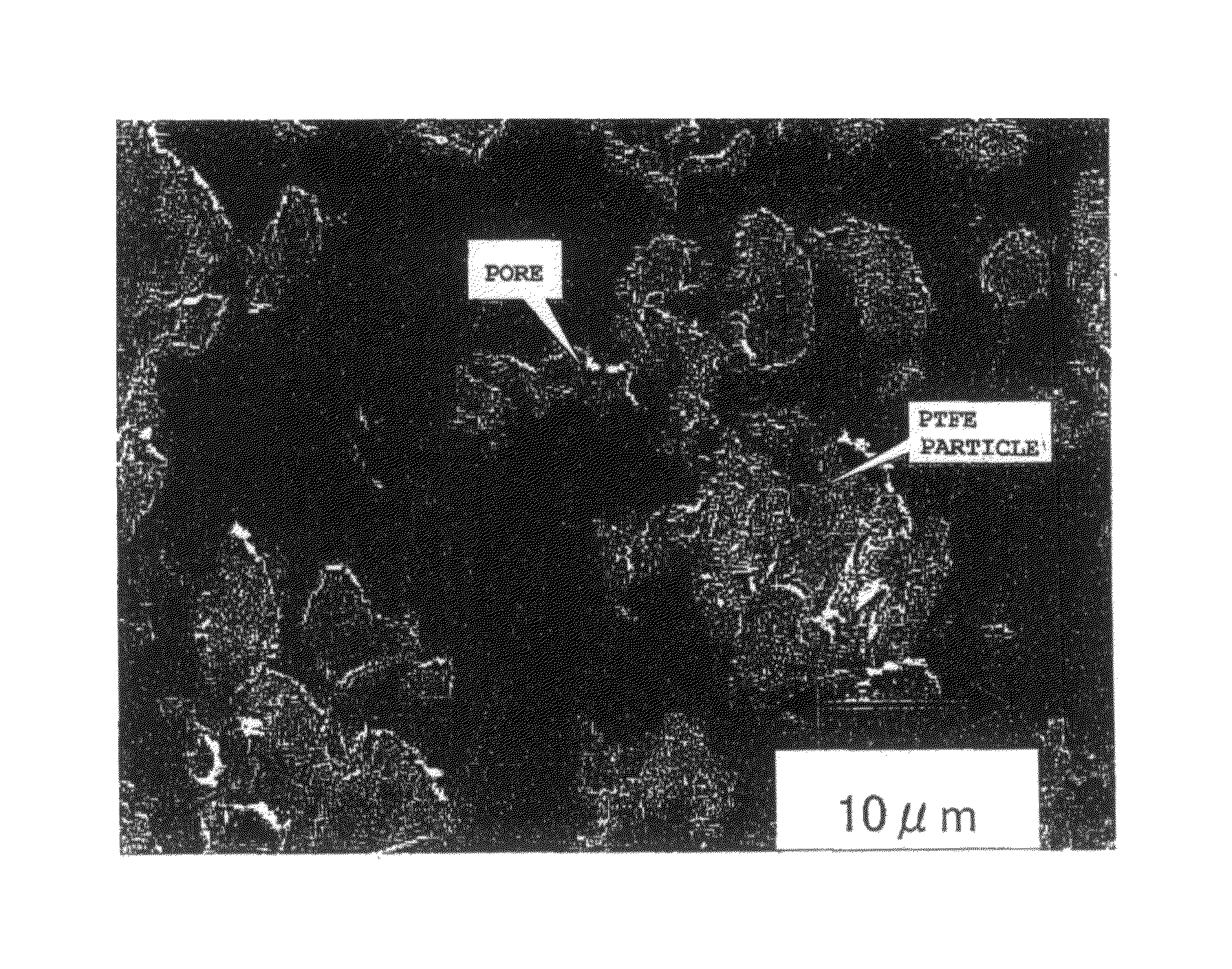

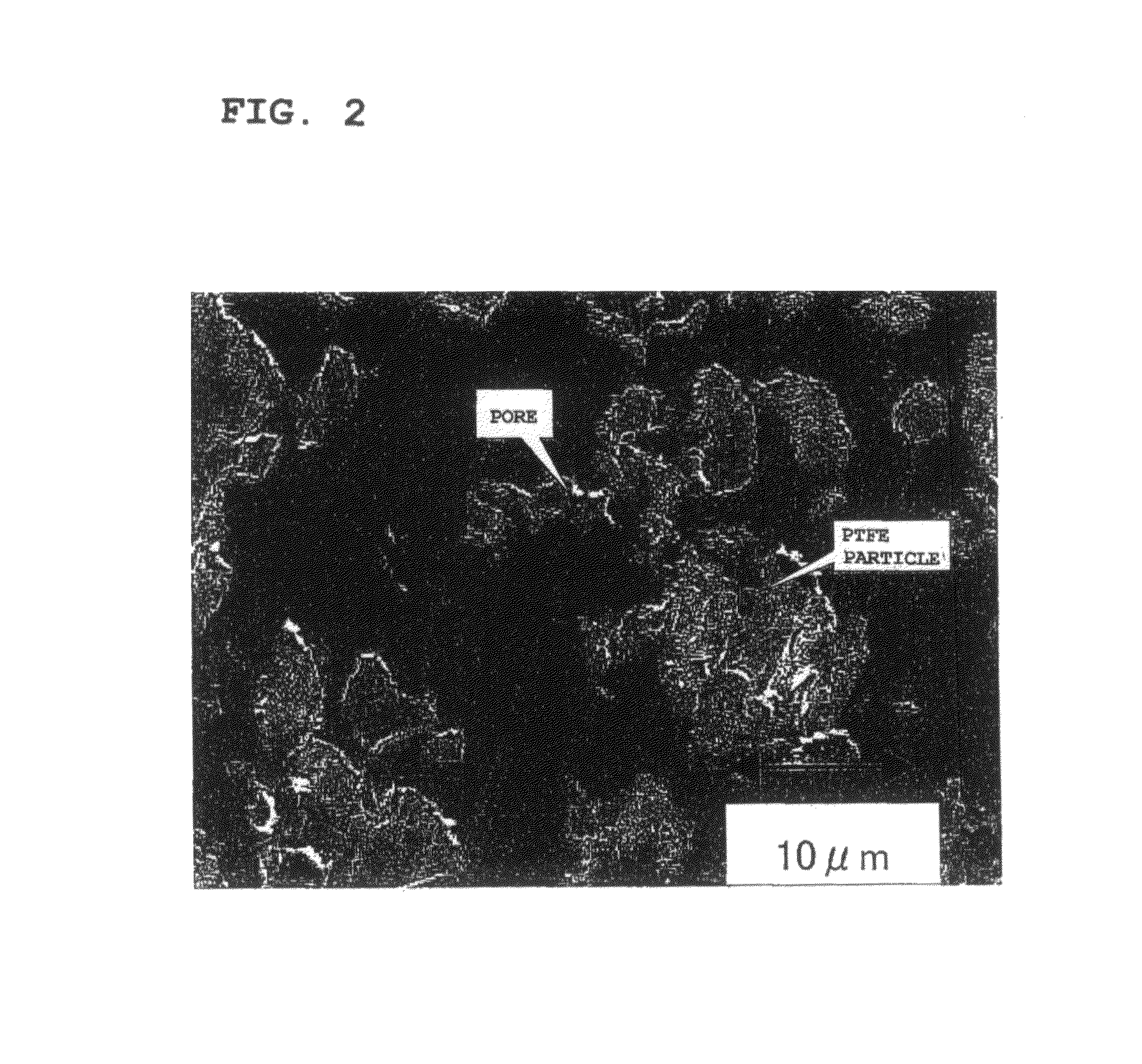

Mechanical seal device, sliding element, and method of production thereof

ActiveUS8440295B2Avoid sliding wearReduce generationSemi-permeable membranesEngine sealsMethods of productionMelting point

A sliding element having a sliding surface, wherein a substrate forming the sliding surface is formed with a resin layer, the resin layer has a plurality of porous parts on its surface, and the porous parts are impregnated with a fluorinated oil. Preferably, the resin layer contains a first resin and a second resin having a melting point higher than that of the first resin, and the porous parts of the resin layer are formed by heating the resin layer at a temperature of at least the melting point of the first resin and less than the melting point of the second resin, and exposed at the surface of the resin layer by grinding the resin layer.

