Conductor spacer rotation wire clip

A technology of spacer rods and rotary wires, which is applied in the direction of the device for maintaining the distance between parallel conductors and the mechanical vibration attenuation device. It can solve the problems of tower collapse, wire breakage, and inability to rotate relative to each other, so as to reduce maintenance and replacement and prolong service life. , to avoid the effect of sliding wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

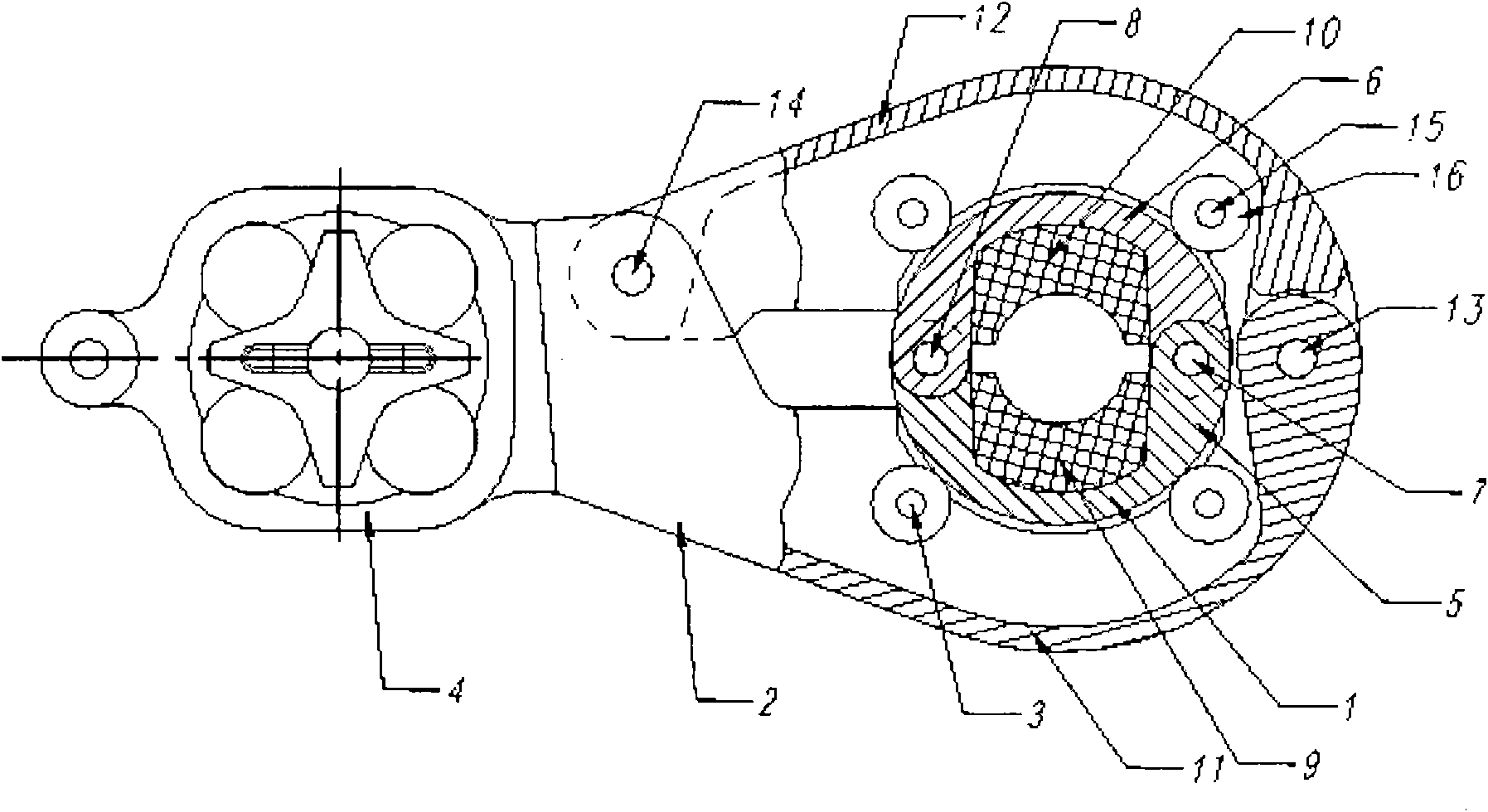

