Double front axle structure with lifting axle for heavy goods vehicle

A double front axle and front axle technology, applied in vehicle components, elastic suspension, suspension and other directions, can solve the problems of tire wear, sliding wear of the second front axle, and the inability of the second front axle to lift, etc., so as to reduce the weight of the vehicle , the effect of reducing wear and avoiding sliding wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

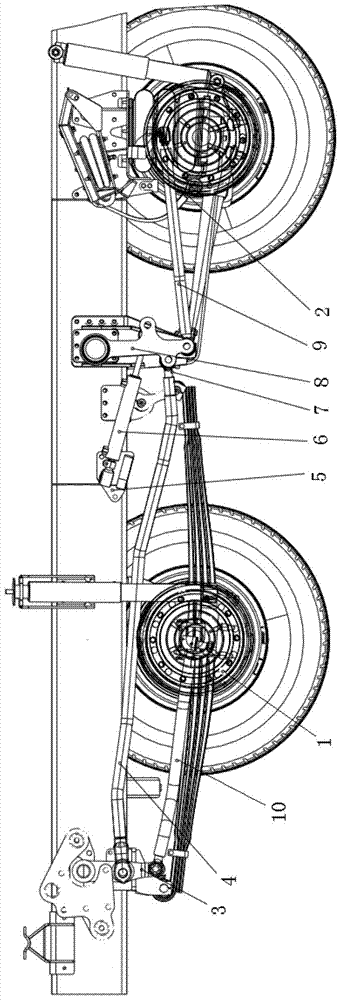

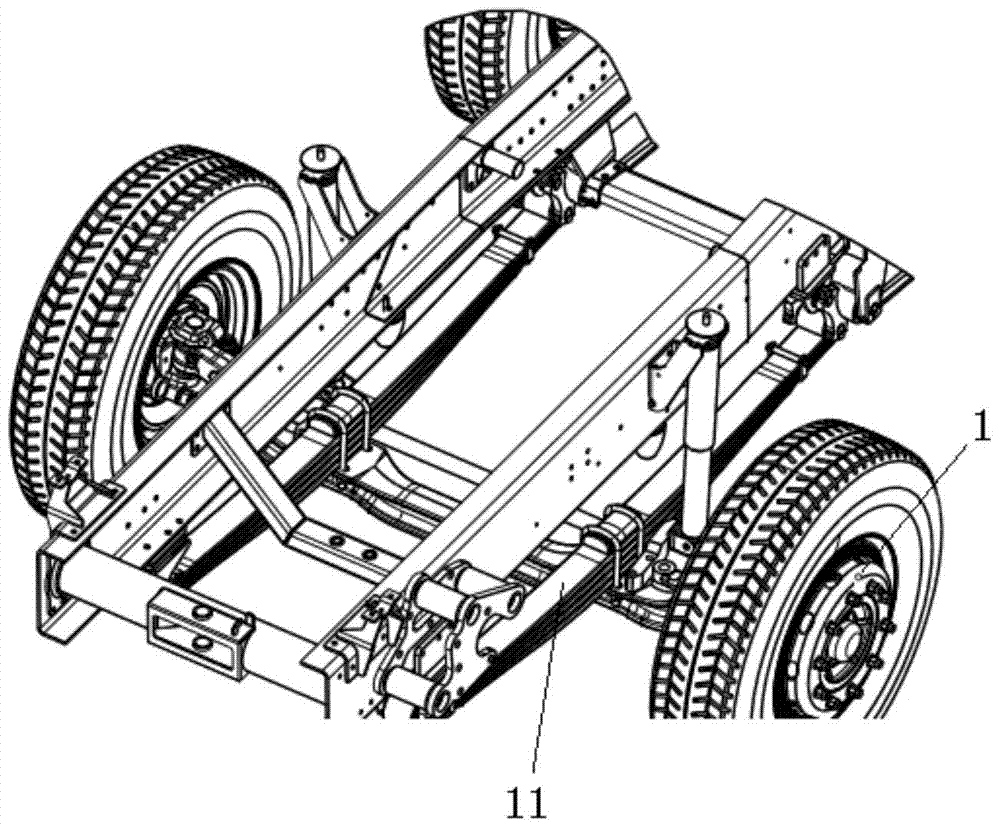

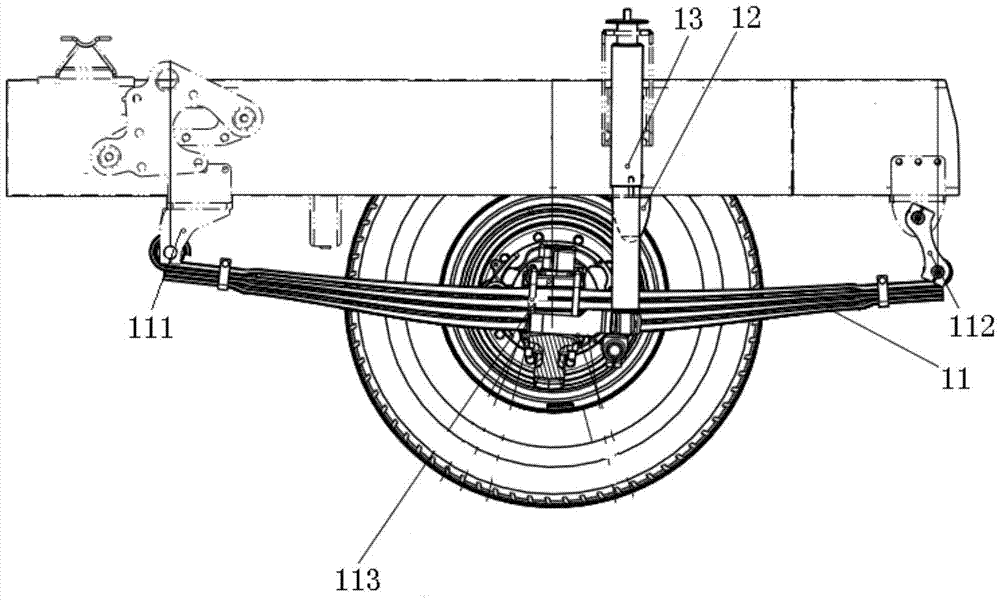

[0036] The invention provides a double front axle structure with lifting axles of a heavy goods vehicle, such as Figure 1 to Figure 5 As shown, it includes the first front axle 1, the second front axle 2, the first front axle steering rod assembly, the steering knuckle arm of the steering machine, the first front axle leaf spring, the second front axle lifting airbag, the airbag spring 23, The second front axle lifting bracket, the second front axle lifting cable, the second front axle leaf spring; also includes the second front axle pull rod assembly.

[0037] In this application, the first front axle steering tie rod assembly includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com