Owner:EAGLE INDS

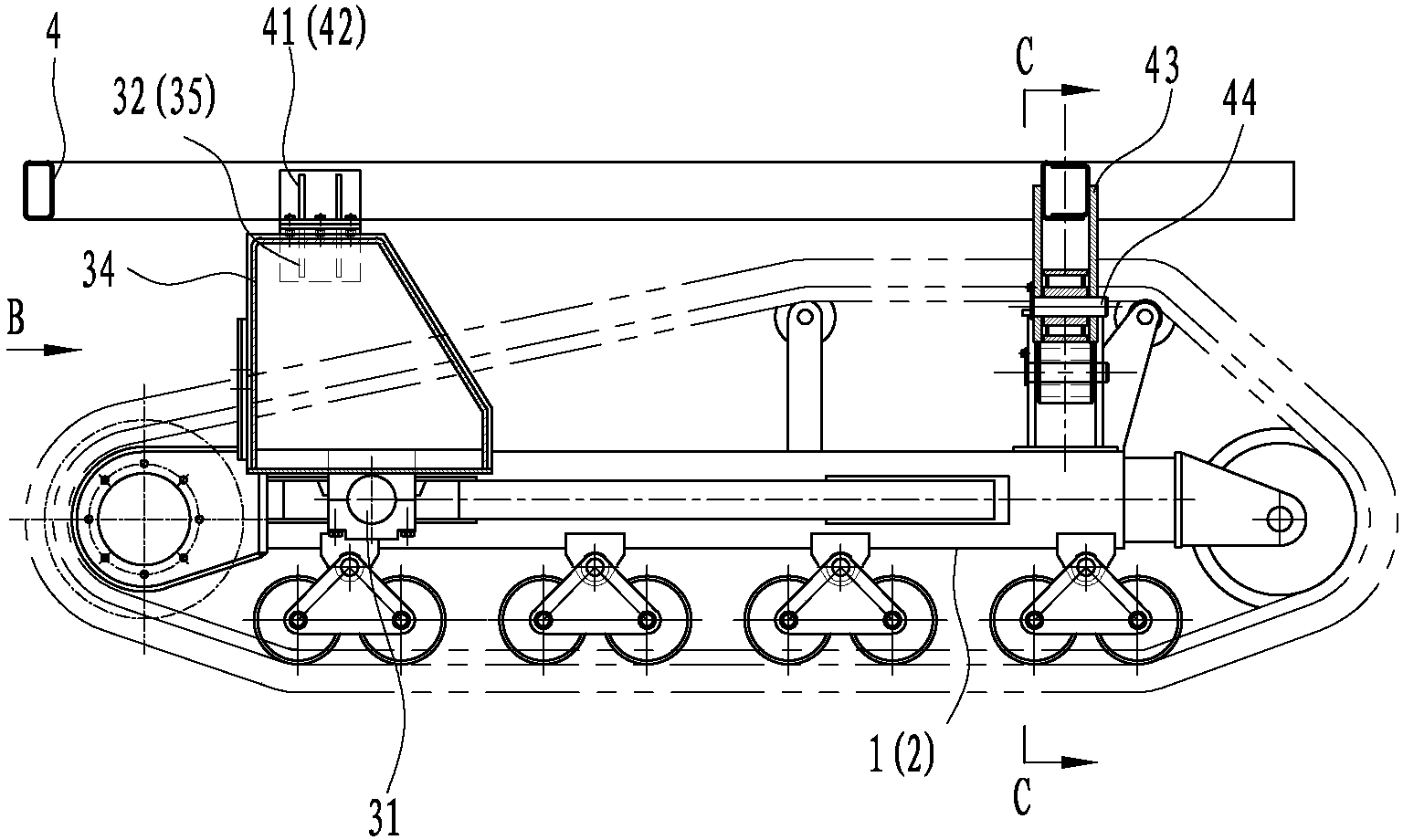

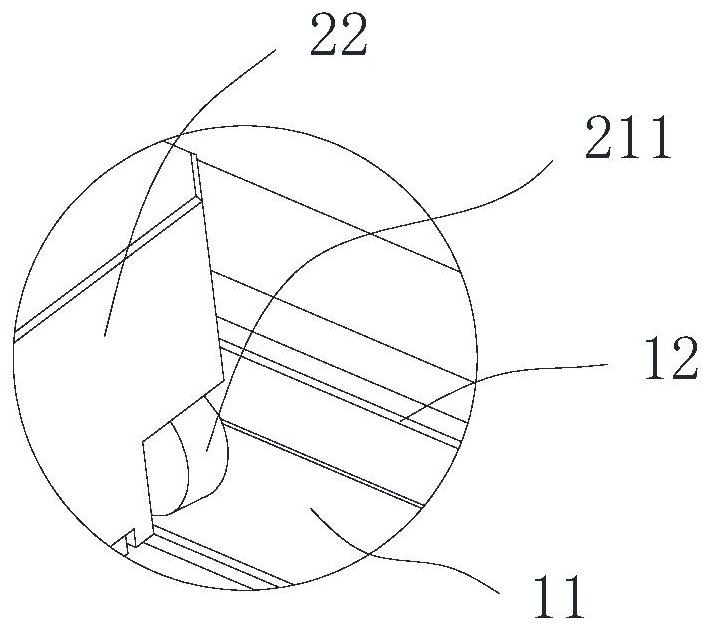

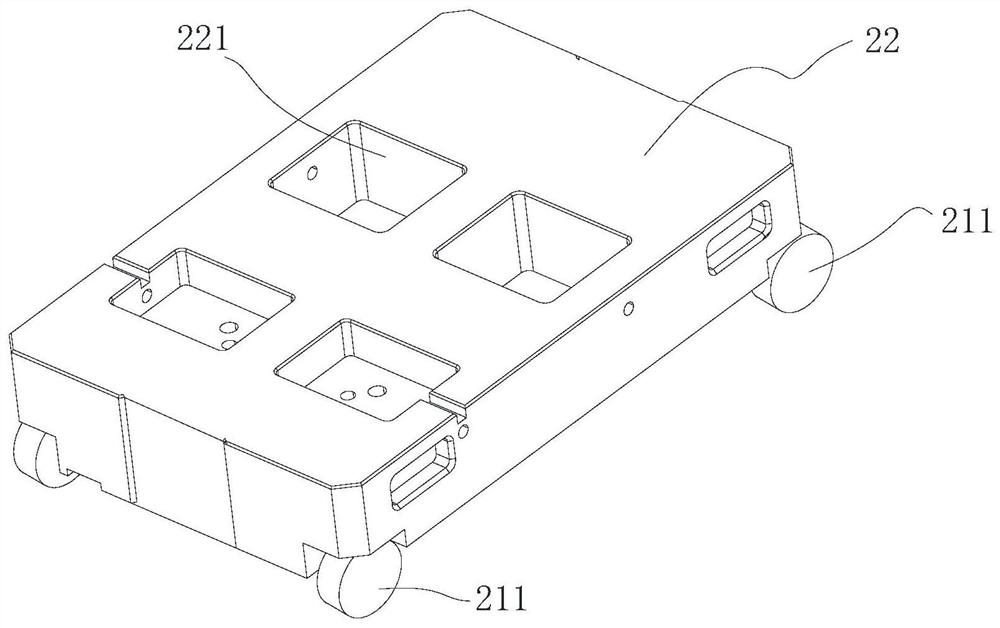

Caterpillar track chassis of sandbeach cleaning trolley

InactiveCN103395453ARealize terrain-following drivingReduce vibrationEndless track vehiclesFuel supplyTerrainFuel tank

The invention discloses a caterpillar track chassis of a sandbeach cleaning trolley. The caterpillar track chassis of the sandbeach cleaning trolley comprises a left caterpillar track rack, a right caterpillar track rack, a fuel tank, a trolley frame, a balancing beam and dampers, wherein the rear portion of the left caterpillar track rack and the rear portion of the right caterpillar track rack are hinged to the two ends of the fuel tank respectively, the front portion of the left caterpillar track rack and the front portion of the right caterpillar track rack are respectively provided with one damper, and the two ends of the balancing beam are arranged on the dampers on the two sides respectively; the middle of the front of the trolley frame is connected to the middle of the balancing beam, the two sides of the rear of the trolley frame are connected to the two sides of the fuel tank, and therefore the trolley frame are respectively connected with the fuel tank and the balancing beam in a three-point connecting mode. Due to the fact that the rear portion of the left caterpillar track rack and the rear portion of the right caterpillar track rack can swing up and down along shafts on the two side of the fuel tank, the left caterpillar track rack and the right caterpillar track rack can achieve terrain-simulating driving, vibration of the trolley is reduced, and the driving speed is greatly improved; besides, due to the fact that the fuel tank is arranged below the trolley frame, the mass center height of the whole trolley is lowered, and loads of the trolley frame can be reduced.

Owner:XIAMEN UNIV OF TECH

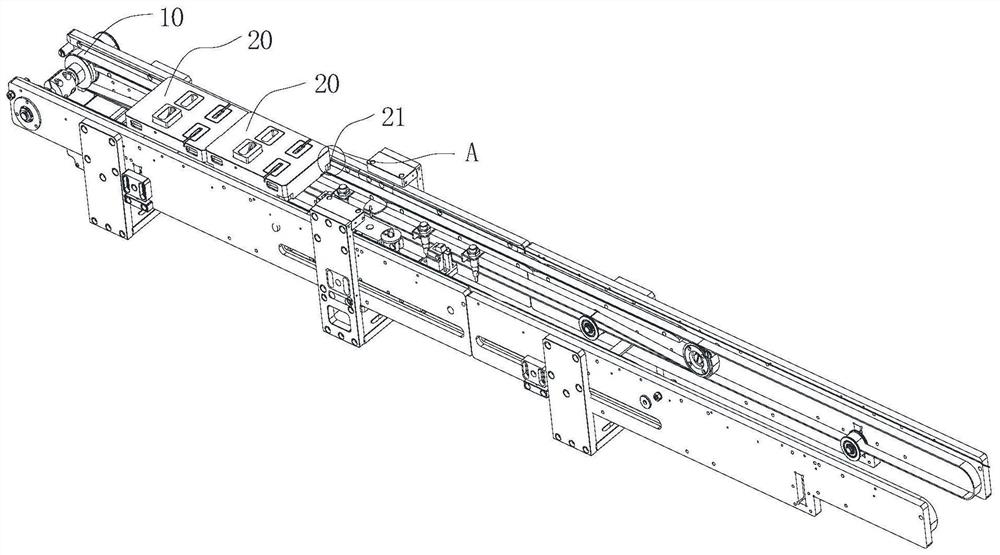

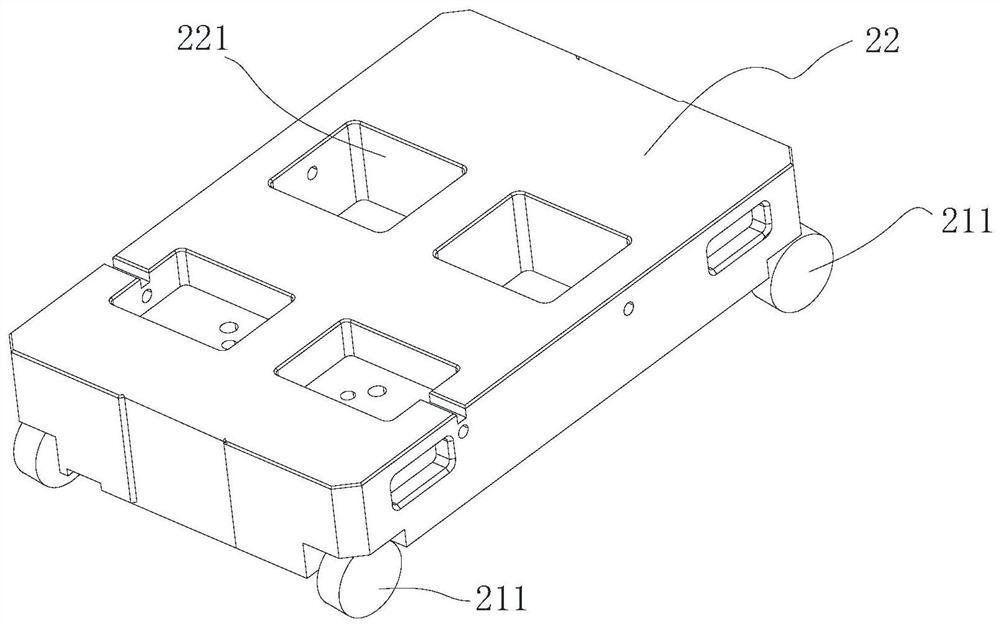

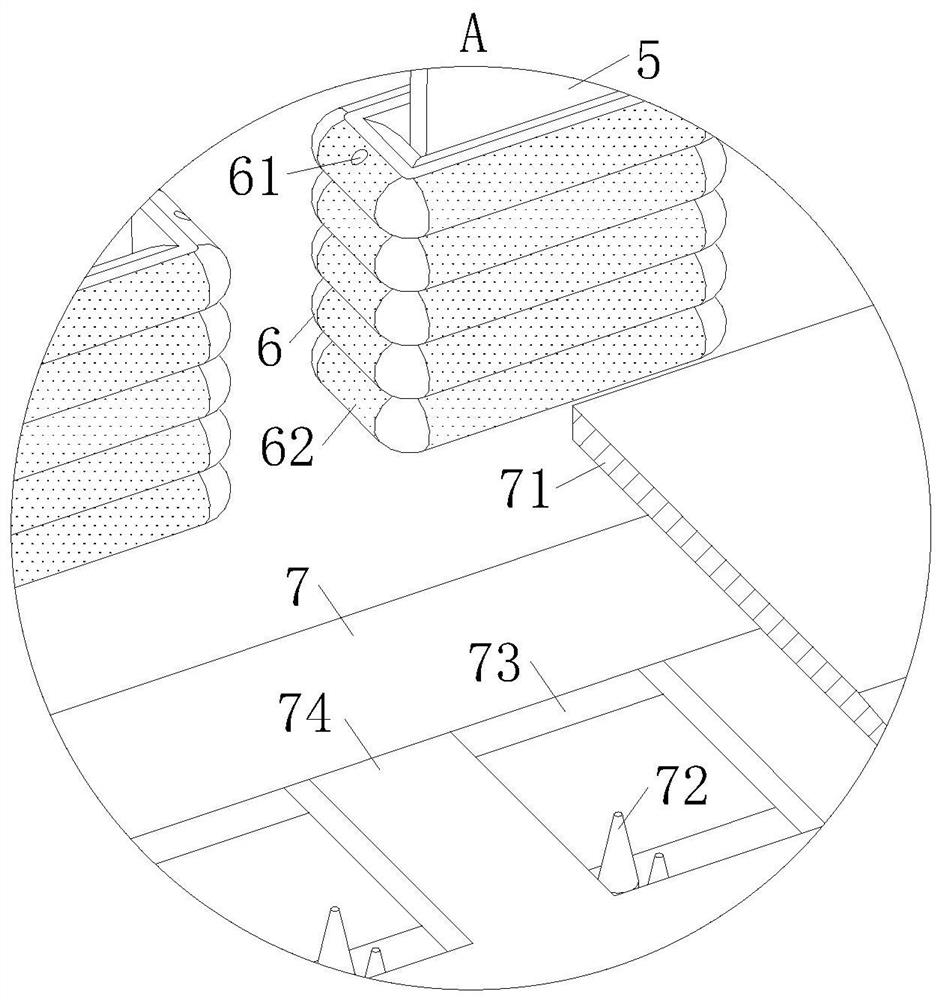

Conveyor belt system and conveyor belt control method

ActiveCN113173395APrevent falling offGood stabilityControl devices for conveyorsAutomotive engineeringSmart control

The invention is applicable to the technical field of intelligent adjustment control systems, and provides a conveyor belt system and a conveyor belt control method. The conveyor belt system comprises a control part, a conveyor belt assembly and carriers, wherein each carrier comprises a damping wheel set, a speed sensing part and a control module. When a certain carrier in a conveyor belt is in clamping stagnation, th said carrier converts sliding friction into rolling friction through the corresponding damping wheel set, so that sliding abrasion between the conveyor belt and the said carrier is avoided, carrier shaking caused by sliding friction force between the conveyor belt and the said carrier can also be prevented, a workpiece on the said carrier is effectively prevented from falling off, and better stability is achieved. According to the conveyor belt system, intelligent production is achieved through matching of the damping wheel sets and the speed sensing parts, the sliding friction between the carrier in clamping stagnation and the conveyor belt can be avoided, the workpiece is prevented from falling off, the running speed of the conveyor belt can be intelligently controlled, large-scale rear-end collision of the carriers is avoided, and system paralysis is prevented.

