Cable clamping device for coal mining

A clamping device and cable technology, applied in transportation and packaging, cleaning methods and tools, cleaning methods using tools, etc., can solve the problems of easy mutual scratches, aging and deformation, etc., so as to avoid excessive pressure and improve Effect, the effect of increased bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

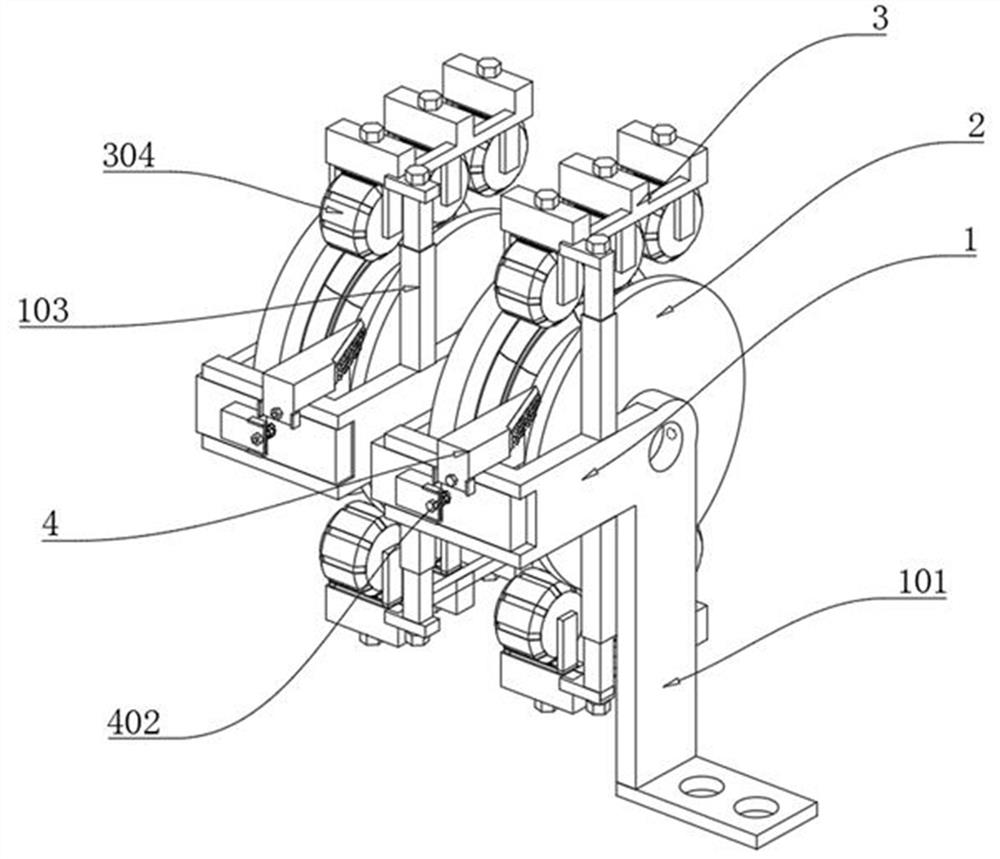

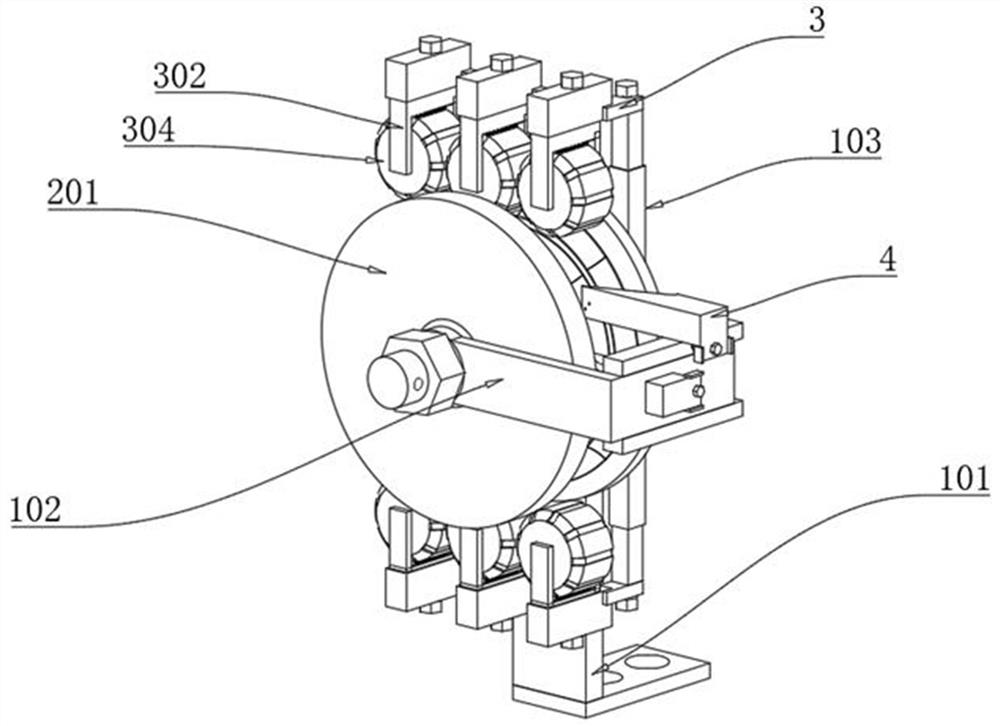

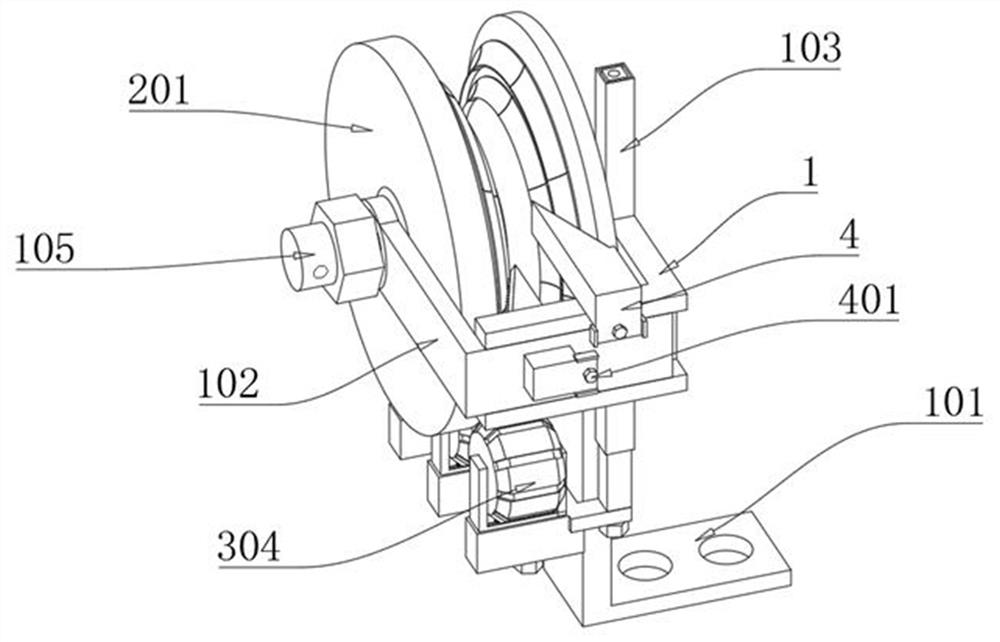

[0031] Example 1: Please refer to Figure 1 to Figure 10 :

[0032]In another embodiment, the lower fixing frame 101 is not provided in one main frame body 1, so that the main frame body 1 without the lower fixing frame 101 is not provided with the lower fixing frame 101 through the head end of the lead screw 105 and the circular recess in the middle of the main frame body 1. The grooves are connected through and fixed by screws, so that the plurality of main frame bodies 1 are connected in parallel with each other, and the plurality of main frame bodies 1 are arranged side by side.

[0033] refer to Figure 1 to Figure 10 , the main fixed bevel wheel 2 includes a secondary fixed bevel wheel 201, an inner arc strip 202 and a rear support shrapnel 203, the front faces of the main fixed bevel wheel 2 and the secondary fixed bevel wheel 201 are oppositely arranged, the main fixed bevel wheel 2 and the auxiliary fixed bevel The front of the bevel wheel 201 is provided with an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com