Tubular heat exchanger with locating pin

A tubular heat exchanger and positioning pin technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve problems such as poor sealing effect, and achieve good recovery effect, good effect and efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

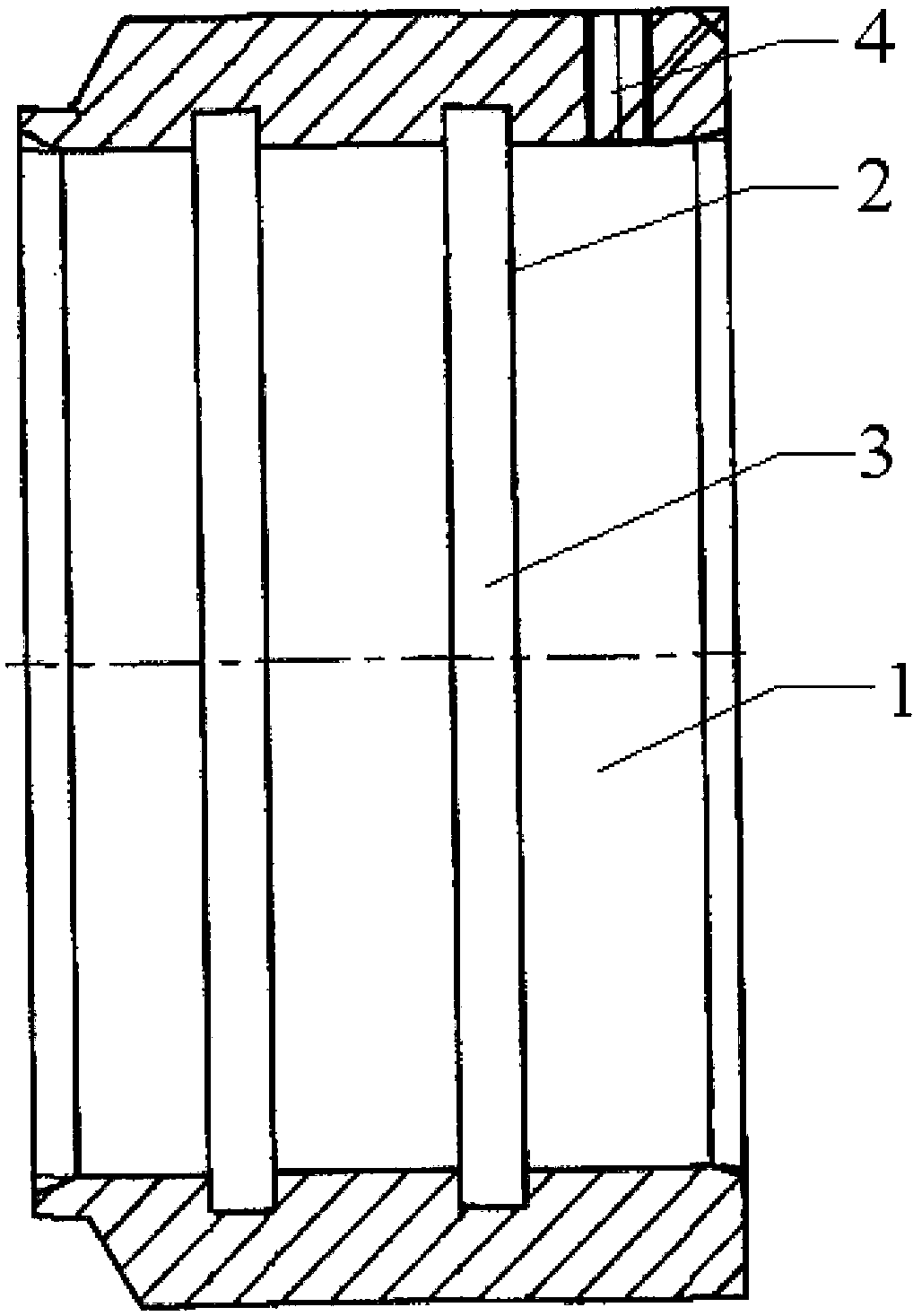

[0026] A tubular heat exchanger with positioning pins, a number of parallel tubes are arranged in the shell of the heat exchanger, the two ends of the tubes are fixedly connected with the head of the heat exchanger, a transverse baffle is set in the shell, and the columns A longitudinal baffle is set inside the tube, and the structure of the head 1 is as follows: figure 1 As shown, there are grooves 2 and positioning pins 4 for fixing the tubes and longitudinal baffles on the head 1. There are two grooves 2 and they are arranged in parallel. Rubber sealing ring 3. The positioning pin 4 is arranged on the side of the sealing head 1 . The transverse baffles arranged in the casing separate the tube arrays into heat exchange channels. In addition, fins may also be arranged in the heat exchange channel, and both sides of the fins are sealed by sealing strips. The fins that can be used are straight fins, porous fins, serrated fins and corrugated fins.

[0027] Said, parallel set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com