Owner:SHENZHEN YUANTONG ROBOT AUTOMATION CO LTD

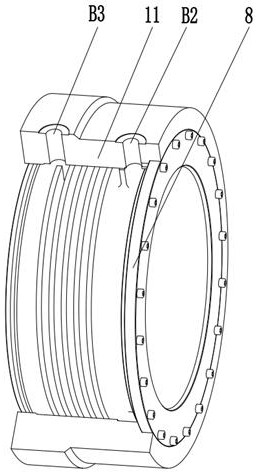

Buffering device for flexible sheet membranes and wastewater filtering module with same

PendingCN108079787AImprove connection efficiencyReduce jitter amplitudeSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisWastewaterSewage

The invention discloses a buffering device for flexible sheet membranes and a wastewater filtering module with same, which comprise a positioning ring, wherein a shock-absorbing ring sheathes the sidewall of the positioning ring, the axis of the shock-absorbing ring is concentric with the axis of the positioning ring, and elastic parts are arranged on the end surfaces of the shock-absorbing ring.On a water-permeable pipe, a flexible sheet membrane located in between is fixed and clamped by two adjacent positioning rings, so the positioning ring is located between two adjacent flexible sheet membranes; and moreover, the ends, which are far from the shock-absorbing ring, of the elastic parts are in contact with the corresponding flexible sheet membrane. When the flexible sheet membrane shakes, due to the arrangement of the elastic parts, the shake amplitude of the portion, which is close to the positioning rings, of flexible sheet membrane is decreased and the shaking of the flexible sheet membrane is buffered, consequently, the stress applied on the portion, which is clamped by the positioning rings, of the flexible sheet membrane is decreased, the strength quality of the clamped portion of the flexible sheet membrane is increased, the flexible sheet membrane can smoothly filter water, and the tightness between the positioning rings and the flexible sheet membrane is increased.

Owner:中欧兴华膜技术(成都)有限公司

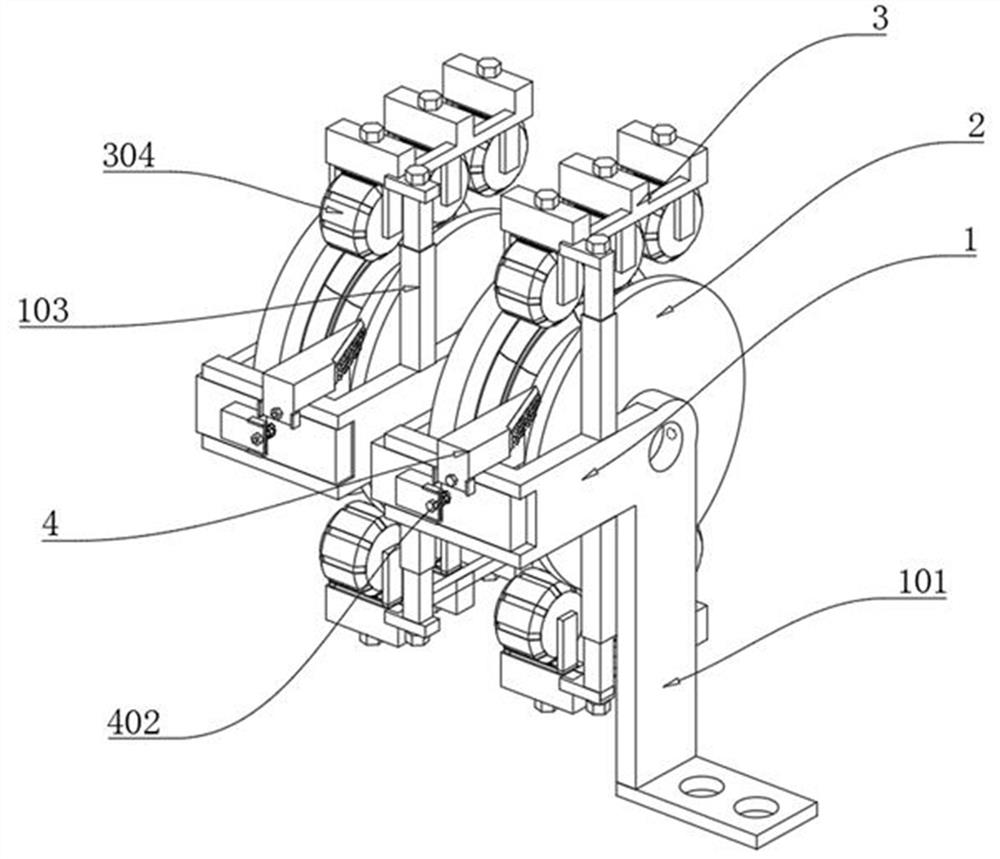

Chip fixing device

ActiveCN110676210AAvoid sliding wearEasy to clamp and fixSemiconductor/solid-state device manufacturingElectric machineryElectrical and Electronics engineering

The invention discloses a chip fixing device, which comprises a platform, wherein the platform is provided with a supporting frame, the supporting frame is in the shape of a Chinese character 'fang',two ends of an opening of the supporting frame are in transmission connection with clamping assemblies, the clamping assembly comprises a driving structure and two fixing plates arranged at the opening of the supporting frame, the opposite side surfaces of the two fixing plates are provided with clamping grooves, a first distance detection sensor and a second distance detection sensor are respectively arranged in the two clamping grooves, a sliding groove is formed in the platform, a motor is arranged at the end part of the sliding groove, the output end of the motor is connected with a lead screw, the lead screw is in threaded connection with a ball, the upper end of the ball is connected with the supporting frame, the lower end of the ball is connected with a sliding block slidably connected in the sliding groove, and the driving structure drives the two fixing plates to move oppositely or reversely. According to the chip fixing device, the two fixing plates can clamp and fix a chipconveniently, the chip can be effectively prevented from sliding and being abraded on the platform in the clamping process, and the quality of the chip fixing efficiency can be improved conveniently.

