A 90° elbow with deflector ribs

A technology of elbows and rib plates, applied in the directions of elbows, pipe elements, siphons, etc., can solve the problems of large increase in water flow resistance, and achieve the effect of small resistance loss, reducing resistance loss and improving hydraulic efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the drawings and descriptions of the drawings.

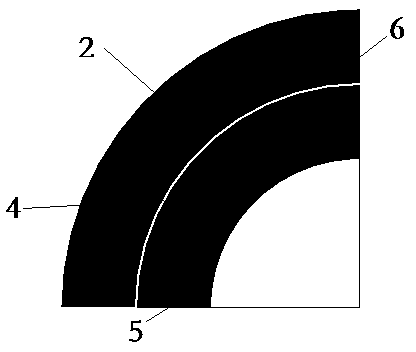

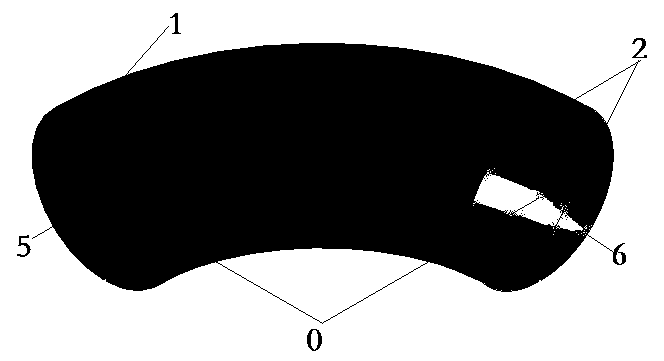

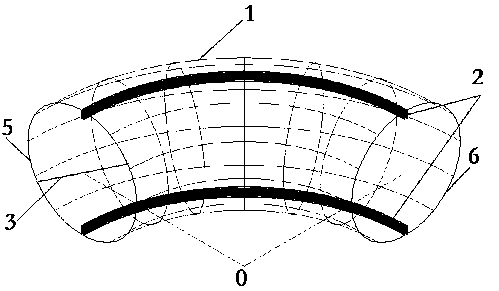

[0043] A 90° elbow with flow guiding ribs, comprising an elbow 1, the elbow 1 includes a pipe inlet 5, an outlet 6, a water inlet straight pipe 7, and a water outlet straight pipe 8, and the pipe inlet 5 is connected to the water inlet straight pipe. Pipe 7, pipe outlet 6 is connected to the water outlet straight pipe 8, the pipe inlet 5 of the elbow 1 is aligned with the center of the water inlet straight pipe 7, and the outlet 6 is aligned with the center of the water outlet straight pipe 8; perpendicular to the center of the elbow 1 Each section of the arc 4 is a circular section, and the diameter of each circular section is equal to the diameter of the circular section of the inlet and outlet of the elbow 1;

[0044] On both sides of the inner wall of the elbow 1, there are flow guide ribs 2 symmetrically arranged. The thickness of the flow guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com