Buffering device for flexible sheet membranes and wastewater filtering module with same

A buffering device and film technology, applied in osmosis/dialysis water/sewage treatment, membrane technology, semi-permeable membrane separation, etc. The strength and quality of the soft film film can achieve the effect of facilitating the smooth filtration of water, improving the connection efficiency, and improving the strength and quality of the film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

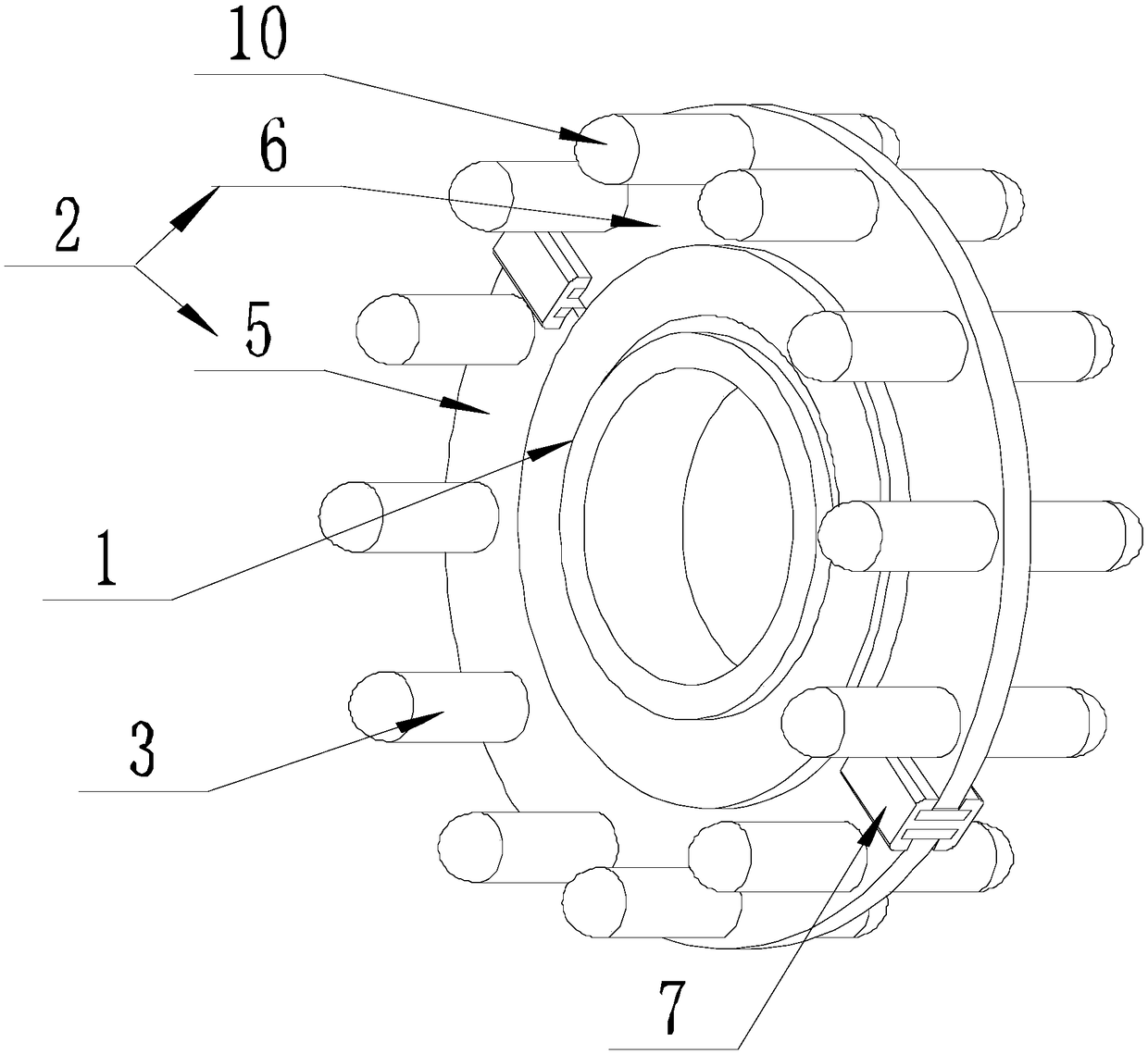

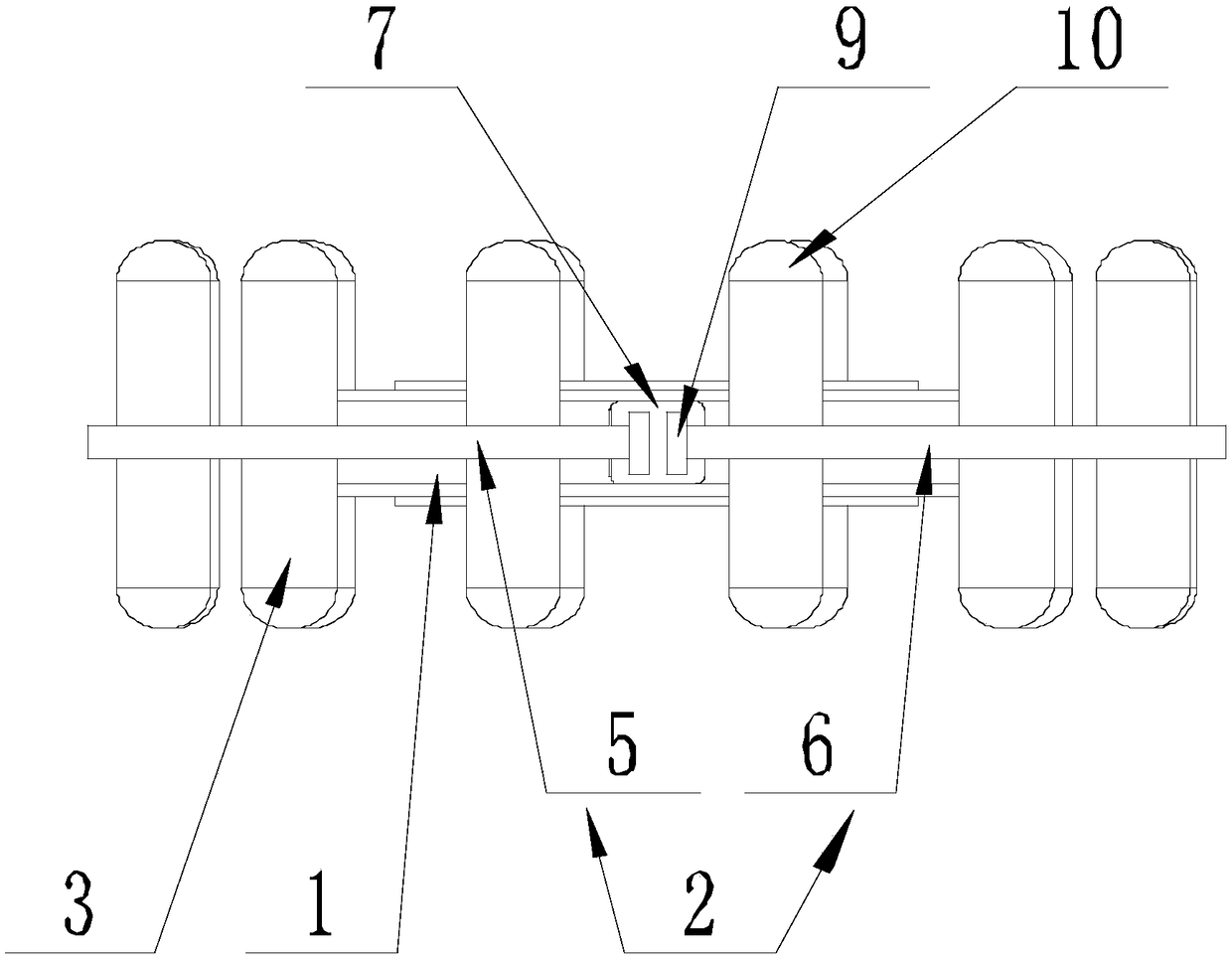

[0047] Such as Figure 1-Figure 6 As shown, a kind of cushioning device for film film of the present invention and a sewage filtration module with the buffering device include a positioning ring 1, and a vibration-damping ring 2 is set on the side wall of the positioning ring 1, and the vibration-damping ring The axis of 2 is concentric with the axis of positioning ring 1, and elastic members 3 are arranged on the end faces of vibration damping ring 2.

[0048] On the permeable pipe, two adjacent positioning rings 1 fix and clamp the film between them, so the positioning ring 1 is located between the two adjacent film films, and the elastic member 3 is far away from the damping ring One end of 2 is in contact with the corresponding film.

[0049] When the film shakes, due to the setting of the elastic member 3, it reduces the shaking amplitude of the part of the film close to the positioning ring, and buffers the shaking, reducing the stress on the part of the film clamped by...

Embodiment 2

[0051] This embodiment is based on the first embodiment, and further explains the installation of the damping ring 2 .