Owner:深圳市晨兴达电子有限公司

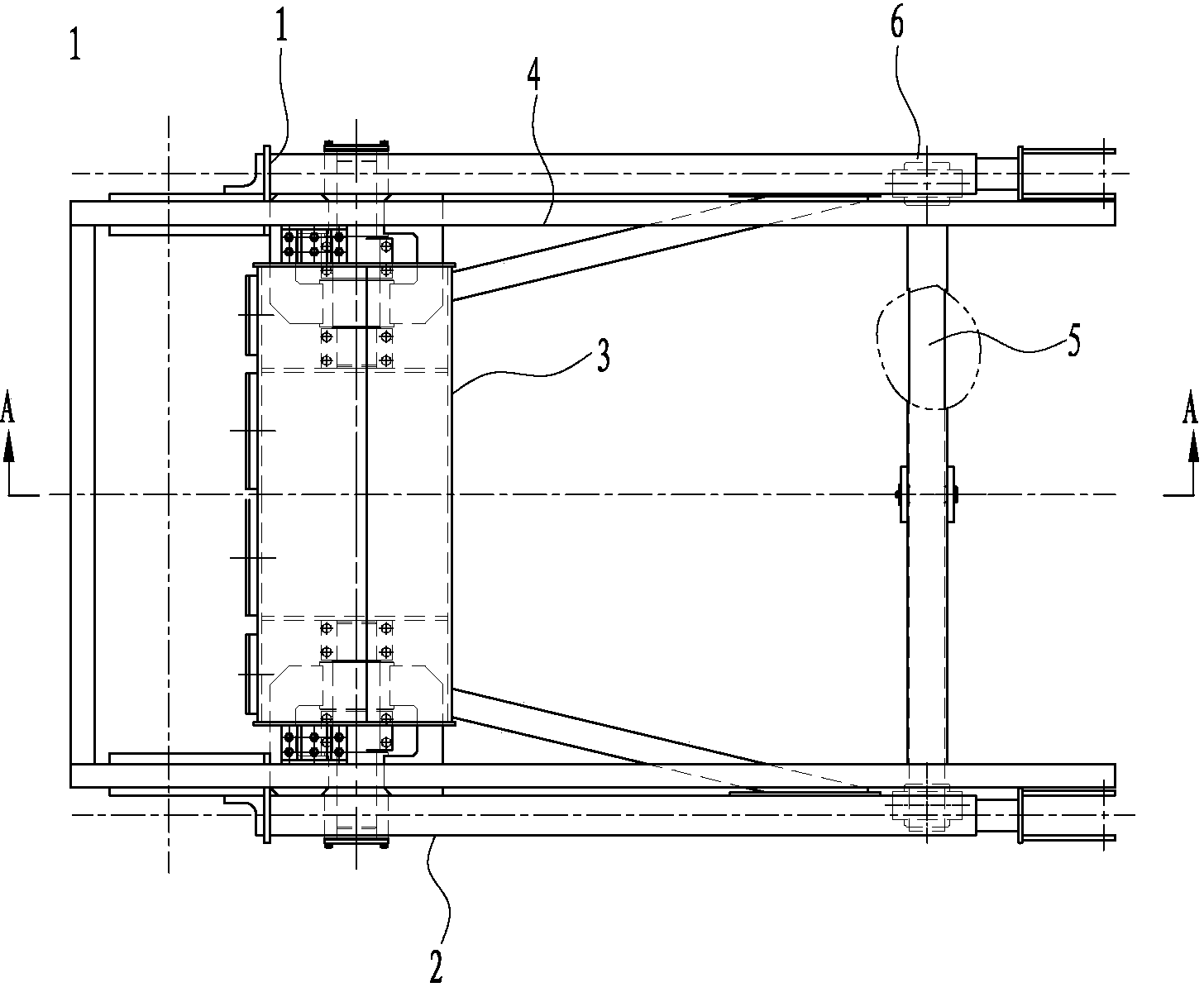

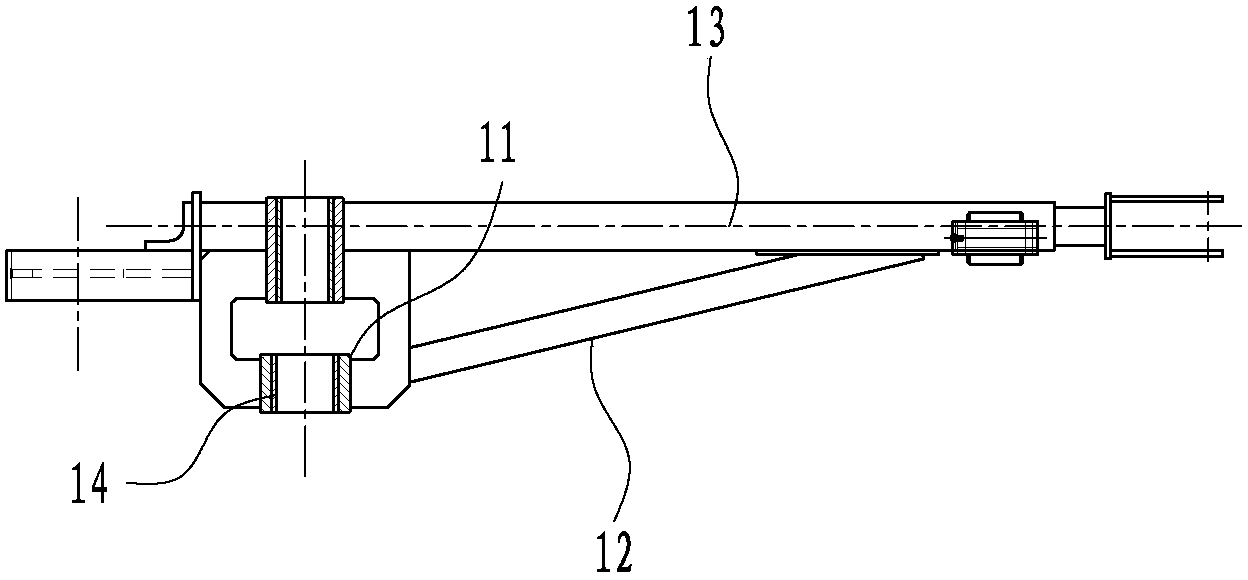

Double front axle structure with lifting axle for heavy goods vehicle

The invention relates to a double-front-axle structure with a lifting axle for a heavy truck. The double-front-axle structure comprises a first front axle, a second front axle, a first front-axle steering pull rod assembly, steering-machine steering knuckle arms, first front-axle steel plate springs, second front-axle lifting air bags, air-bag springs, second front-axle lifting brackets, second front-axle lifting cables and second front-axle steel plate springs. According to the double-front-axle structure disclosed by the invention, through the structural design of the second front-axle lifting air bags, the second front-axle lifting brackets and the second front-axle lifting cables, and through the lifting of the second front-axle lifting air bags, second front-axle tires are separated from a road surface, and the abrasion of the tires is reduced. When the heavy truck turns, the first front axle and the second front axle simultaneously turn, so that the phenomenon that because a second front axle cannot turn, sliding abrasion is caused is avoided. Through the structural design of the first front-axle steel plate springs, the second front-axle steel plate springs and the air-bag springs, the dead weight of the vehicle is effectively reduced.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Conveyor belt system and conveyor belt control method

ActiveCN113173395BIntelligent control of running speedAvoid massive rear-endControl devices for conveyorsRear-end collisionControl system

This application is applicable to the technical field of intelligent adjustment control systems, and provides a conveyor belt system and a conveyor belt control method. The conveyor belt system includes a control part, a conveyor belt assembly, and a carrier. If a carrier in the conveyor belt is stuck, the carrier of this application will convert sliding friction into rolling friction through the damping wheel set, thereby avoiding sliding wear between the conveyor belt and the carrier, and also preventing friction between the conveyor belt and the carrier. The shaking of the carrier caused by sliding friction can effectively prevent the workpiece on the carrier from falling off, and has better stability. Moreover, the conveyor belt system of the present application utilizes the cooperation of the damping wheel set and the speed sensing part to realize intelligent production, which can not only avoid sliding friction between the stuck carrier and the conveyor belt, prevent workpieces from falling, but also intelligently control the operation of the conveyor belt speed, to avoid large-scale rear-end collisions of vehicles, and to prevent system paralysis.