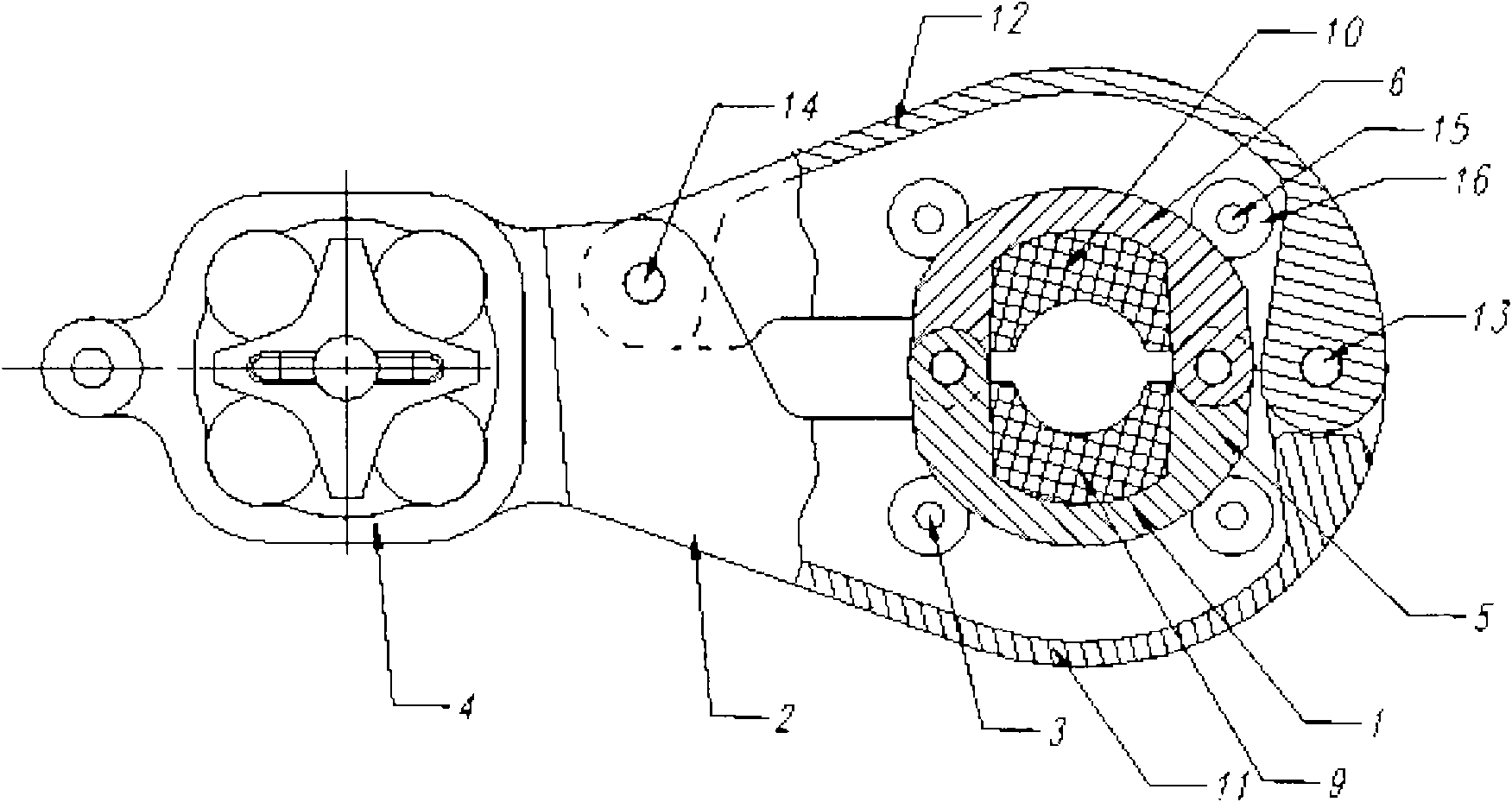

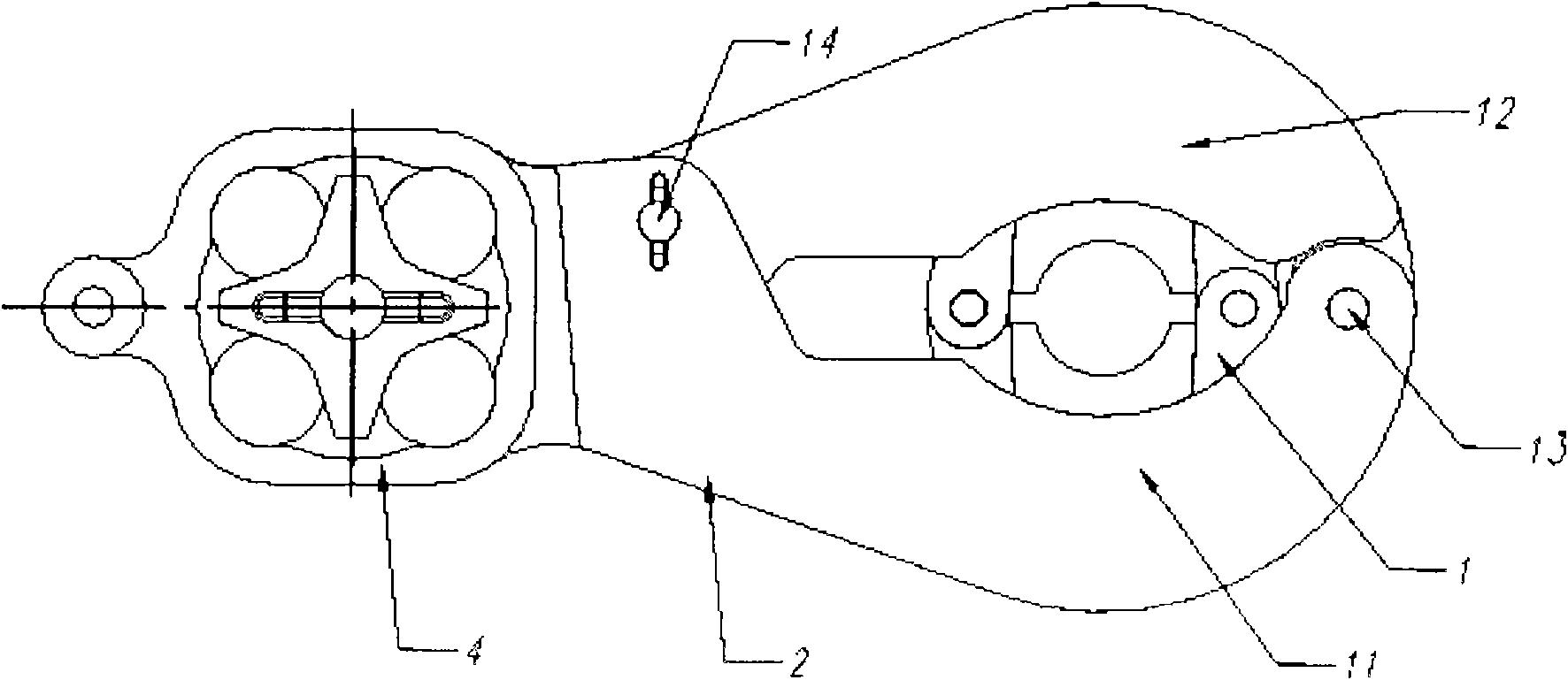

[0028] Now in conjunction with the preferred embodiment shown in the accompanying drawings, the structure of the present invention will be further described.

[0029] Depend on Figure 1-5 It can be seen that the spacer bar rotary clamp of the present invention is mainly composed of a center line clamp 1, a pincer arm 2 and several rollers 3. The center line clamp 1 is provided with a crimping groove for fixing and holding the wire. One end of the pincer arm 2 is a pincer buckle formed by two pincer clamps 11 and 12. The center line is fixed by several rollers 3 installed inside. The clamp 1 is fixed in the pincer buckle, and the center line clamp 1 can rotate around the wire in the pincer buckle of the pincer arm 2, so the wire clamped in it has a degree of freedom of rotation, so that the wire is eccentrically covered with ice. Under the eccentric force, the central line clamp 1 can be freely twisted, and eccentric icing cannot be formed in the end, so as to achieve the pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com