A heat exchanger core for heat exchange of two or more fluids

A technology for heat exchangers and heat exchange fluids, applied in the direction of indirect heat exchangers, heat exchanger types, heat exchange equipment, etc., can solve the problems of inability to realize heat exchange of various fluids, and achieve the extension of contact time and the range of temperature reduction The effect of increasing and increasing the cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

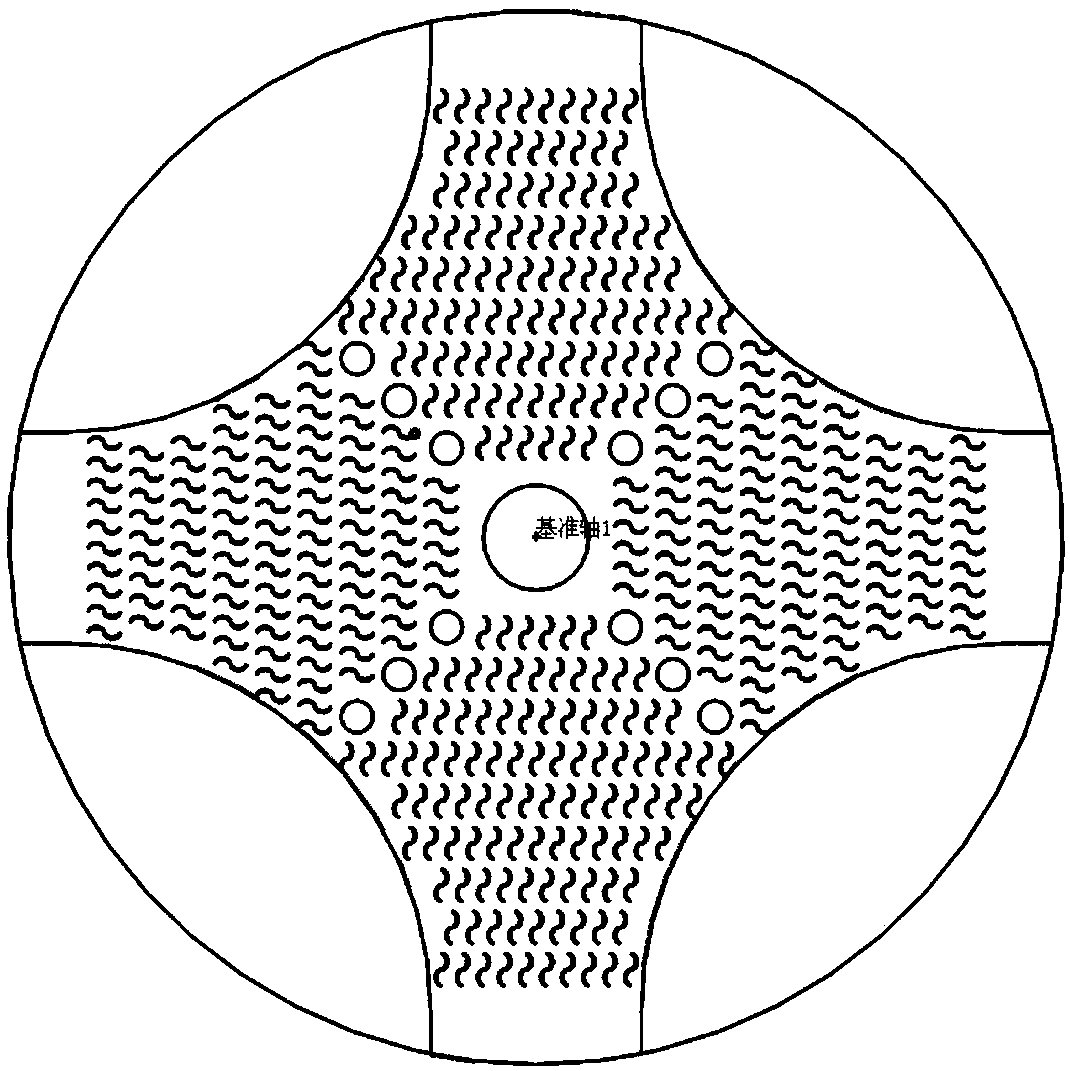

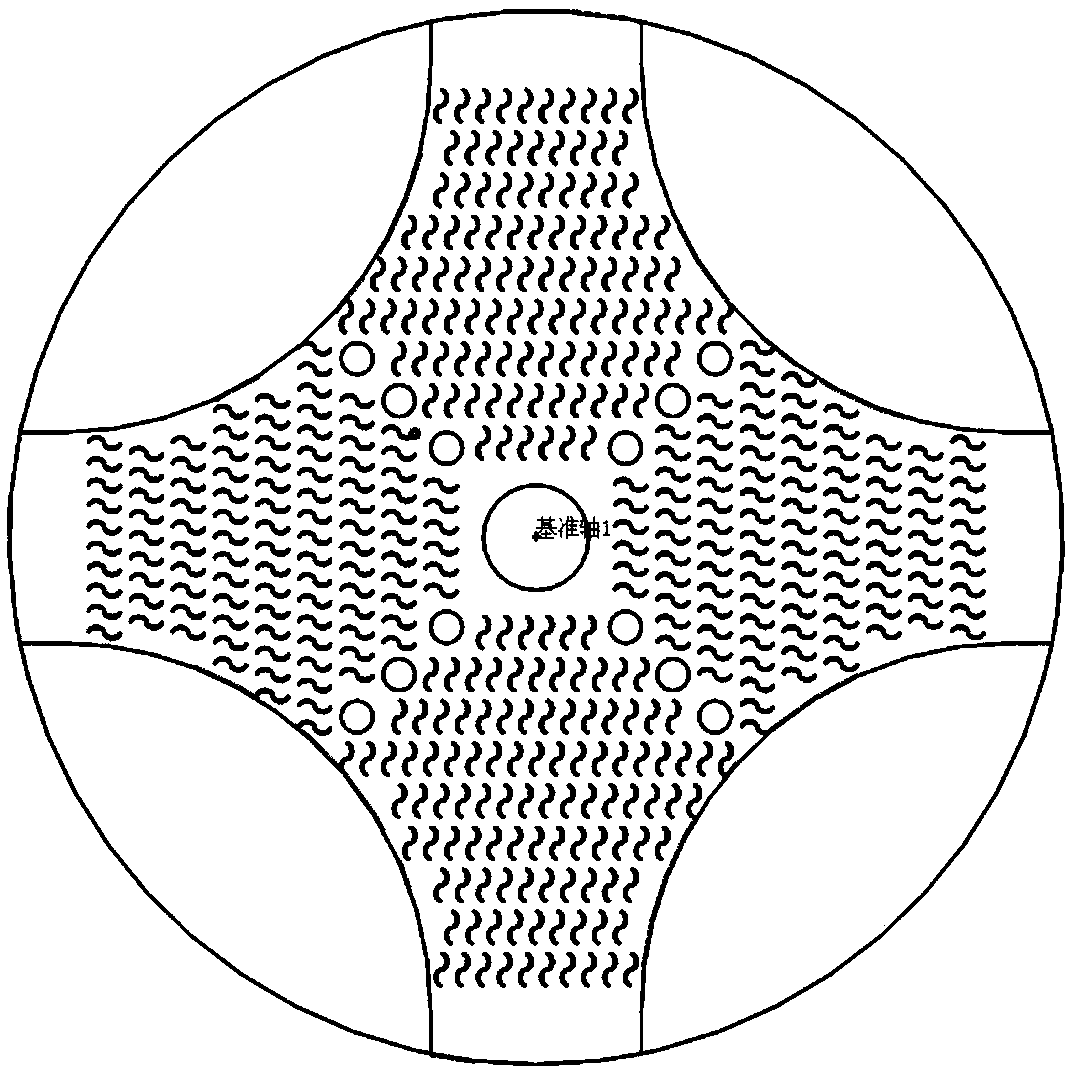

[0032] A heat exchanger core used for heat exchange of two or more fluids, including two heat exchange plate groups, which are formed by alternately stacking two heat exchange plate groups; each heat exchange plate group carries a A heat exchange fluid, that is, the core of the heat exchanger includes two heat exchange fluids; the heat exchange plates include cold plates and hot plates; The heat exchange flow channel processed above; the heat exchange flow channel on the cold plate base is arc-edge cross-shaped, such as figure 1 As shown, the fluid through hole is set at the center of the arc-edge cross-shaped heat exchange flow channel; the bottom of the arc-edge cross-shaped heat exchange flow channel is provided with a plurality of S-shaped curved grooves. The four ports of the arc-edge cross-shaped heat exchange runner on the cold plate are located on the side of the cold plate base, as the inlet of the heat exchange fluid; the fluid through holes are used as ports corresp...

Embodiment 2