Owner:SHENZHEN YUANTONG ROBOT AUTOMATION CO LTD

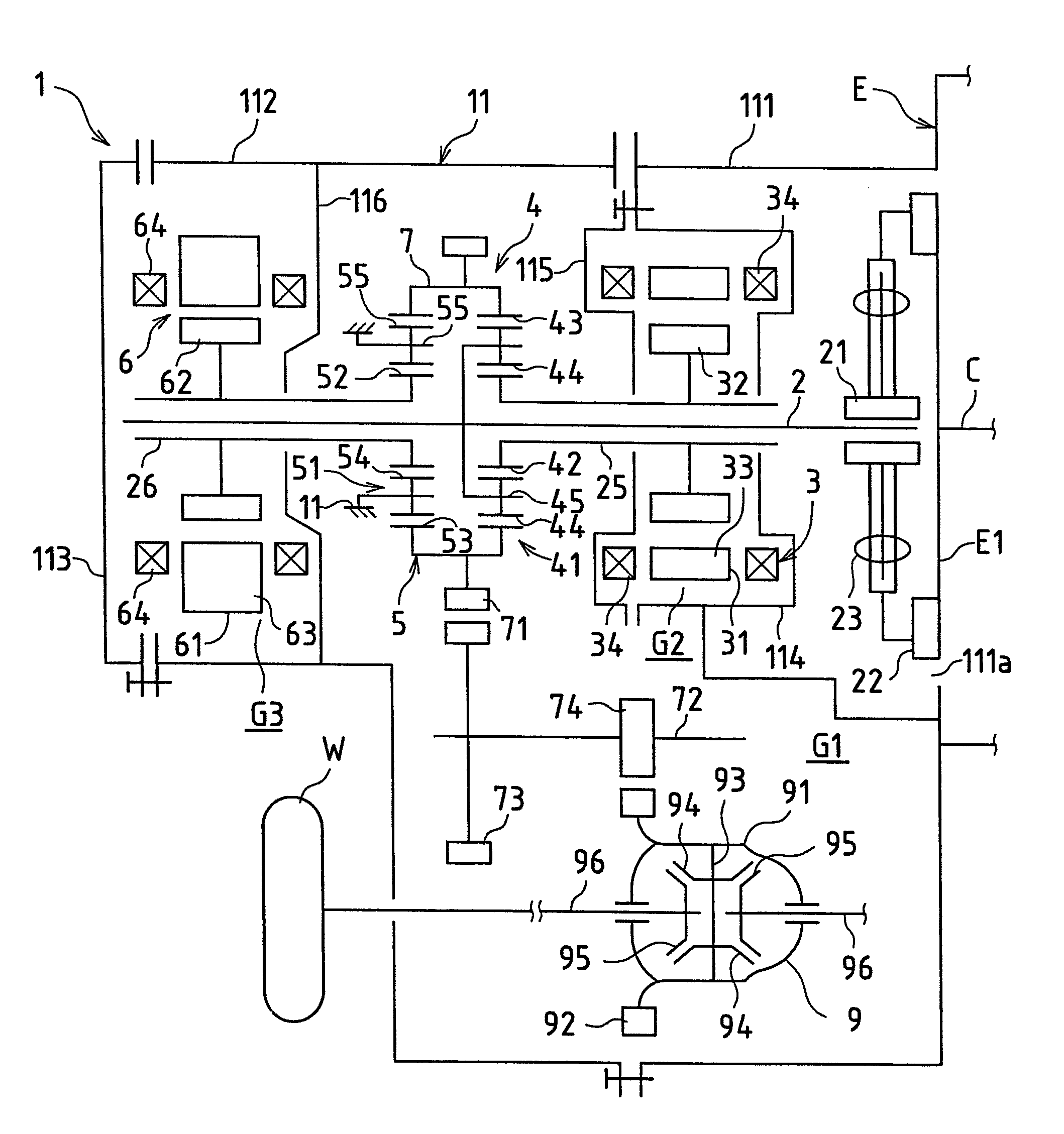

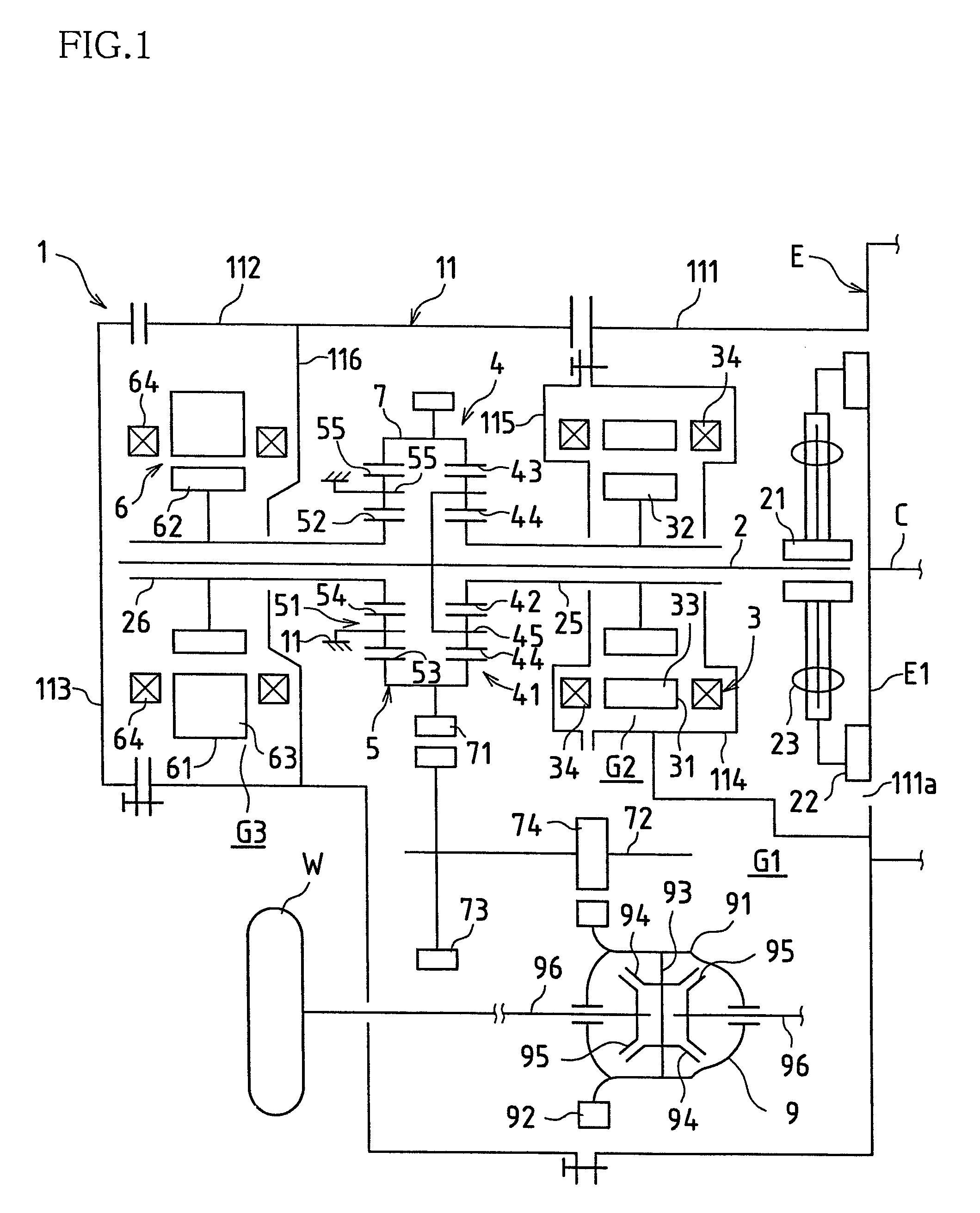

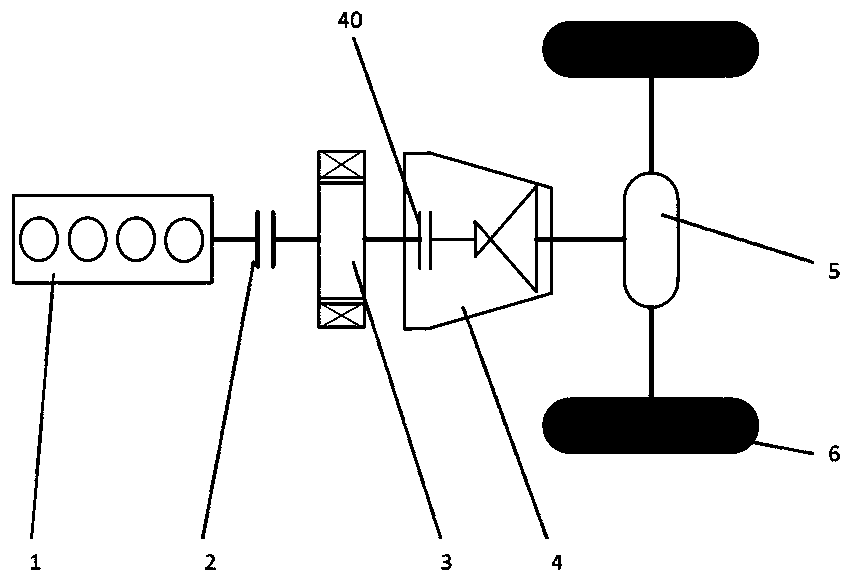

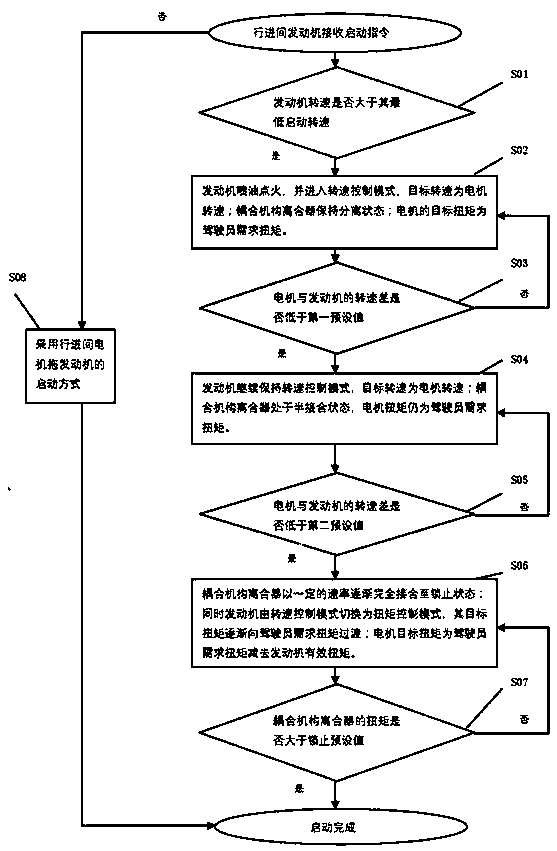

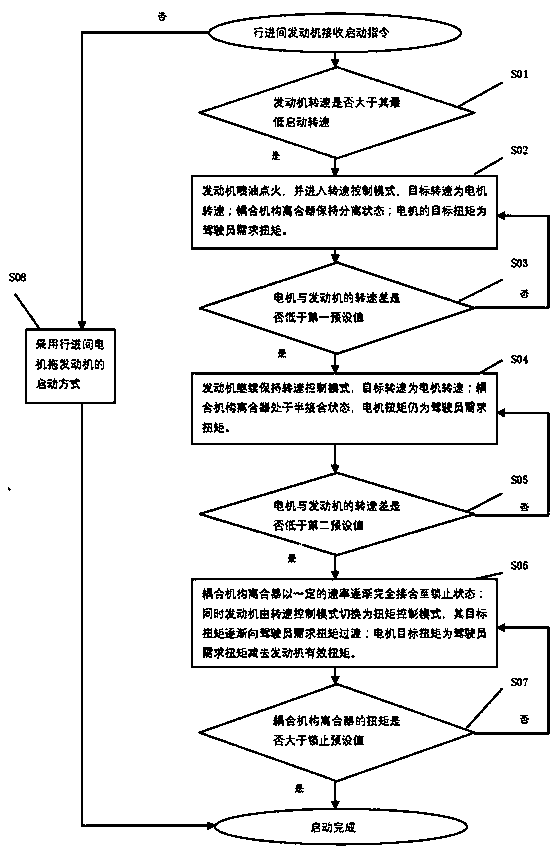

A method for controlling engine startup of a hybrid electric vehicle

The invention relates to a hybrid electric vehicle engine starting control method. When an engine receives a starting instruction during forwarding, if the rotation speed of the engine is larger thanthe minimum starting rotation speed of the engine, the engine sprays fuel for ignition and enters a rotation speed control mode, wherein the target rotation speed is the rotation speed of a motor, a coupling mechanism clutch remains a separated state, and the target torque of the motor is the demand torque of a driver. When the rotation speed difference between the motor and the engine is lower than a first preset value, the engine continues to maintain the rotation speed control mode, and the coupling mechanism clutch is in a semi-engaged state. When the rotation speed difference between themotor and the engine is lower than a second preset value, the coupling mechanism clutch is gradually fully-engaged to be in a locked state according to a certain rate; meanwhile, the engine is switched from the rotation speed control mode to the torque control mode, and the target torque of the engine is gradually changed to the demand torque of the driver. After the torque of the coupling mechanism clutch is greater than a preset lock value, the starting process is finished. Towing of the motor is not needed, the engine is started, and the starting time of the engine is shortened while the smoothness is ensured.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

