Ink oscillating device for offset machine

A technology for offset printing machines and inking rollers, which is applied to printing machines, general parts of printing machinery, printing, etc., can solve the problem of short service life and complexity; the second is a composite type, and the outer shell of the inking roller The public sleeve has a spiral groove on it, and balls are installed in the groove, so as to separate from the fixed bush installed on the inner wall of the outer shell of the ink roller, and the ball is attached to the ring groove of the fixed bush, and the fixed bush passes through The ball bearing and the inking roller shaft are installed together. When the outer shell of the inking roller is driven by power to rotate in the circumferential direction, it will affect the transmission accuracy and life of the inking gear, so as to achieve long service life, simple structure and avoid sliding wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

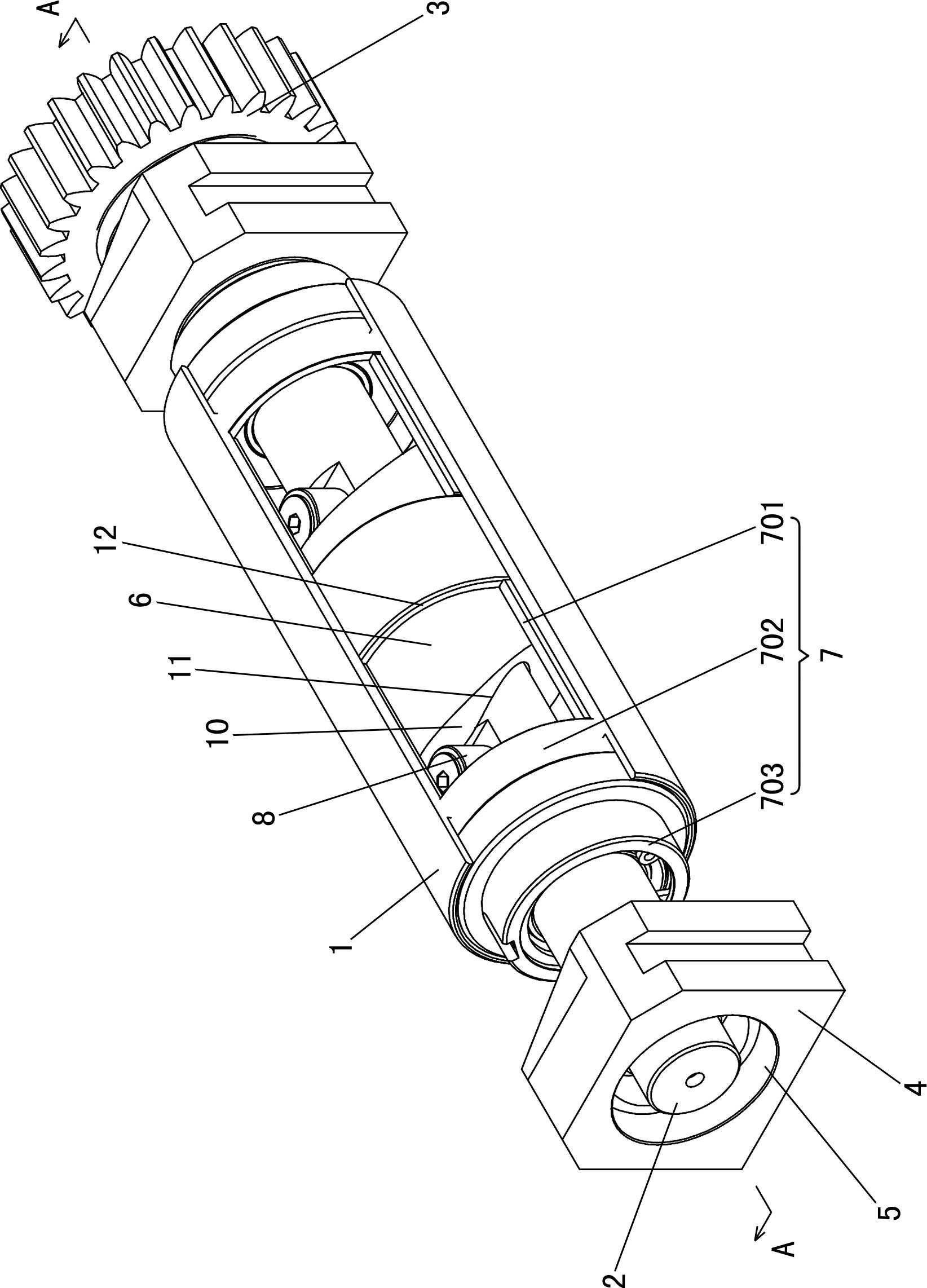

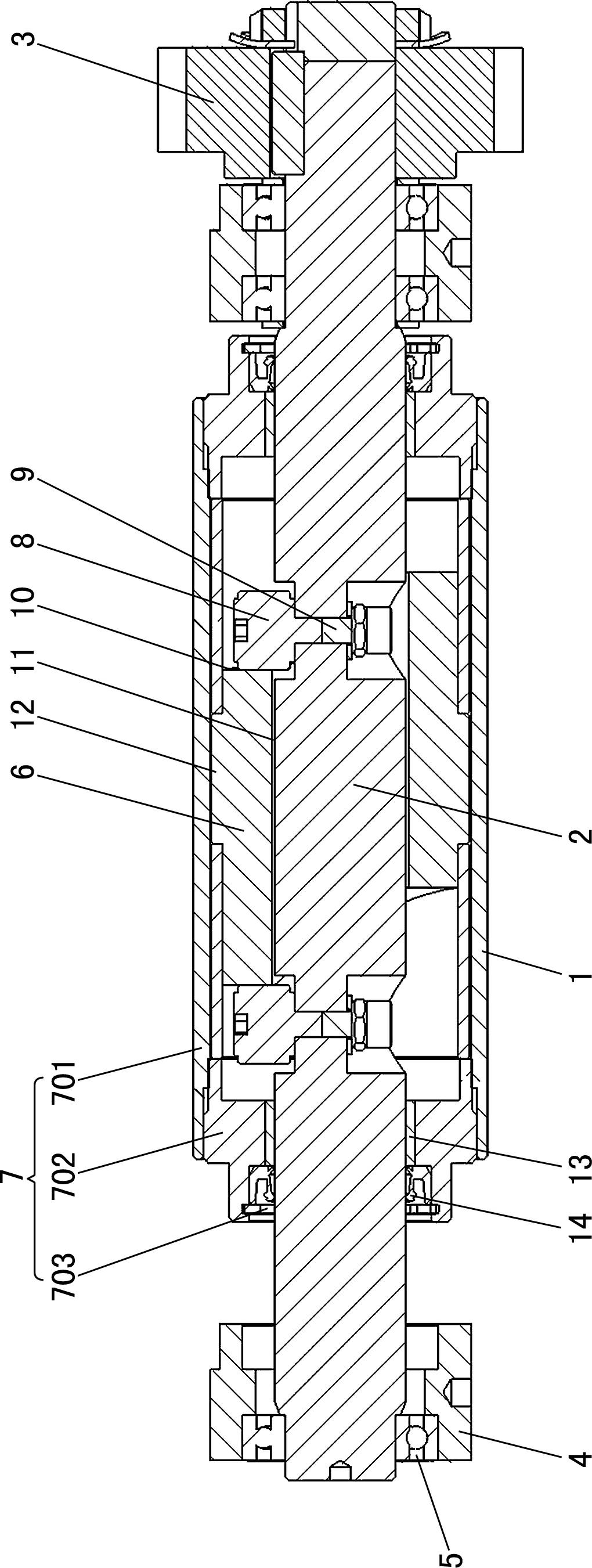

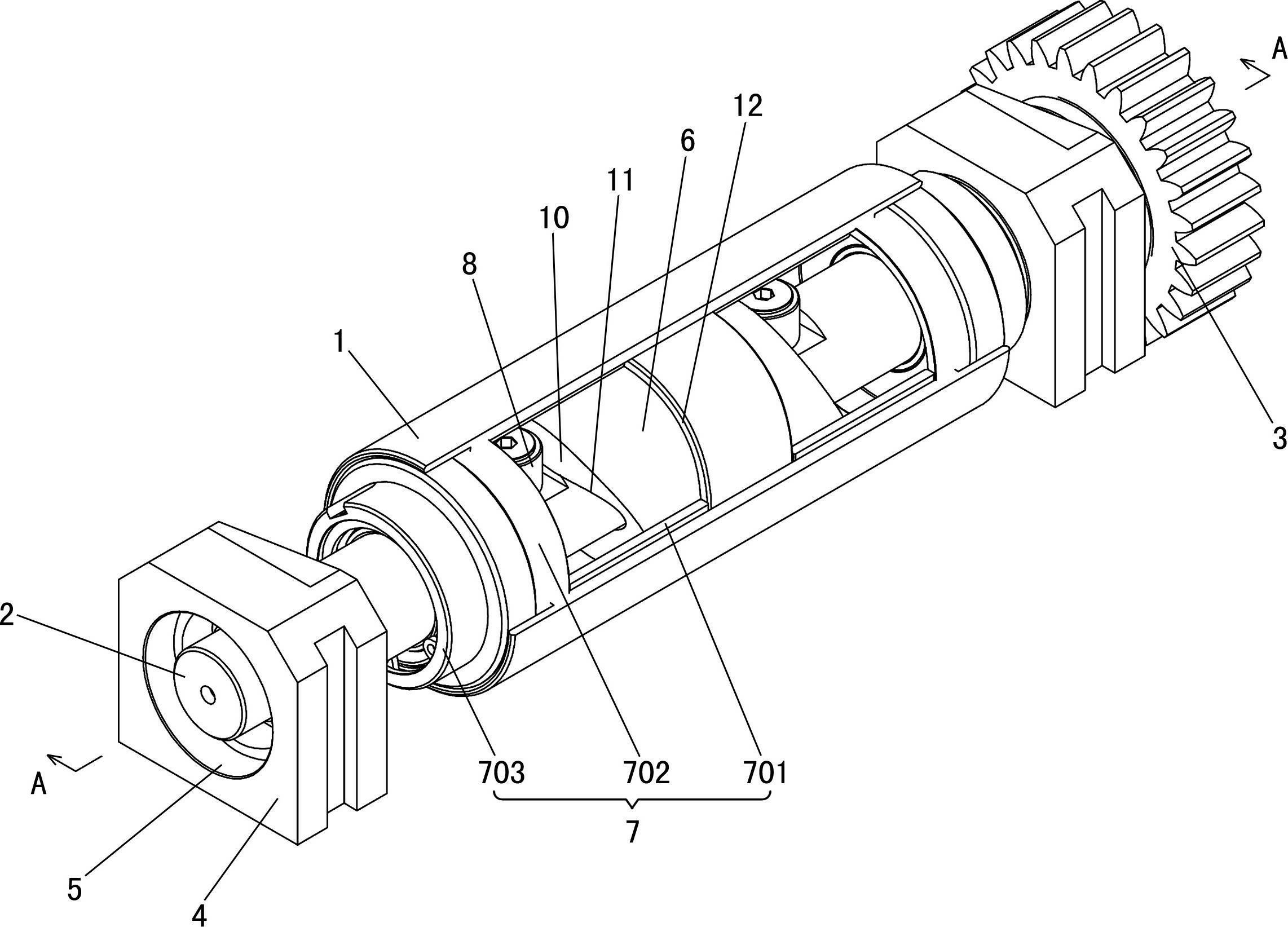

[0012] Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

[0013] Such as figure 1 and figure 2 As shown, the inking device of this offset printing machine includes an inking roller 1, an inking roller shaft 2, an inking gear 3, two bearing seats 4, two bearings 5, an end cylindrical cam 6, a fastening mechanism 7, two A cam roller 8 and two roller connecting shafts 9; the string ink roller shaft 2 is in the inner chamber of the string ink roller 1, and the two ends of the string ink roller shaft 2 are respectively installed on the bearing housing 4 through the bearing 5; the string ink roller The gear 3 is in transmission connection with one end of the ink roller rotating shaft 2; the end face cylindrical cam 6 has two end faces 10, and along the axial direction of the end face cylindrical cam 6, the distances between two corresponding points on the two end faces 10 are equal; the end fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com