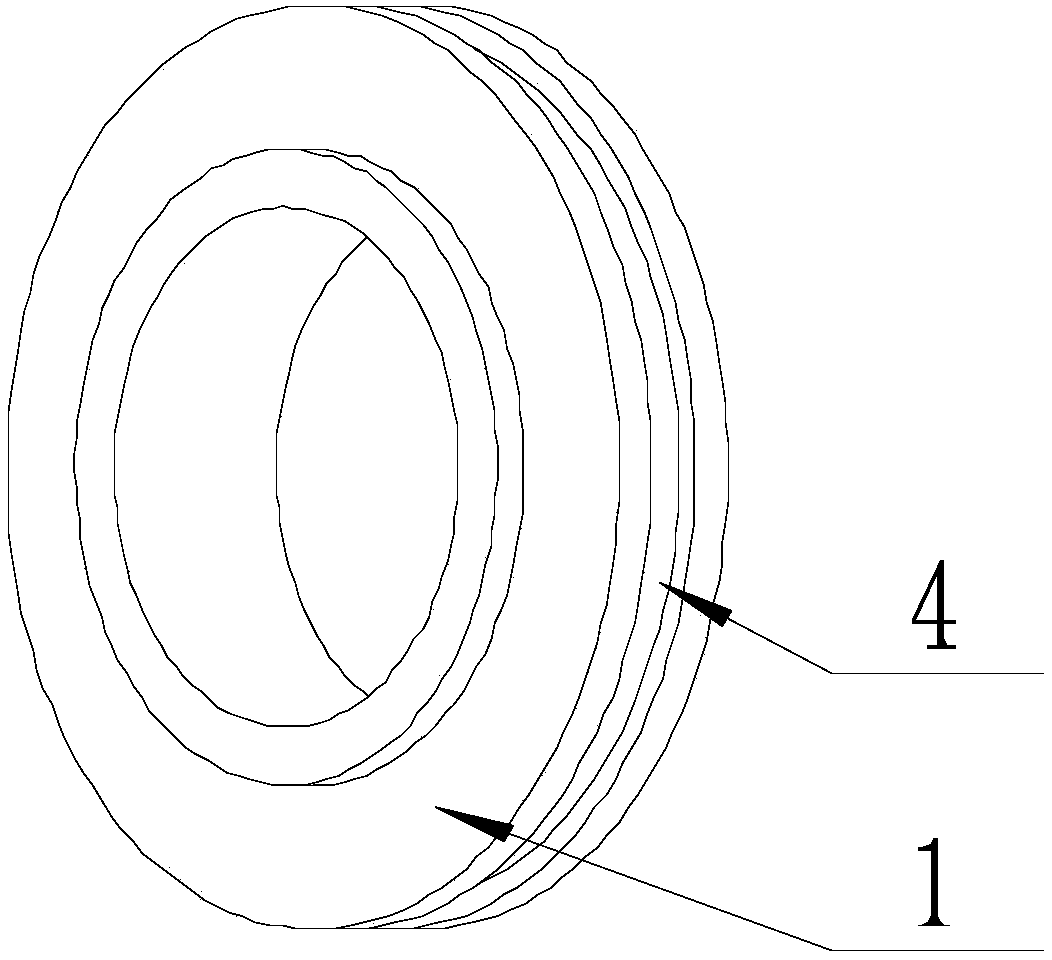

[0052] Such as Figure 1-Figure 6 As shown in the present invention, a buffer device for film film and a sewage filtration module with the buffer device, an annular groove 4 is arranged on the side wall of the positioning ring 1, and the axis of the annular groove 4 is aligned with the positioning ring 1 The axes coincide, and the diameter of the groove bottom of the annular groove 4 is consistent with the inner diameter of the damping ring 2, and the end of the damping ring 2 near the axis is inserted into the annular groove 4.

[0053] The setting of the annular groove 4 enables the vibration damping ring 2 to be fixed on the side wall of the annular groove 4, so as to prevent the vibration damping ring 2 from moving along the axis of the positioning ring 1, and then the contact surface between the vibration damping ring 2 and the positioning ring 1 Slidi...

Embodiment 3

[0063] This embodiment is based on Embodiment 1, and further explains the elastic member 3 .

[0064] Such as Figure 1-Figure 6 As shown, the present invention is a cushioning device for a film film and a sewage filtration module with the buffering device, and the elastic member 3 is an air bag, or a rubber strip, or a combination of the above two.

[0065] Further, the end of the elastic member 3 away from the damping ring 2 protrudes outward into a hemispherical surface 10 .

[0066] Further, each end surface of the vibration damping ring 2 is provided with 12 elastic pieces 3 .

[0067] Due to the setting of the elastic member 3, the vibration amplitude of the film film is reduced; therefore, in order to improve the effect of shaking off the slag deposited on the surface in order to improve the aeration of the film film, the vibration frequency of the film film can be increased, and then the original aeration effect can be maintained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com