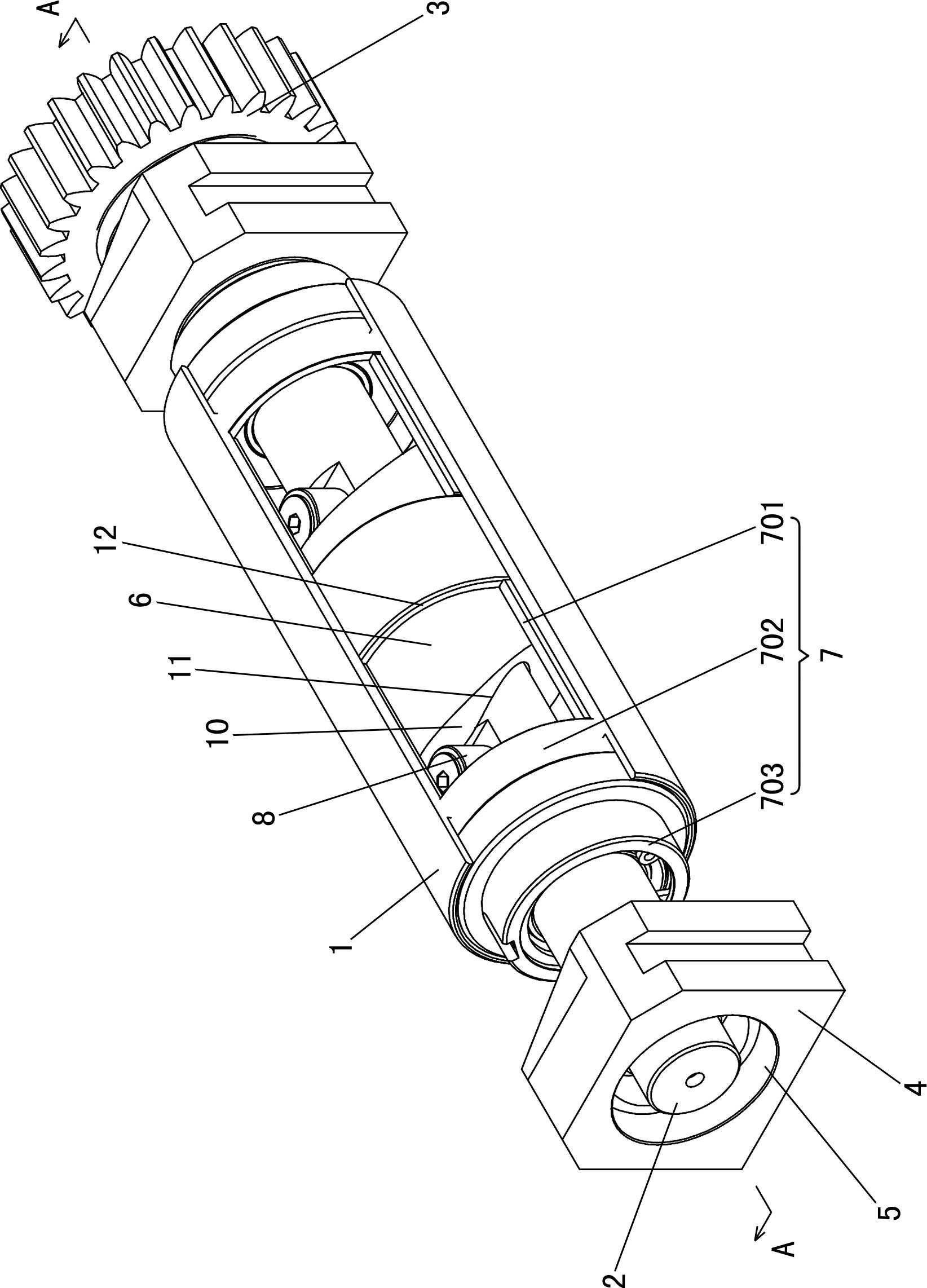

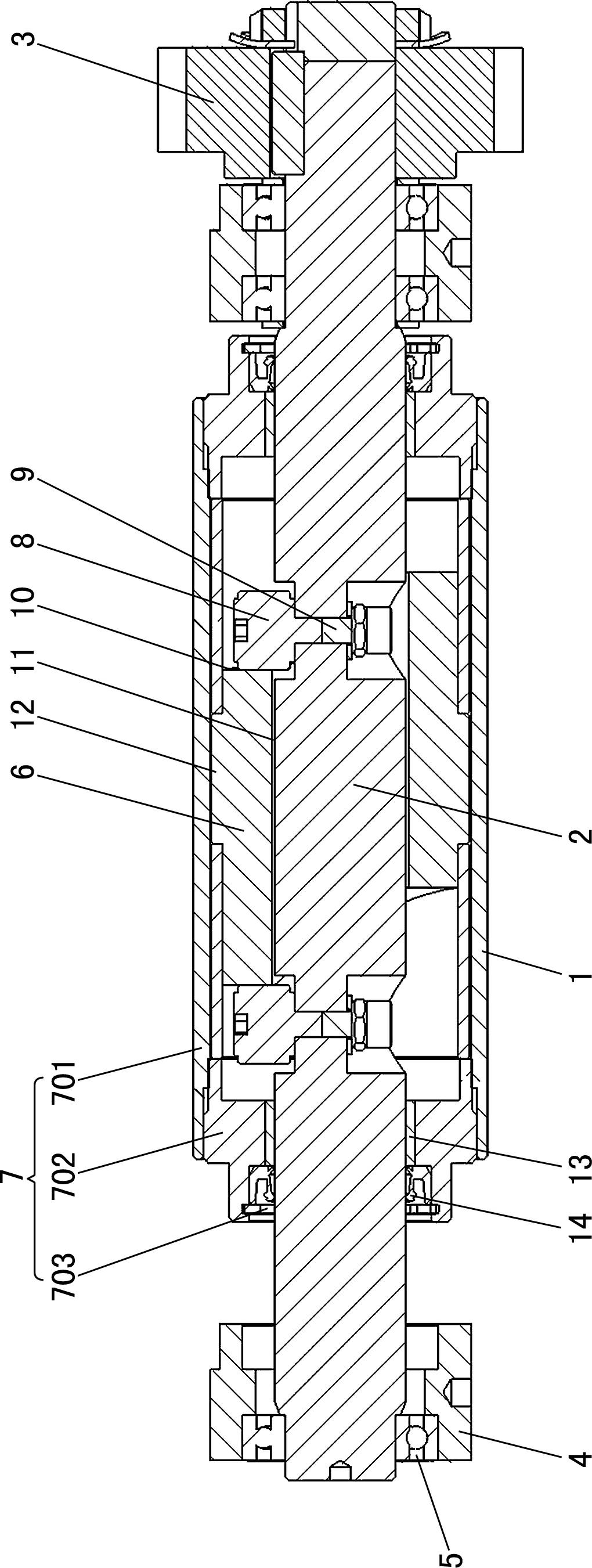

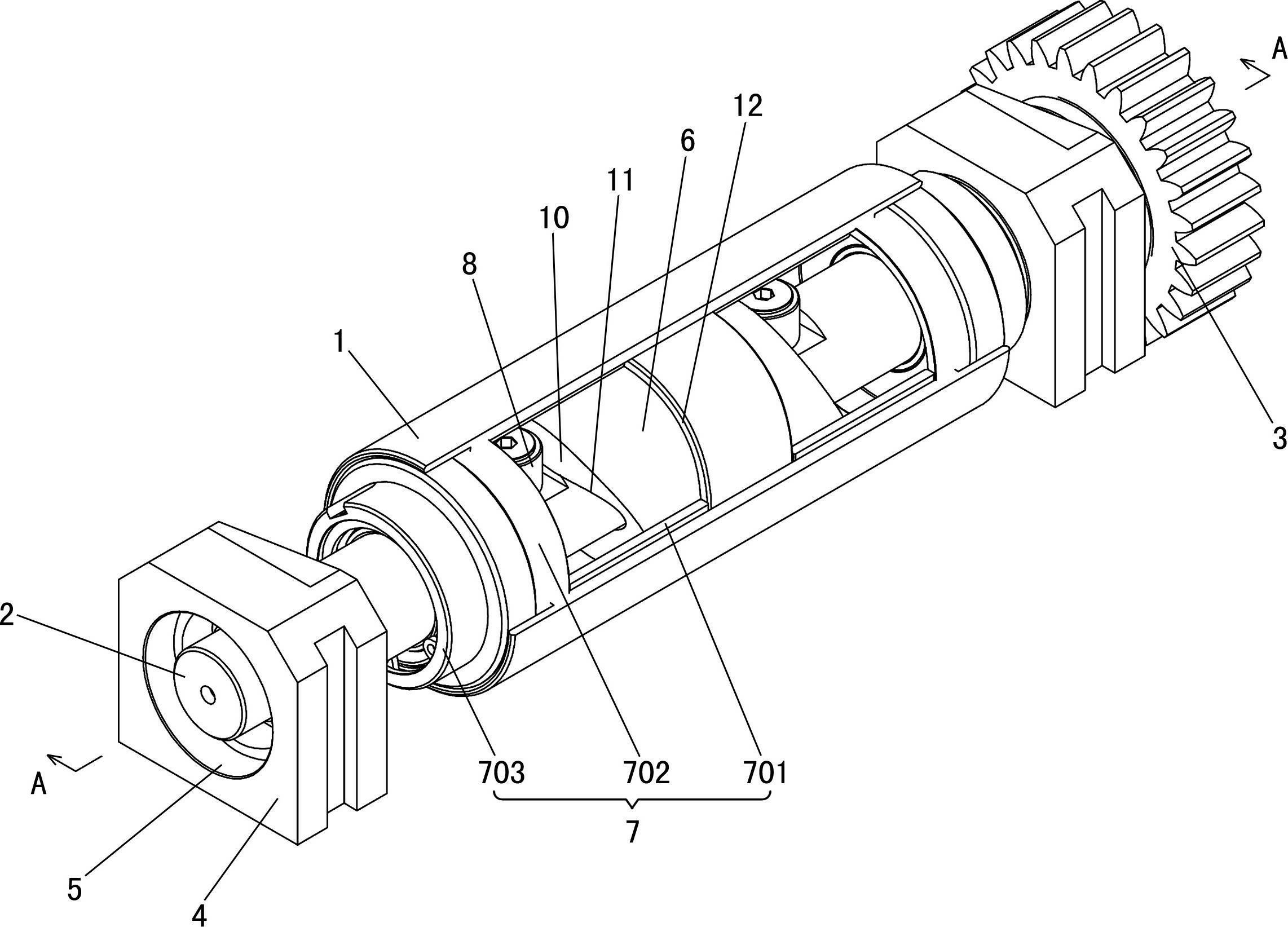

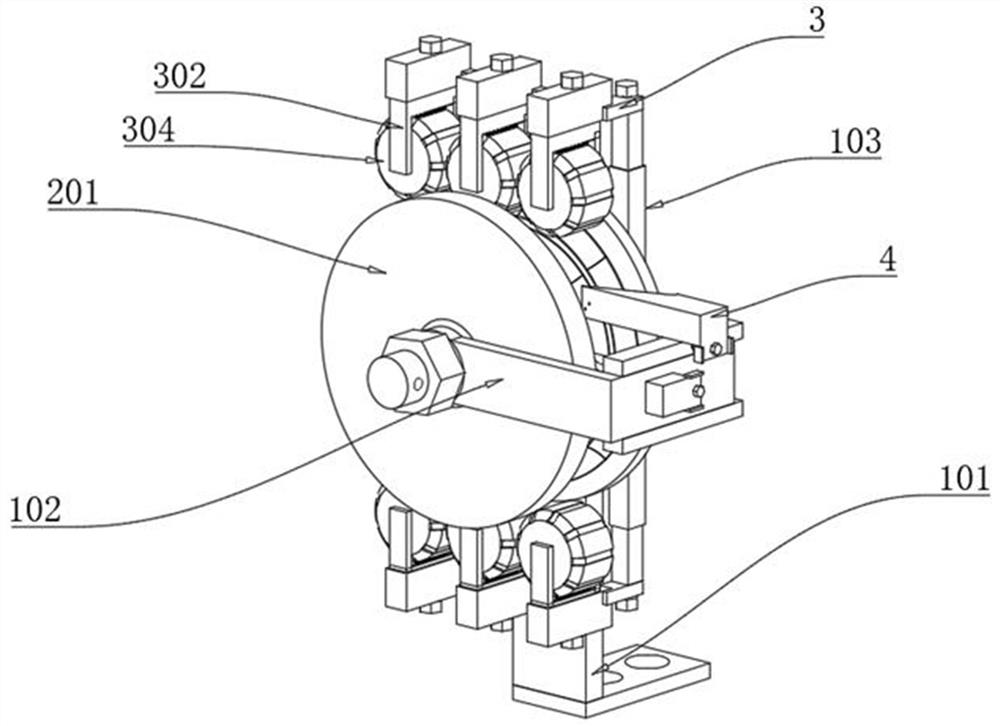

Ink oscillating device for offset machine

The invention relates to an ink oscillating device for an offset machine, comprising an ink oscillating rod, an ink oscillating rod rotating shaft, an ink oscillating gear, two bearing pedestals and two bearings. The ink oscillating device for the offset machine is characterized by further comprising an end-face cylindrical cam, a fastening mechanism, two cam rollers and two roller connecting shafts. The end-face cylindrical cam is provided with a round sliding through hole in the axis direction; the ink oscillating rod rotating shaft is arranged in the round sliding through hole; the cylindrical surface of the end-face cylindrical cam is connected with the inner side wall of the ink oscillating rod through a fastening mechanism; the two cam rollers are arranged on the ink oscillating rod rotating shaft through the two roller connecting shafts and are located at the two ends of the end-face cylindrical cam; and the two cam rollers are in contact match with the corresponding end surfaces. The ink oscillating device for the offset machine has a simpler and compacter structure; the ink oscillating gear cannot slide on the shaft to wear, so that the transmission precision and the service life of the ink oscillating gear cannot be affected, and the ink oscillating gear has longer service life; and the ink oscillating amount of the ink oscillating rod can be adjusted conveniently by adjusting the installation position of the cam rollers on the roller connecting shafts.

Owner:汕头市东源轻工机械厂有限公司

An electric clothes dryer

ActiveCN111271690BAvoid shakingAvoid sliding wearMechanical apparatusLighting elementsLight guideElasterell

The invention discloses an electric clothes drying machine, which belongs to the technical field of clothes drying machines. In the existing solutions, in order to avoid scratches and wear of the light guide plate components, they all adopt a split assembly structure, and the light guide components are fixed through independent pressure frames and chassis, which has a complicated structure and high manufacturing cost, and a corresponding connection structure needs to be set up. , leading to complex assembly and low assembly efficiency. After continuous exploration and testing, the present invention changes the existing sequentially stacked fixed connection method into a plug-in connection method, breaks the technical prejudice that the existing flat panel lamp must be assembled separately, and sets an integrally formed and hemmed hemming At the same time, the elastic parts are assembled in the concave cavity of the hemming piece to realize the wear-free insertion assembly of the light guide component on the hemming piece; it can effectively avoid the sliding wear between the panel and the light guide component, and further panel insertion is completed Finally, the elastic member can effectively limit the position of the panel, avoiding the shaking of the panel, the structure is simple, the manufacturing cost is low, the assembly is convenient, and the concept is ingenious.

Owner:AUPU HOME STYLE CORP LTD

Other side tool support base and/or other side tool post mounted to casting breaking apparatus, and bearing of the other side tool support base

ActiveUS20100059613A1Avoid wear and tearAvoid sliding wearBearing componentsGrain treatmentsLower faceSliding contact

In a background art, one side and other side tool apparatus (casting breaking apparatus) upper and lower faces of which are opened are constituted by one side and other side tool support bases, one side and other side tool posts provided at the one side and the other side tool support bases, a number of pieces of one side and other side tools in a ridge shape projected from the one side and the other side tool posts respectively in a zigzag shape and brought into a fitting relationship, and movable means (cylinder) for making the other side tool post movable, and characterized in that sliding faces provided at both sides of the other side tool support base and / or the other side tool post are advanced and retreated along an inner face of a side plate. Further, explaining an operation (method) of crushing and breaking of the casting breaking apparatus, in retreating the other side tool post, a casting waste is thrown from a throwing opening (throwing port) formed between the other side tool post and the one side tool post, and the casting waste is broken by utilizing a fitting relationship between the other side tool of the other side tool post advanced by the cylinder and the one side tool of the one side tool post. The sliding face of the other side tool post is advanced or retreated to be brought into sliding contact with the sideplate of the breaking apparatus. By the advance, the casting waste thrown to the casting breaking apparatus is broken, and by the retreat, a broken piece of the broken casting waste is discharged from a discharge port formed between the other side tool post and the one side tool post by natural dropping.Further, according to the kind of apparatus, the other side tool post is brought into sliding contact with the side plate when the other side tool post is made to be movable, and there is a probability of generating wear at the face to be slid (sliding face). Further, when a particle, or a small piece of the casting waste invades a gap between the other side tool post and the side plate, a problem of accelerating a degree of the wear is conceivable.In view of the above-described, according to the invention, by constituting other side tool support base and / or other side tool post mounted to a casting breaking apparatus constructed by a constitution in which both sides of other side tool support base and / or other side tool post are formed with sliding faces brought into sliding contact with both side plates, the sliding face is formed with a cut recess streak reaching upper and lower sides of the sliding face, the cut recess streak is subjected to overlay welding, and an overlay weld streak piece substantially in flush with the sliding face is formed by polishing means for making an overlayer of the overlay welding substantially in flush with the sliding face, it is intended to make wear of the sliding face as less as possible, or, when a particle or a small piece of the casting waste invades a gap between the other side tool support base and / or the other side tool post and the side plate, a degree of wear is accelerated, and therefore, it is intended to avoid the wear.Further, according to the invention, an axially fixed portion provided at the side plate of supporting the other side tool support base is constituted by a bearing provided at the side plate, a thin-walled ring-like metal provided at an inner peripheral face of the bearing, and dust seals provided at both ends of the inner peripheral face of the bearing, and it is intended to protect the axially fixed portion of the other side tool support base on a movable side applied with a load, or swiftly execute repair in failure.

