Electric clothes air-drying machine

A clothes dryer and electric technology, applied in the field of clothes dryer, can solve the problems of high manufacturing cost, low assembly efficiency, and complicated assembly, and achieve the effects of low manufacturing cost, simple assembly, and reduced structural thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

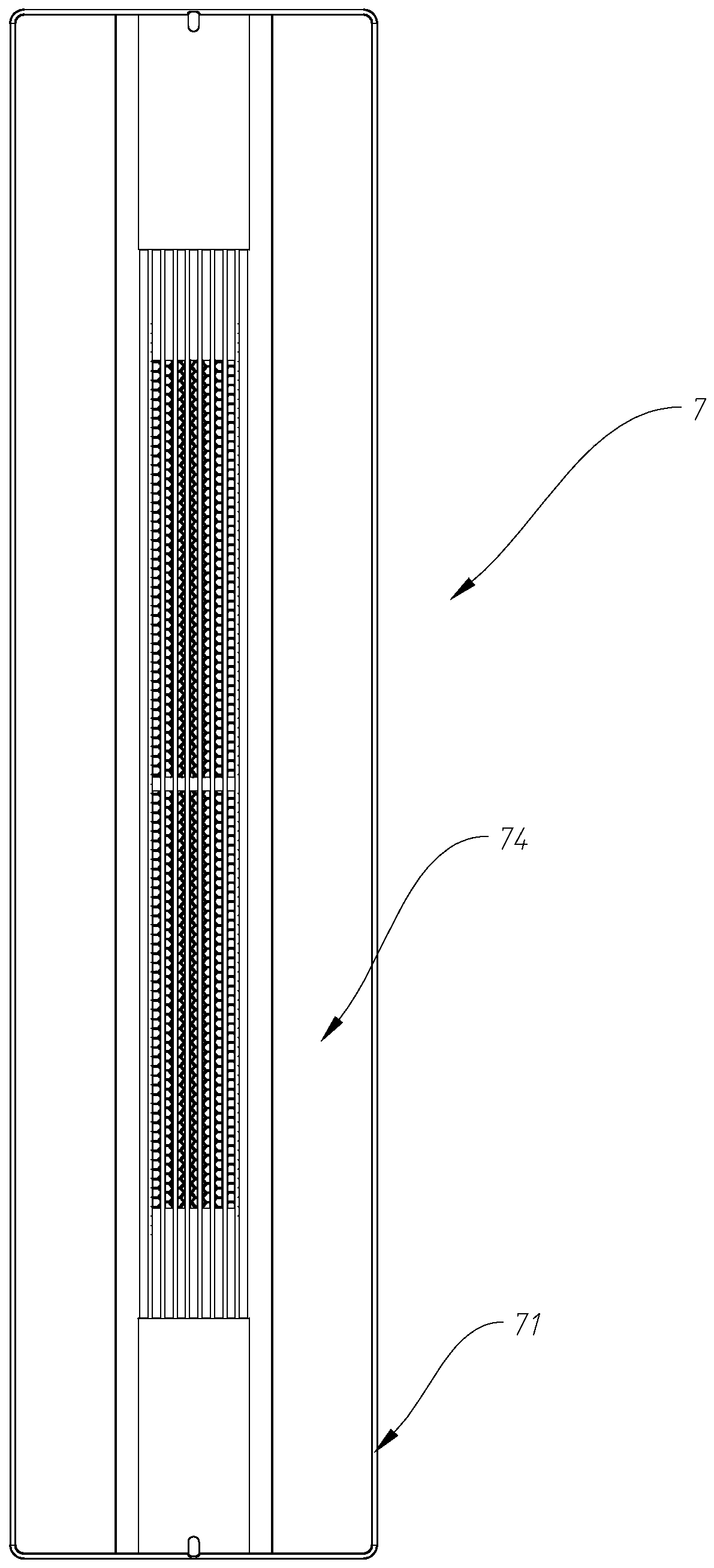

[0118] The width of the panel 74 is E; the cavity width of the accommodating cavity is F, and the distance between the first folded edge 711 and the second folded edge 712 is H; said H

[0119] A specific embodiment of the structure of the elastic member 77 of the present invention:

[0120] The elastic member 77 is a strip-shaped sponge or a strip connected to a spring;

[0121] Change to the plug-in mode, when inserting the light guide assembly 72, the accommodating cavity space of the hemming member 71 is relatively large, and the light guide assembly 72 can be inserted into the accommodating cavity without wear; when the panel 74 is inserted again, the accommodating cavity The remaining space is small, and at the same time, in order to avoid the shaking of the panel 74 after being placed, an elastic member 77 protruding from the light guide assembly is provided. 74 to effectively limit the position of the panel 74 to avoid shaking. At the same time, the side end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com