[0038]The difference between embodiment 2 and embodiment 1 is that a heat exchanger core for heat exchange of two or more fluids includes 5 heat exchange plate groups, and 5 heat exchange plate groups are stacked alternately Among them, the alternate stacking of heat exchange plate groups means that the heat exchange plate group adjacent to any heat exchange plate group in the core of the heat exchanger is any heat exchange plate except itself Group. Each heat exchange plate group carries a heat exchange fluid, that is, the core of the heat exchanger includes five heat exchange fluids. The four ports of the arc-edge cross-shaped heat exchange runner on the cold plate are located on the side of the cold plate base, as the inlet of the heat exchange fluid; the fluid through holes are used as ports corresponding to the properties of the heat exchange runner on the cold plate The outlet of the heat exchange fluid; the exposed two heat exchange plate groups after being alternately...

Embodiment 3

[0041] The difference between embodiment 3 and embodiment 1 and embodiment 2 is that a heat exchanger core for heat exchange of more than two fluids includes 10 heat exchange plate groups, and consists of 10 heat exchange plates Sheet groups are stacked alternately, where the alternate stacking of heat exchange plate groups means that the heat exchange plate group adjacent to any heat exchange plate group in the core of the heat exchanger is any other than itself. Heat exchange plate group. Each heat exchange plate group carries a heat exchange fluid, that is, the core of the heat exchanger includes 10 heat exchange fluids. Cover plates are arranged outside the two exposed heat exchange plate groups after being alternately stacked, and there is a partition or no partition between any cover plate and the adjacent heat exchange plate group. The heat exchange channels of the cold plate base and the hot plate base are all located on both sides of the heat exchange plate (such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com