Owner:OKUYA YASUAKI

Adsorption longitudinal glass breaking and separating device

ActiveCN108099024BImprove product qualityAvoid sliding wearWorking accessoriesGlass severing apparatusVacuum pumpingEngineering

The invention provides an adsorption type longitudinal glass breaking and separating device. The adsorption type longitudinal glass breaking and separating device includes: a support platform and a lifting mechanism for driving the supporting platform to lift; a glass breaking mechanism arranged on the center of the supporting platform; two groups of glass separating mechanisms which are symmetrically distributed on two sides of the glass breaking mechanism; two groups of adsorption mechanisms which are symmetrically distributed on two sides of the glass breaking mechanism, wherein each adsorption mechanism includes an adsorption bracket, a vacuum-pumping system and a vacuum breaker valve, the adsorption bracket is fixedly connected to a movable platform, a top surface of the adsorption bracket is an adsorption surface contacting glass and has a plurality of adsorption holes, the adsorption holes are connected to the vacuum-pumping system through an adsorption channel, and the vacuum breaker valve is arranged on the adsorption channel. During a whole glass breaking and separating process, the glass does not contact glass conveying rollers, sliding abrasion between a bottom surfaceof the glass and the glass conveying rollers can be avoided, and the production quality of the glass is improved.

Owner:CHINA TRIUMPH INT ENG

Preparation method of isosceles right triangle deep sea aquaculture protection net

ActiveCN114775075AFast assemblyImprove assembly efficiencyClimate change adaptationHeating/cooling textile fabricsPropanoic acidPolyhexamethylene guanidine

The invention provides a preparation method of an isosceles right triangle deep sea aquaculture protection net. The preparation method comprises the four steps of granule mixing, preparation of wires for a protection net, preparation of net pieces and preparation of the protection net. A phthalocyanine green G pigment, an anti-ultraviolet agent UV-327, a polyhexamethylene guanidine grafted modified polypropylene material, tetrakis [beta-(3, 5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester, a fluorescent yellow pigment, white oil and polypropylene granules are used as raw materials, wire drawing is performed after uniform mixing and stirring, bright yellow wires for the protective net are obtained, then wire making is performed, a net piece is woven, and the protective net is prepared. And a protective net is further prepared to finally form the protective net for deep and far sea culture. According to the technical scheme, the strength, protection, pollution prevention, storm resistance, bite resistance and impact resistance of the product are improved, the color warning function is achieved, and consumption reduction and resistance reduction of deep and far sea culture production, healthy growth of cultured fishes and green development of the deep and far sea culture industry are promoted.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Electric clothes air-drying machine

ActiveCN111271690AAvoid shakingAvoid sliding wearMechanical apparatusLighting elementsLight guideEngineering

The invention discloses an electric clothes air-drying machine, and belongs to the technical field of clothes air-drying machines. According to an electric clothes air-drying machine in the prior art,a split type assembly structure is adopted for preventing a light guiding plate assembly from being scraped or abraded, a light guiding assembly is fixed through an edge press frame and a base platewhich are independent from each other, the structure is complex, and the manufacturing cost is high; and furthermore, because a corresponding connecting structure needs to be arranged, assembly is complex, and the assembly efficiency is low. According to the electric clothes air-drying machine obtained after continuous exploration and tests, an existing sequential overlaying fixed connection manner is changed into an insertion connection manner, and the technical prejudice that an existing panel light must be assembled in a split manner is broken; because an integrally formed edge-overturned part with folded edges is arranged, and an elastic part is assembled to a concave cavity of the edge-overturned part, it is implemented that the light guiding assembly is assembled to the edge-overturned part without abrasion in an insertion connection manner, and sliding abrasion between a panel and the light guiding assembly can be effectively avoided; and after further insertion connection of the panel is completed, the panel can be effectively limited by the elastic part so as to be prevented from shaking, the structure is simple, the manufacturing cost is low, assembly is convenient to carry out, and the conception is ingenious.

Owner:AUPU HOME STYLE CORP LTD

Access control system based on face recognition

ActiveCN113781694AReduce collision damageShorten speedIndividual entry/exit registersVibration suppression adjustmentsSimulationCamera module

The invention relates to the technical field of access control, in particular to an access control system based on face recognition. The system comprises a camera module, a sidewalk gate, a road gate and a controller. In the operation process of a community face recognition access control, the situation that a visitor and a vehicle license plate are not recognized at the first attempt often occurs, the visitor and the vehicle need to enter a recognition area again, and the operation efficiency of a face recognition access control system is influenced. In the process in which the vehicle is recognized again, the speed of the vehicle which shifts gears and advance again is low, and if the roadway gate falls down in advance at the moment, the risk of damaging the vehicle can be caused. Therefore, an object entering the access control system is recognized twice through a main recognition unit and an auxiliary recognition unit which are arranged in the camera module, and collision damage caused by a road bar when a vehicle does not leave a barrier gate and descends is reduced by utilizing a damping air bag mounted at the bottom of a vertical rod, so that the operation effect of the access control system based on face recognition is improved.

Owner:ZHUHAI DIGITAL POWER TECH

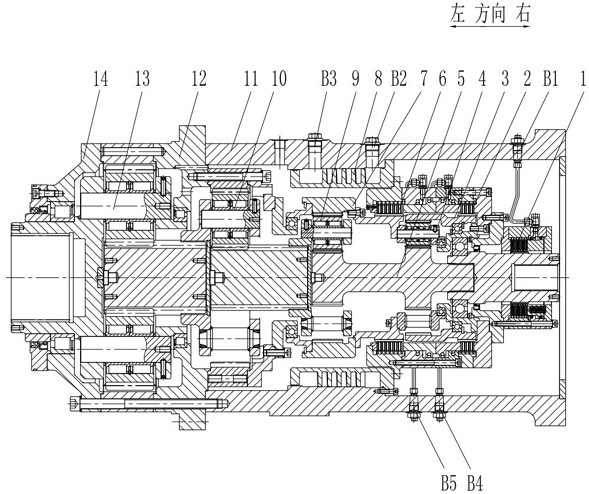

Main drive planetary gear box of hydraulic gear shifting double-speed hard rock heading machine

PendingCN114263712ARealize the constraints on degrees of freedomRealize unrestrictedPortable liftingGear lubrication/coolingClassical mechanicsElectric machinery

The invention provides a hydraulic gear-shifting double-speed hard rock heading machine main drive planetary gear box which is installed between a heading machine main motor and a main drive box, the reduction ratio in a high-speed mode is 30, the reduction ratio in a low-speed mode is 55, mode switching can be directly conducted through control of a hydraulic clutch, and the hydraulic gear-shifting double-speed hard rock heading machine main drive planetary gear box has the advantage of being convenient to switch. And in a low-speed mode, the escape torque of the equipment can be increased by 1.8 times. Practical engineering verifies that the double-speed differential planetary gearbox is mounted on the hard rock heading machine, so that the escape capability of the open type hard rock heading machine under the geological condition of weak and broken surrounding rock can be greatly improved.

Owner:SHANGHAI ZHENHUA HEAVY IND GRP NANTONG TRANSMISSION MACHINERY +1

Solar cell spring test probe

ActiveCN104702211BNo elastic deformationEffective cushioningPhotovoltaic monitoringPhotovoltaic energy generationElectrical resistance and conductanceSpring Test

Owner:陕西众森电能科技有限公司

Cable clamping device for coal mining

PendingCN114572758AImprove compatibilityStable supportFilament handlingCleaning using toolsMining engineeringPulley

The invention provides a cable clamping device for coal mining, and relates to the technical field of coal mining. The main frame body comprises a lower fixing frame, an auxiliary connecting frame, connecting sliding pipes, a screw pipe and a lead screw, the lower fixing frame is fixedly arranged on the lower portion of the main frame body, the auxiliary connecting frame is slidably arranged in the middle of the main frame body, the connecting sliding pipes are fixedly arranged on the upper portion and the lower portion of the main frame body, the screw pipe is fixedly arranged in the middle of the main frame body, and the screw pipe is in threaded connection with the lead screw. The solenoid is arranged on the outer side of the lead screw. A main fixing cone pulley and an auxiliary fixing cone pulley can better support a bent cable, three lower fixing wheels compress a first supporting spring to form a height difference, the device adapts to the arc-shaped bent cable, and the cable is uneven in stress. The problem that the right angle of the edge of the device abuts against the cable, so that the cable is larger in pressure and easier to age and deform is solved.

Owner:丰县源阳商贸有限公司

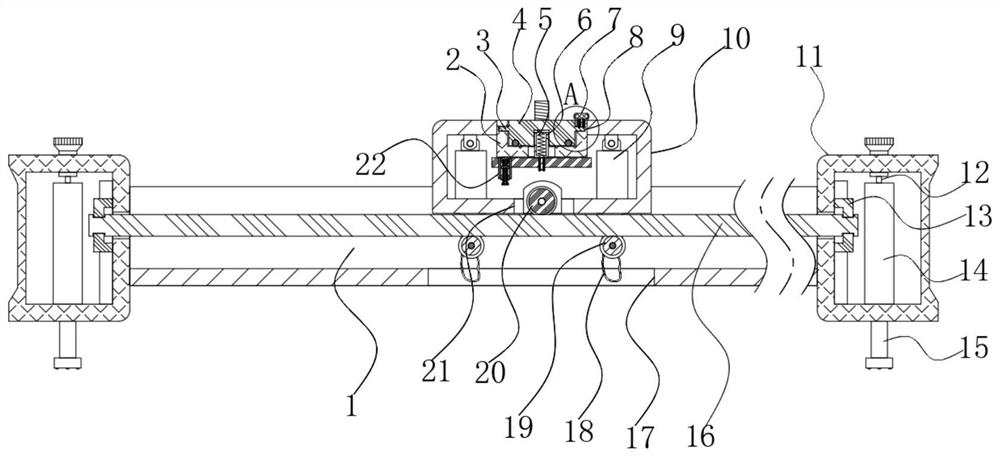

Adjustable camera sliding rail

PendingCN113418115AAvoid sliding wearAdjust the tightnessStands/trestlesStructural engineeringMechanical engineering

The invention belongs to the technical field of camera sliding rails, and particularly relates to an adjustable camera sliding rail. The provided following scheme aims to solving the problem that harsh sounds are generated due to abrasion often caused by hard contact in most horizontal movement and rotation in the prior art. The camera sliding rail comprises a groove-shaped sliding rail with an upward opening and a square tube outer frame slidably connected to the interior of a sliding groove of the groove-shaped sliding rail, end blocks are welded to the two ends of the groove-shaped sliding rail, the same round rod is slidably connected between the two end blocks, two rectangular holes are formed in the position, close to the middle, of the bottom of the square tube outer frame, and telescopic hanging rods are hinged to the positions, located over the rectangular holes, of the inner wall of the top of the square tube outer frame. When the adjustable camera sliding rail is in use, and the square tube outer frame slides on the groove-shaped sliding rail, a lower guide wheel can roll on the surface of the round rod under the action of the telescopic hanging rods, a certain buffering effect is achieved, and therefore, on one hand, sliding abrasion of a certain section often caused by hard contact is avoided, and no harsh metal friction sounds are generated.

