Seal device

A sealing device and sealing lip technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of reduced sealing capacity of the sealing device, increased wear, and decreased sealing capacity, so as to prevent the decrease of sealing capacity and reduce sliding resistance , the effect of preventing sliding wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, a sealing device according to a preferred embodiment of the present invention will be described in detail with reference to the accompanying drawings. Each drawing described below is made according to the design drawing.

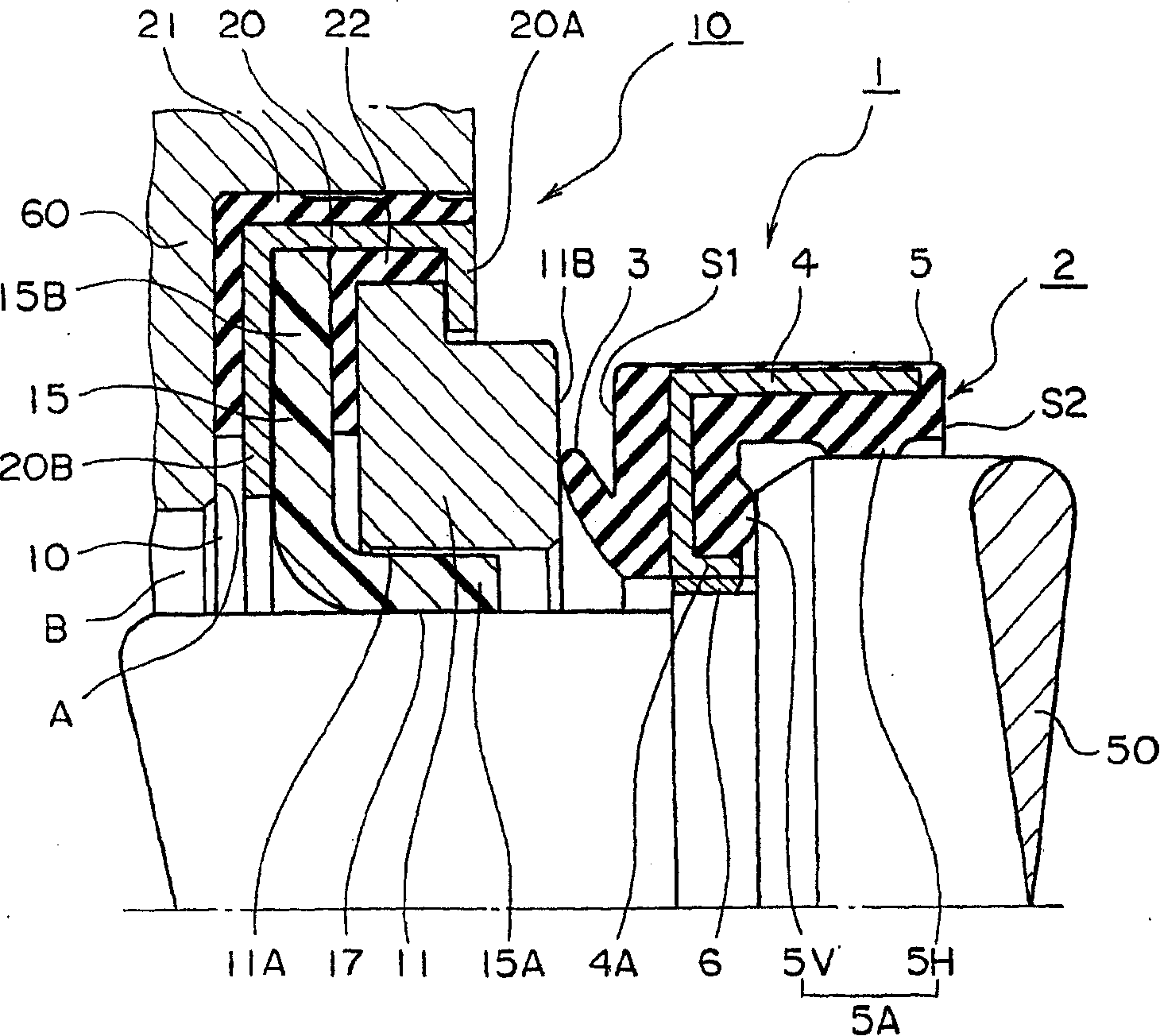

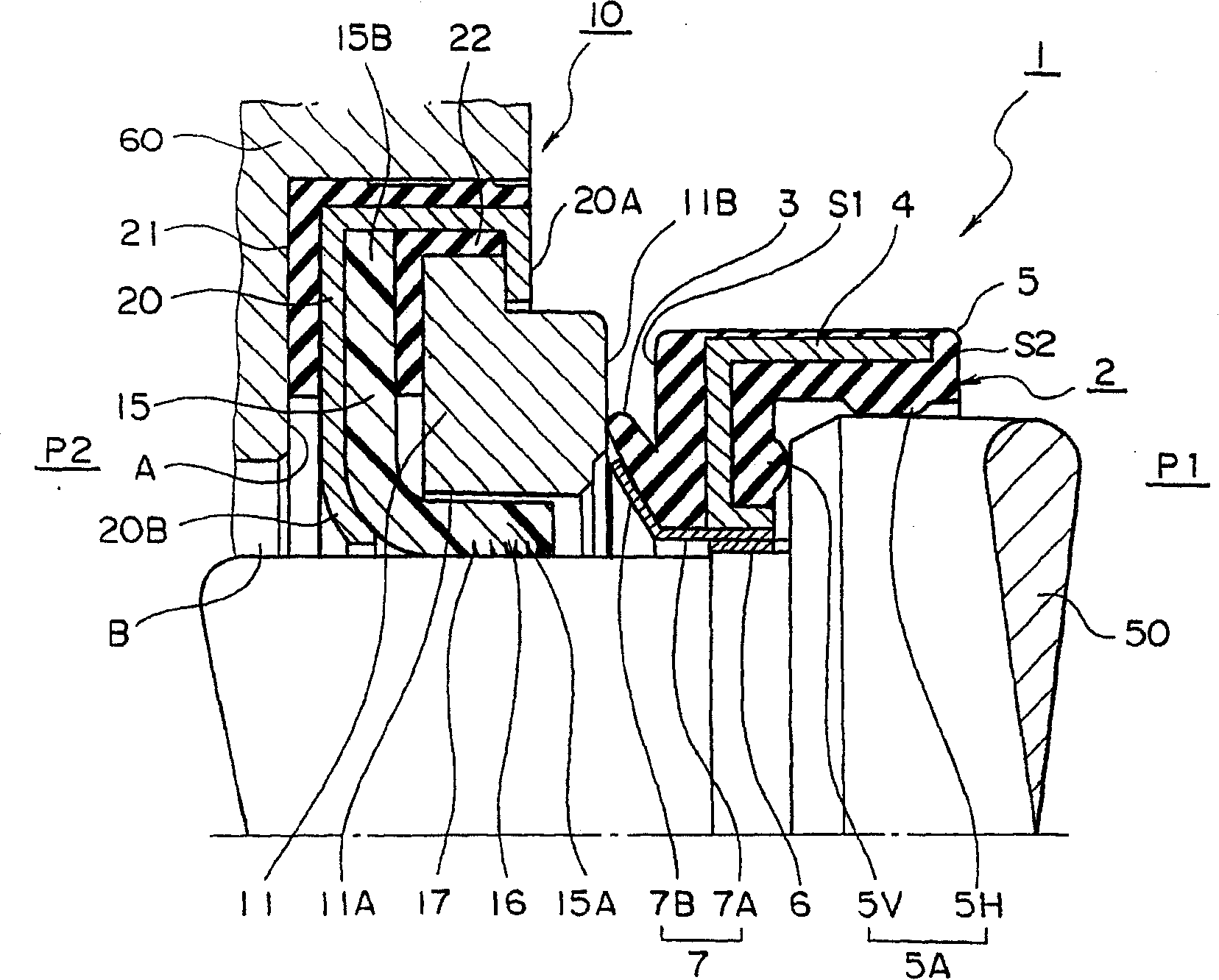

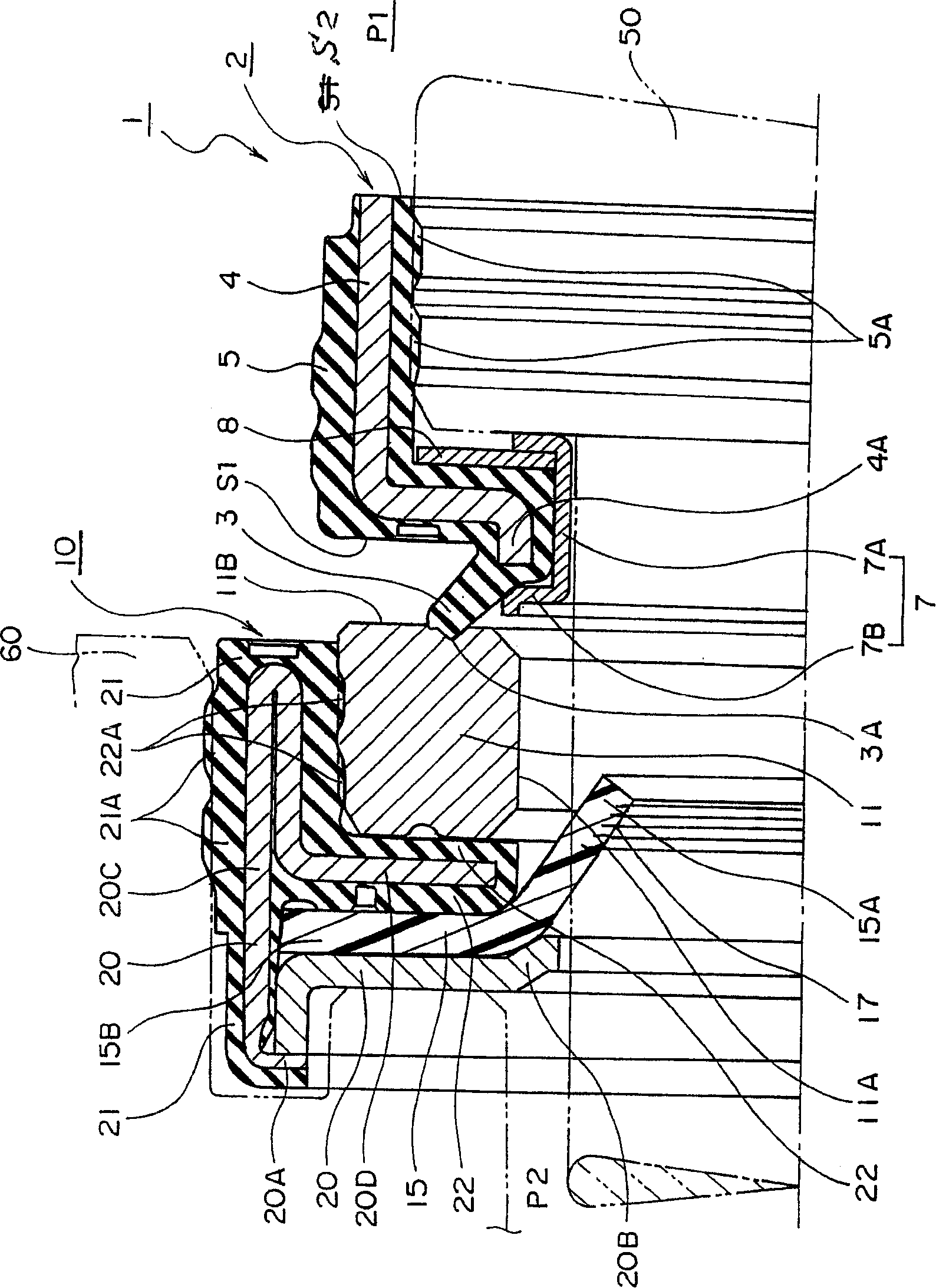

[0044] figure 1 It is a half cross-sectional view showing a sealing device 1 according to a preferred embodiment of the present invention.

[0045] figure 1 Among them, the sealing device 1 is formed by combining the end face seal 2 and the sealing part 10 to form a pair. In the seal portion 10, the seal ring 11 and the seal lip 15 are main constituent members.

[0046] The cross-section of the end face seal 2 is L-shaped, forming an end face seal body 5 . A protruding lip 3 extending outward in a V-shaped cross section is formed at one end of the end face sealing body 5 . In addition, the inner peripheral surface and the side surface of the end sealing body 5 are formed with a peripheral surface seal portion 5H and a side surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com