Owner:候胖

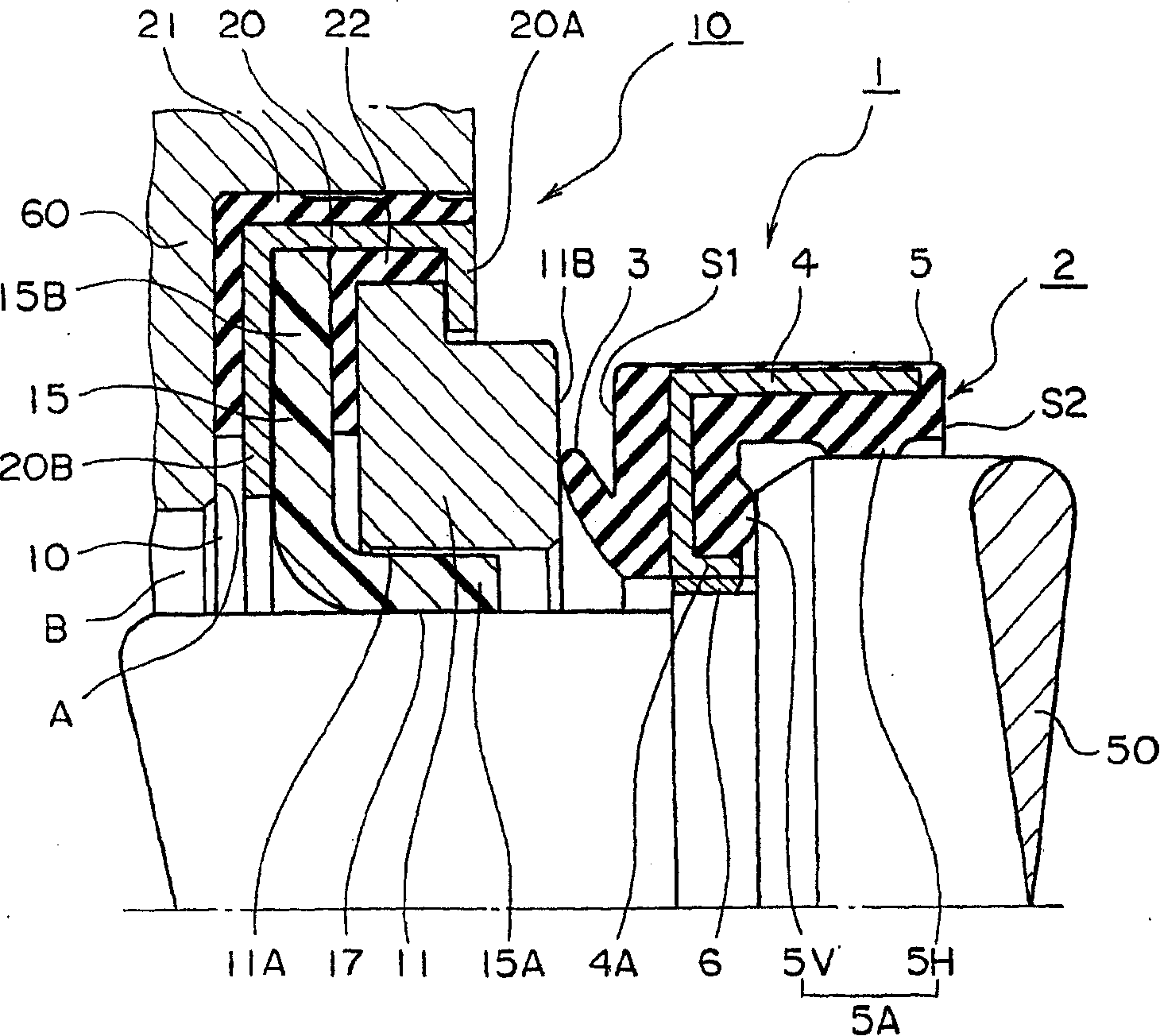

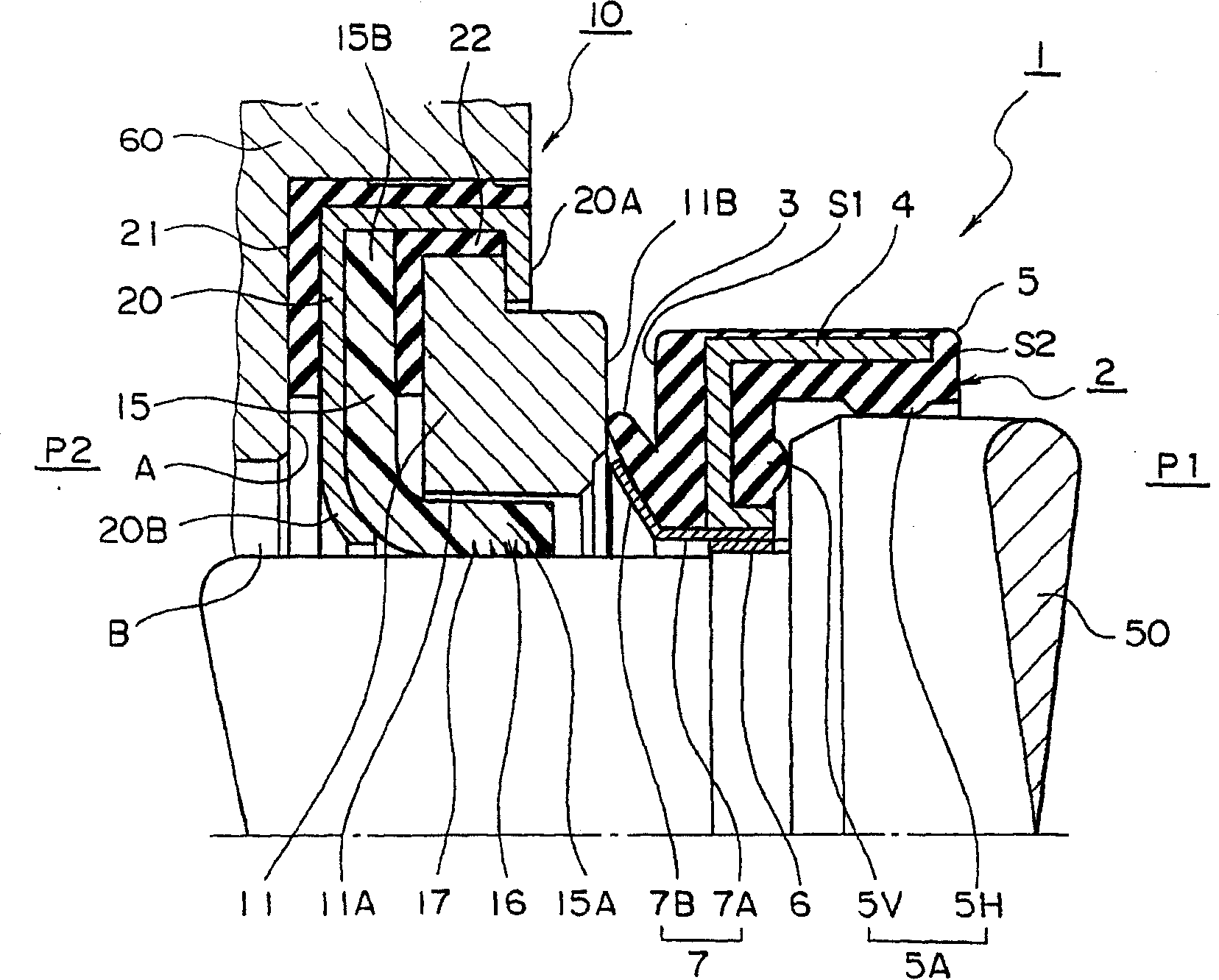

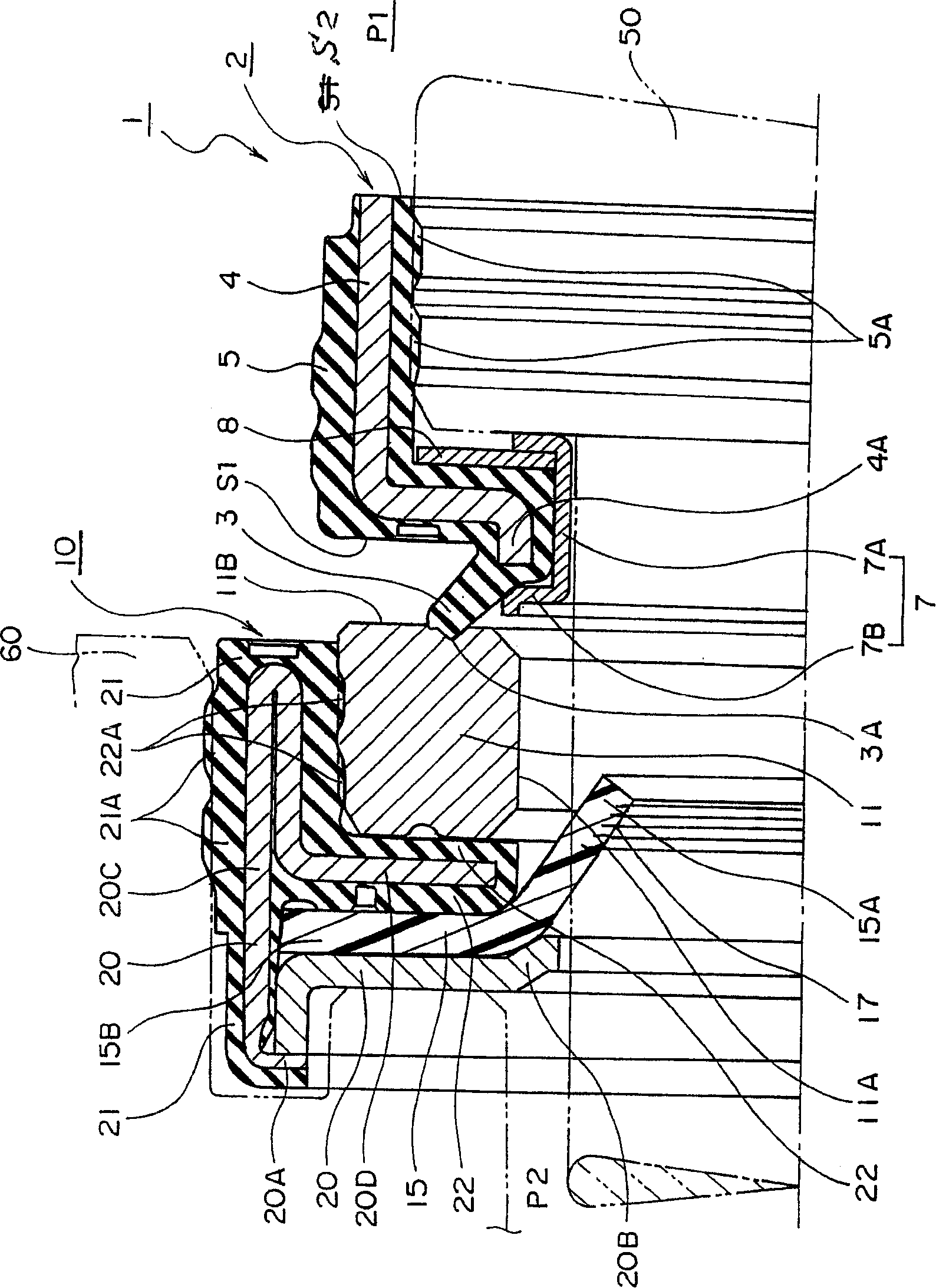

Seal device

A seal device, wherein the contact part of a seal lip (15) with a magnetic part is separated from the contact part of an end face seal (2) with the magnetic part to prevent a material from being softened by the transfer of sliding heating from the seal lip (15) to the end face seal (2) so as to increase a seal performance, a projected lip (3) is extended aslant in outer radial direction and fitted to the seal face (11B) of a sealed ring (11), and a seal contact surface (17) is effectively fitted to a rotating shaft (50) so that the lip part (15A) of the seal lip (15) can seal sealed fluid on the inner peripheral surface (11A) side of the sealed ring (11).

Owner:EAGLE INDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com